-

UPDATED LOCATION DUE TO FORECAST OF RAIN: MAY 2024 CLUB MEETING

UPDATED LOCATION DUE TO FORECAST OF RAIN: MAY 2024 CLUB MEETING

Hi Guest: The next RS meeting will be Wednesday, May 1, 2024 at 7:30 p.m. The meeting will be held indoors at the fabulous Golden Gate Canyon Grange. Click here for directions. We'll be talking ColoYota Expo and Cruise Moab.

⦿ If you are eligible for club membership, please fill out an application in advance of the meeting and bring it with you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil and Coolant Mixing

- Thread starter DaveInDenver

- Start date

DaveInDenver

Rising Sun Ham Guru

tacomaJoe73

Rising Sun Member

can I take the over at a 3% chance of full torque? keep giving r' hell..Welp, sent and tapped. I lost a couple of mm of thread at the top of and the bolt wobble is pretty concerning. I'm giving about a 2% chance it'll make it to full torque.

View attachment 128458

fjc man

Rising Sun Member

A Timesert in the original head bolt size would probably be your best bet.

MDH33

Hard Core 4+

Good job Dave! It will hold. 💪

DaveInDenver

Rising Sun Ham Guru

Tried to run a thread repair into it. It seemed better up until the bolt just stops, hard stop, about 1/2 way down. Tried to chase it and the tap also stops at the same point.

I'm afraid I've sufficiently toed the line on ruining the block. At this point there's no way to run a bolt in far enough to even have the bolt head touch the cylinder head, never mind get it to torque. Not sure what I do next since I don't really want to make a decision that totally eliminates a fix in place.

As a bonus feels like a broke a rib when I lost my footing on the ARB leaning over the engine. That friggin' hurt, I most definitely not a kid anymore.

I'm afraid I've sufficiently toed the line on ruining the block. At this point there's no way to run a bolt in far enough to even have the bolt head touch the cylinder head, never mind get it to torque. Not sure what I do next since I don't really want to make a decision that totally eliminates a fix in place.

As a bonus feels like a broke a rib when I lost my footing on the ARB leaning over the engine. That friggin' hurt, I most definitely not a kid anymore.

Last edited:

Agreed. I’ve had mixed luck with helicoils in this application. I e never had an issue with a timesert even though they are 10x the cost.A Timesert in the original head bolt size would probably be your best bet.

You need some new tools. Everybody likes buying new tools. 😜Agreed. I’ve had mixed luck with helicoils in this application. I e never had an issue with a timesert even though they are 10x the cost.

Also the last couple times I’ve done this on a block, I rented a mag base drill. It’s not necessary for the repair, but it makes it way less awkward to drill and it’s generally a lot more perpendicular to the block.

Good luck!! Don’t give up!!

Good luck!! Don’t give up!!

DaveInDenver

Rising Sun Ham Guru

Probably where I'm sitting now. Since the Heli-coil kit didn't work and I don't seem to be able to peel it out to try again. I'm going to leave it alone the rest of today and maybe for a while. I mentioned to Marco that I wish I could find a mag drill but couldn't find one yesterday to rent. There's some question as to how true it is at this point. I'm kind of leaning towards stepping back, seeing if I can get the right stuff in hand. A short block is financially an absolute no-go.Agreed. I’ve had mixed luck with helicoils in this application. I e never had an issue with a timesert even though they are 10x the cost.

Edit to add, you were posting while I was typing. Between maybe walking off center as well as maybe necking down the clear "right" answer is Time cert. It might not be necessary but all the thrashing about like a redneck isn't getting it any closer to being trailworthy and I'm getting pretty frustrated and that isn't helping.

Last edited:

Oh man with O&G and all the construction going on out there, someone surely has one for rent or to lend!Probably where I'm sitting now. Since the Heli-coil kit didn't work and I don't seem to be able to peel it out to try again. I'm going to leave it alone the rest of today and maybe for a while. I mentioned to Marco that I wish I could find a mag drill but couldn't find one yesterday to rent. There's some question as to how true it is at this point. I'm kind of leaning towards stepping back, seeing if I can get the right stuff in hand. A short block is financially an absolute no-go.

DaveInDenver

Rising Sun Ham Guru

We had some at Poma but they're all out in the field and I don't work there anymore to just use one in the shop. But yeah, they're out there but just gotta take a breather from running around like Dave The Headless Chicken.Oh man with O&G and all the construction going on out there, someone surely has one for rent or to lend!

