This is a great question about component sizing.

I'll mention that those solenoids (Prestolite 15-487) are rated 100A and only two are switched on at a time. So it's not a question that's limited to the DC88. I smoked stock solenoids after all.

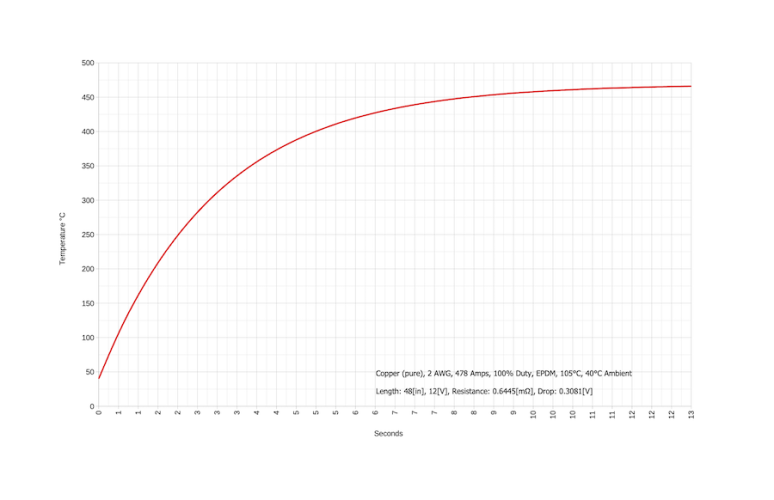

Also the question relates to the size of cable you need to use and why Warn supplying 4AWG and 2AWG is OK when the charts seem to indicate you should use 1/0AWG.

The first thing to know is the 9000 lbs and 478A values are based on locked rotor values. That means the point where the maximum torque is developed (thus max current) but this for an electric motor is at zero RPM. So no practical work is done, so this is a baseline but not the only value.

Also you'll notice immediate that 478A isn't even going to match the motor rating. Warn calls the motor on an XD9000 a 4.5HP motor. The electrical equivalent is watts and is related to HP as 1HP = 746W. If you remember the electrical formula for watts it's voltage times current.

So if you take 4.5HP that should be 3,357 watts, what at nominal 12V is 280 amps. That's the motor's working rating. If you ask it to do work at 478A that's 7.69HP. So the real world doesn't match the datasheet maximums.

The motor will do 478A/7.69HP but only very briefly right as it stalls or starts. It can't really do more than 4.5HP for any significant length of time.

The trickery here is that Warn (and they are not unique) know that you aren't going to ask this winch to do 9000 lbs of work continuously, all the time. There are winches designed for that and they are physically larger. There's reasons why it's this way but suffice to say it's also why

recovery winches are NOT designed for overhead or critical uses. If it was an XD9000 would be given a WLL much less. I don't know exactly, but it would surely be under 1,000 lbs and I'm sure there's braking or auto latching features it would need as well.

So back to how we can use this contactor.

We've already established that an XD9000 is really only a ~5000 lbs winch (based on 4.5HP, 280A). Now even that number is going to be subject to duty cycle and actual use.

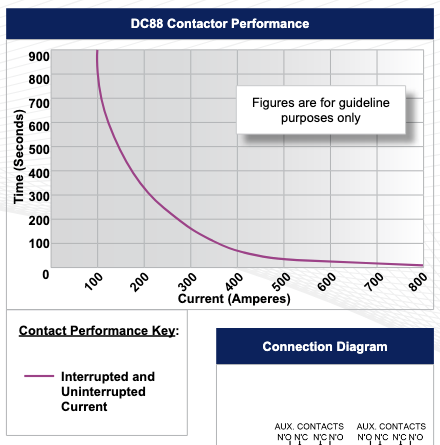

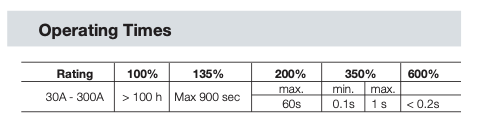

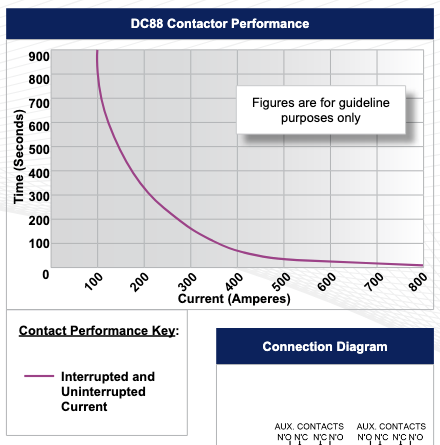

The numbers Albright give are indefinite, meaning no time limit. At 30% duty cycle but with no limit it'll do 185A forever. It's about how much heat builds up and can be shed over time. They assume that 30% duty might mean you run it 3 minutes on, 7 minutes off. Or 18 minutes on, 42 minutes off. Or who knows. It's just given that you have some amount of off time for the on time to arrive at a duty cycle.

So if you know and limit overall use the device can handle more power. So if we use a more realistic ~280A max and figure normally we ask it do even that much it might be for say 5 minutes, 300 seconds. Then we're right on the curve, maybe slightly aggressive. But we also know that at that much current the motor itself is going to be hot and need a rest, too, so it's not an unreasonable assumption to think our average power is lower and times are probably less aggressive.

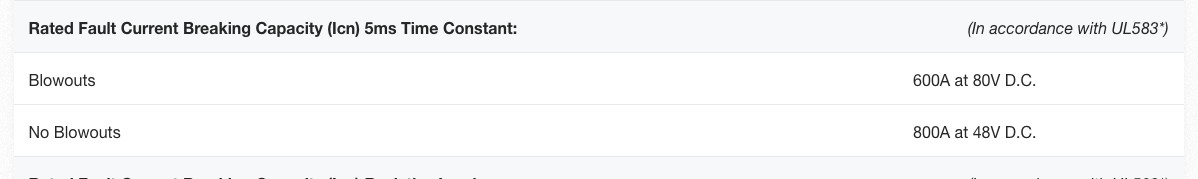

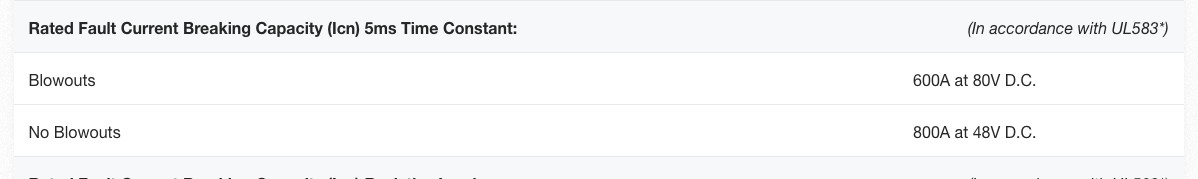

There's another spec you need to look at. The maximum interrupt value.

For a DC88 that's 600A. So if you do stall at 478A but let go right away the contactor shouldn't weld itself closed.

I'll leave cable sizing (and fuse/breaker if you choose to use them) for another discussion but the same principle applies. You don't ask the motor to consume 478A forever without a break. So if you figure 280A is your real peak and even that isn't constant you'll find that you really don't need a 1/0AWG or 500A fuse. It's basically about

average heating, not peak values. We are a little loose with values because the whole system is a balancing act of theoretical capacity vs actual use cases.

We don't really need 9,000 lbs of winch just like Toyota says your engine has 239HP but 99% of the time you use more like 50 or 100. Good thing, too, since asking your engine to run at 100% rated HP constantly would kill it fast, too.