DaveInDenver

Rising Sun Ham Guru

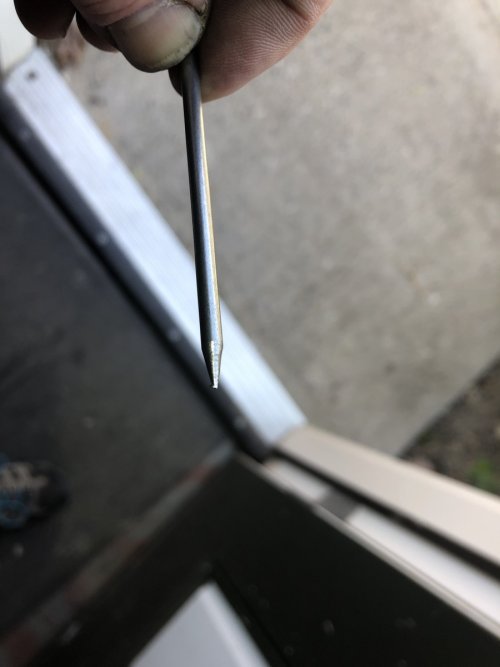

Got the hole cleaned up the other day and I can see the insert down in there. So trying to pick at it to get it to come out. Haven't found the right tool that will grab it.

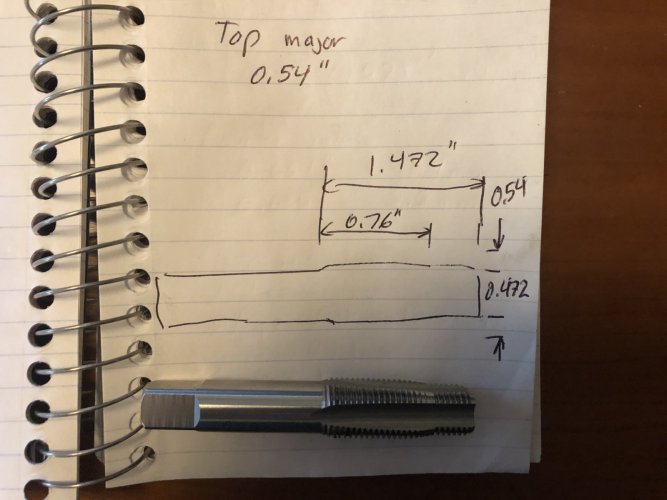

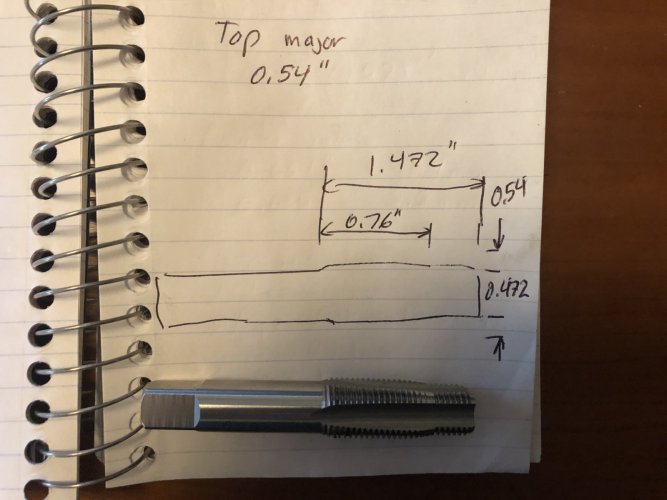

The thinking is if I can get the helicoil out then it might be possible to shorten the tap and get it to run down into the hole enough more so that the bolt will seat down enough to hold the head. The shoulder on the funky fix-a-thred tap has probably made a shelf where the bolt is bottoming about 1/4" too shallow.

The thinking is if I can get the helicoil out then it might be possible to shorten the tap and get it to run down into the hole enough more so that the bolt will seat down enough to hold the head. The shoulder on the funky fix-a-thred tap has probably made a shelf where the bolt is bottoming about 1/4" too shallow.

DaveInDenver

Rising Sun Ham Guru

tacomaJoe73

Rising Sun Member

time to go fishing afterwards, unwind.. you've got the hook now.Alright, actual positive ground. Got the old helicoil out so I can attempt to run the tap, maybe shorten it to get the new threads deeper, and set a new insert.

View attachment 128587

FWIW, modified 16d nails and a bench grinder and a needle nose FTW.

View attachment 128589

View attachment 128588

rover67

Rising Sun Member

don't maybe shorten it, shorten it FOR SURE. you need more (deeper) threads in there tapped to the insert's OD.

DaveInDenver

Rising Sun Ham Guru

@rover67 exactly. Ran it as made first until it solidly bottomed, cut the M12-1.25 guiding thread completely off. Used a thin wheel on the angle grinder, left the taper on the helicoil STI and dressed 'er up as nice as I could.

It aligned fine, cut a few more turns pretty nice, a little resistance but felt smooth like I expected. Set the coil in just below the surface, broke out the tang and even was able to fish it out of the hole.

Bolt bottoms in the block now, a solid couple of threads below the deck. This is what it's supposed to look like. I probably should've set the helicoil a little lower but it'll be fine.

It aligned fine, cut a few more turns pretty nice, a little resistance but felt smooth like I expected. Set the coil in just below the surface, broke out the tang and even was able to fish it out of the hole.

Bolt bottoms in the block now, a solid couple of threads below the deck. This is what it's supposed to look like. I probably should've set the helicoil a little lower but it'll be fine.

Last edited: