Maybe my old engine was just worked. But I’m happy to say the new engine definitely has a noticeable bump in power. Turbo will change the game.

-

NOVEMBER 2025 CLUB MEETING

NOVEMBER 2025 CLUB MEETING

Hi Guest: The next RS meeting will be Wednesday, Nov. 5, 2025 at 7:30 p.m.

LOCATION: The meeting will be held at Cruisers and Company. Click here for details and directions.

⦿ If you are eligible for club membership, please fill out an application in advance of the meeting and bring it with you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I think I may have ruined my engine (97 1fz)

- Thread starter coax

- Start date

I got my old “core” out of the trailer and on a stand today solo. That was a bitch without a hoist.

How did you manage that?!? Even with no head on there that thing is massive. Bonus points for not having a hoist and getting that accomplished!

I'm hoping to get eyes on the crank today or tomorrow...work was nuts so all i've gotten done is to pull one of the camshafts thus far But holy smokes when I pulled the caps/bolts there must have been some sort of oil/antisieze/etc that smelled HORRIBLE. Like worst smell I've ever smelt...like gear oil x50. I had to put on a respirator to keep working. I bet something in the bottom end got a bit hot when it ran out of oil and burned some stuff in there. Yuck!

But holy smokes when I pulled the caps/bolts there must have been some sort of oil/antisieze/etc that smelled HORRIBLE. Like worst smell I've ever smelt...like gear oil x50. I had to put on a respirator to keep working. I bet something in the bottom end got a bit hot when it ran out of oil and burned some stuff in there. Yuck!

I'm hoping to get eyes on the crank today or tomorrow...work was nuts so all i've gotten done is to pull one of the camshafts thus far

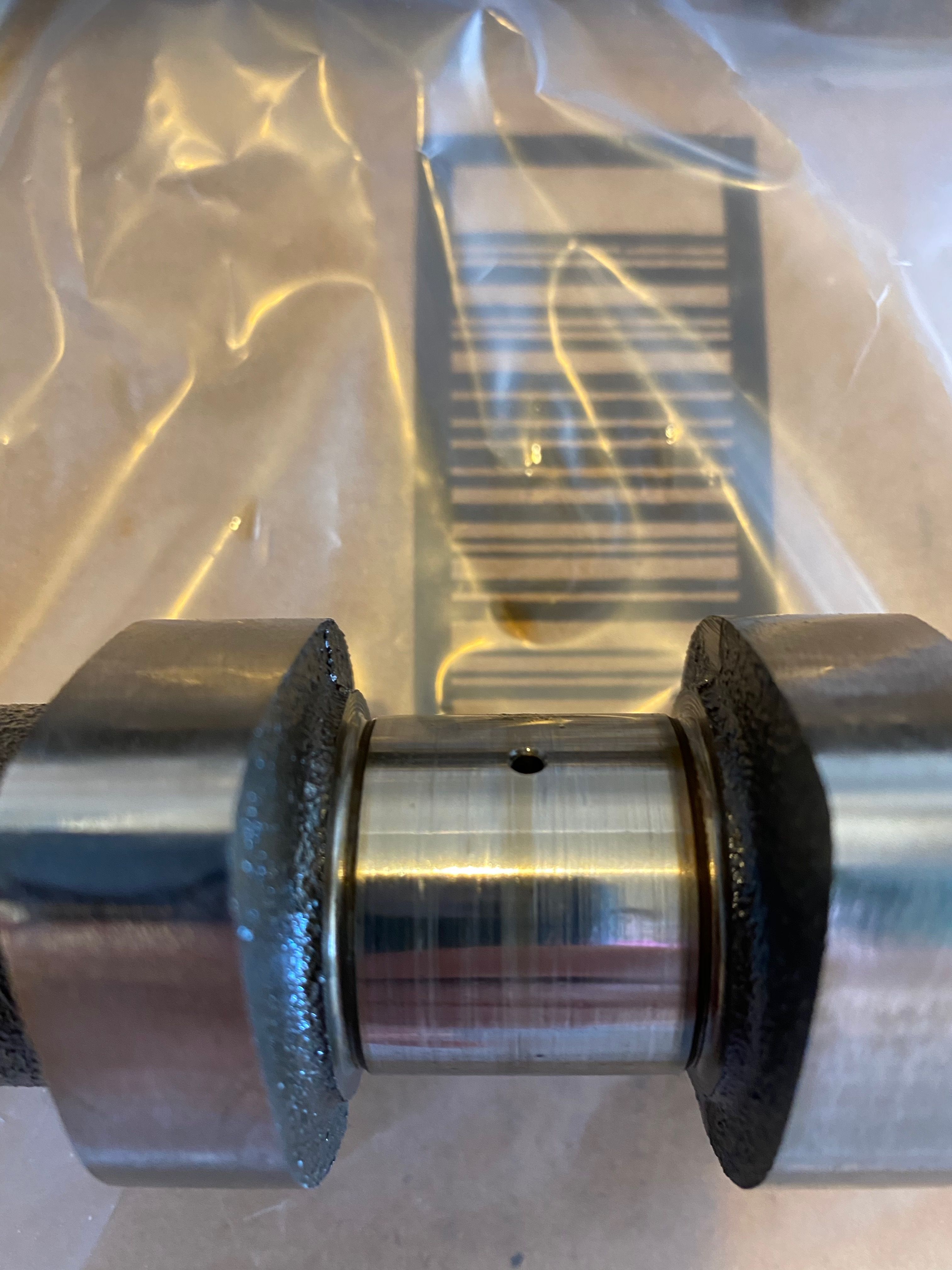

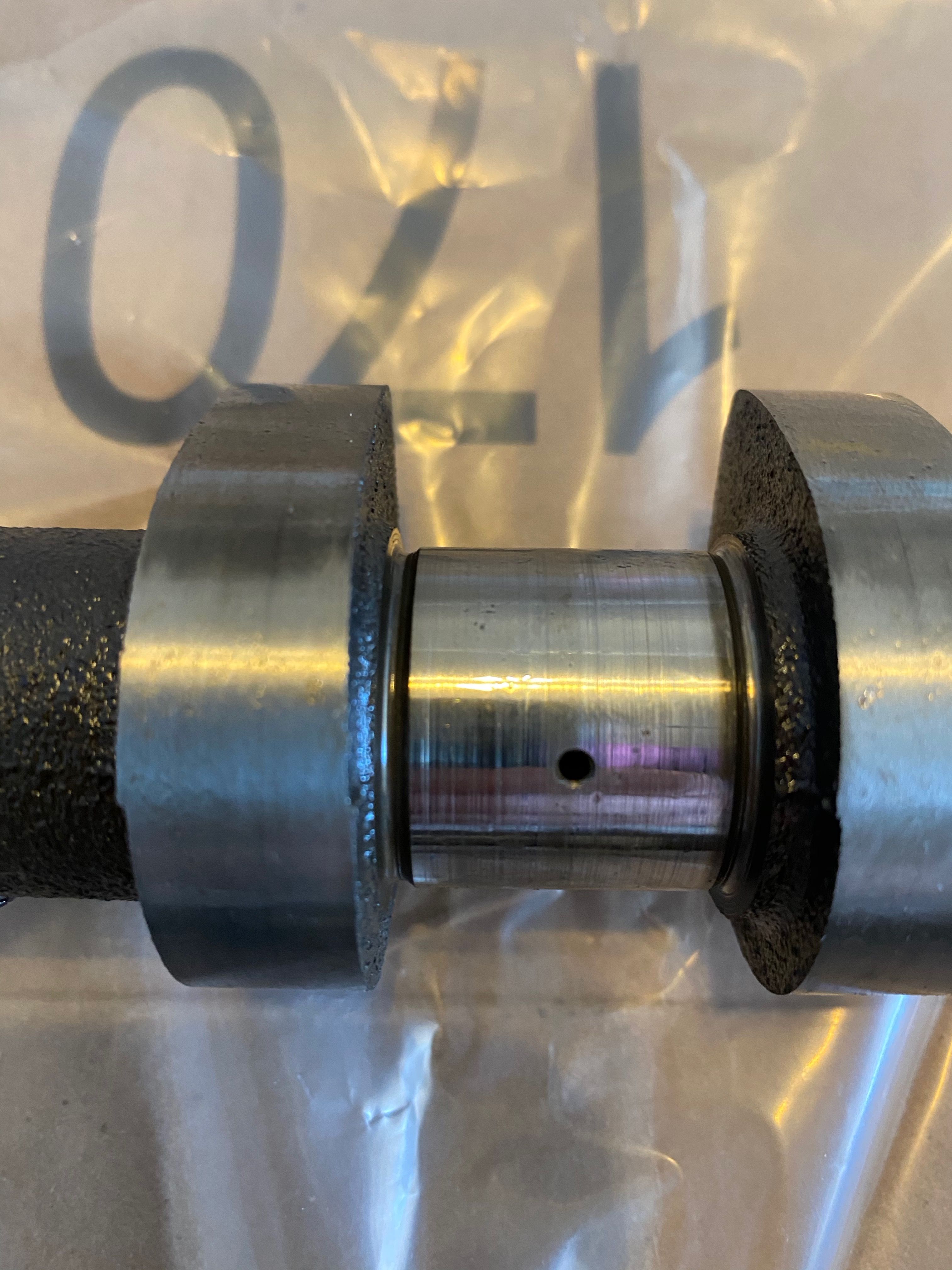

Ok could use some feedback from folks. Looking at the journals on the camshafts...there are are definitly some ridges in the metal. Enough at least on the exhaust cam shaft to catch a fingernail on. Oddly enough the bearing surface and caps are much nicer/smoother. How smooth should I expect the camshaft surfaces to be? Seems like they may be toast :|

A few pics:

A few pics:

dan1554

Rising Sun Member

Looks like some scoring but can't see it affecting anything seriously. I'd look for bent shims. Could be deeper issue if they're flat. Nothing obvious to me otherwise with my shadetree eye but thought I'd throw out a comment. Grains of rice and all.

One further update. Tore deeper into the engine. My current assessment having never done this before  Would love any input/logic check:

Would love any input/logic check:

Not all that much in the strainer.

One of the worst connecting rod bearings (#1 & #6 were the worst)

Other side of the connecting rod bearing

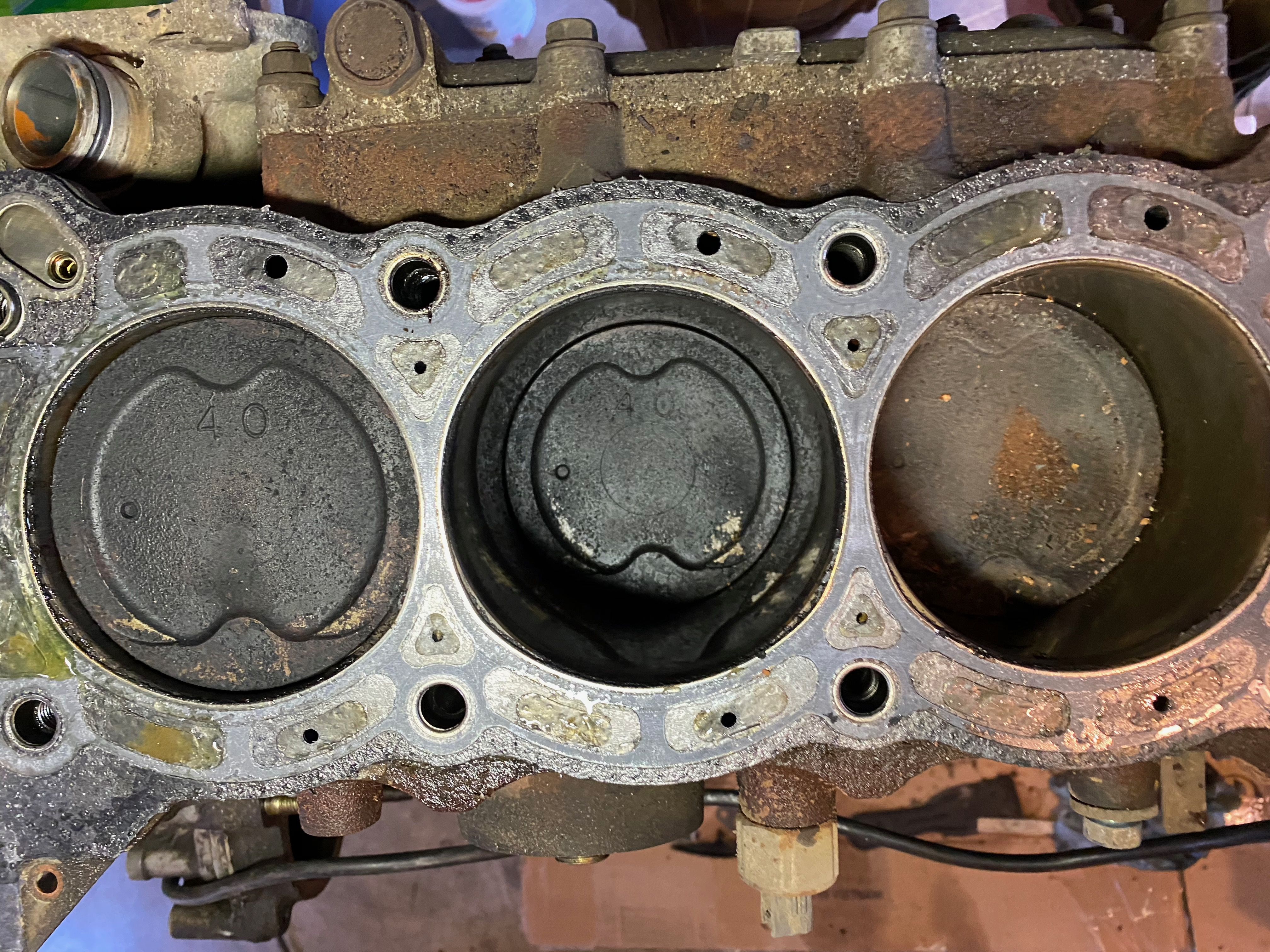

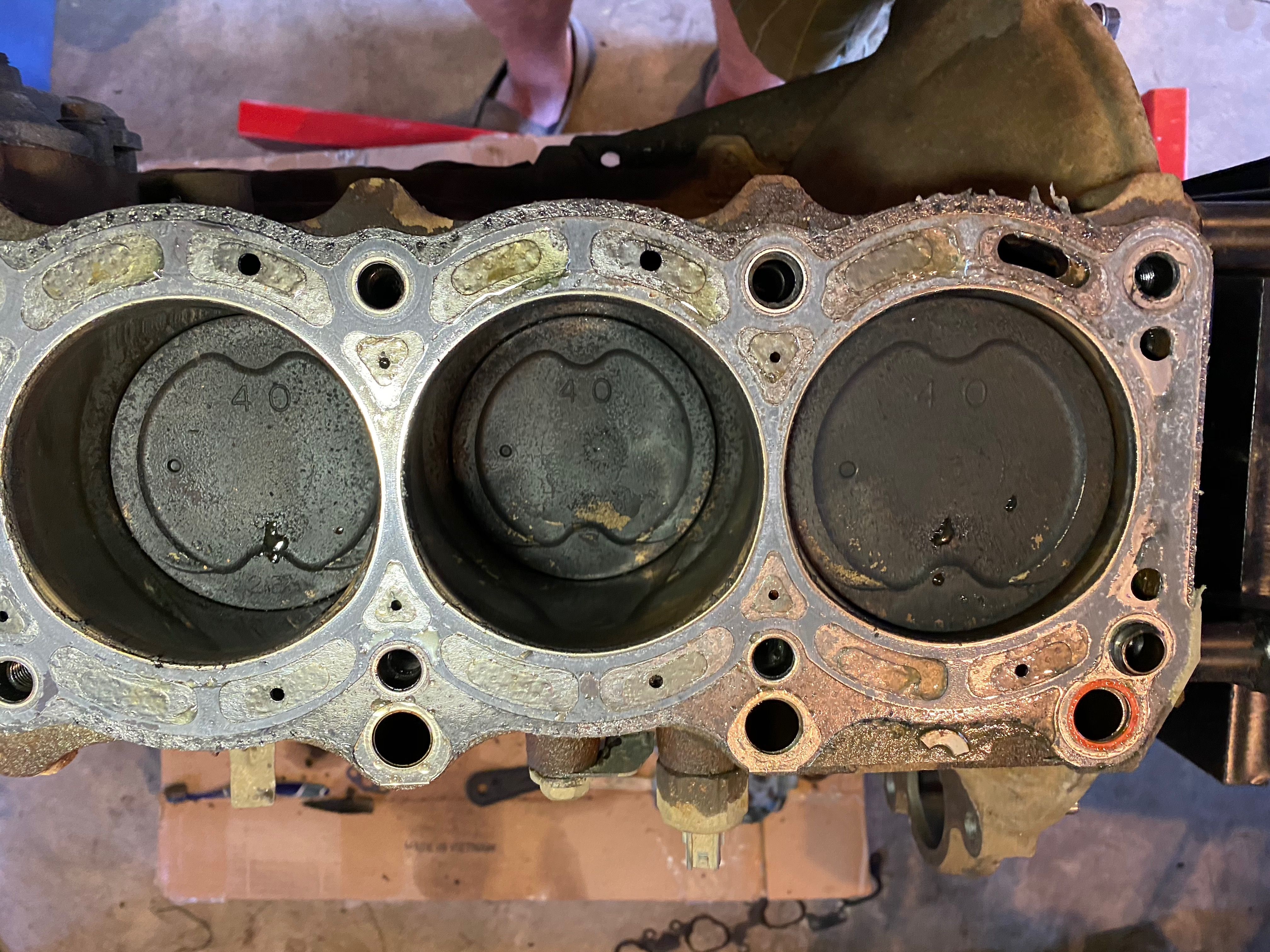

Worst piston

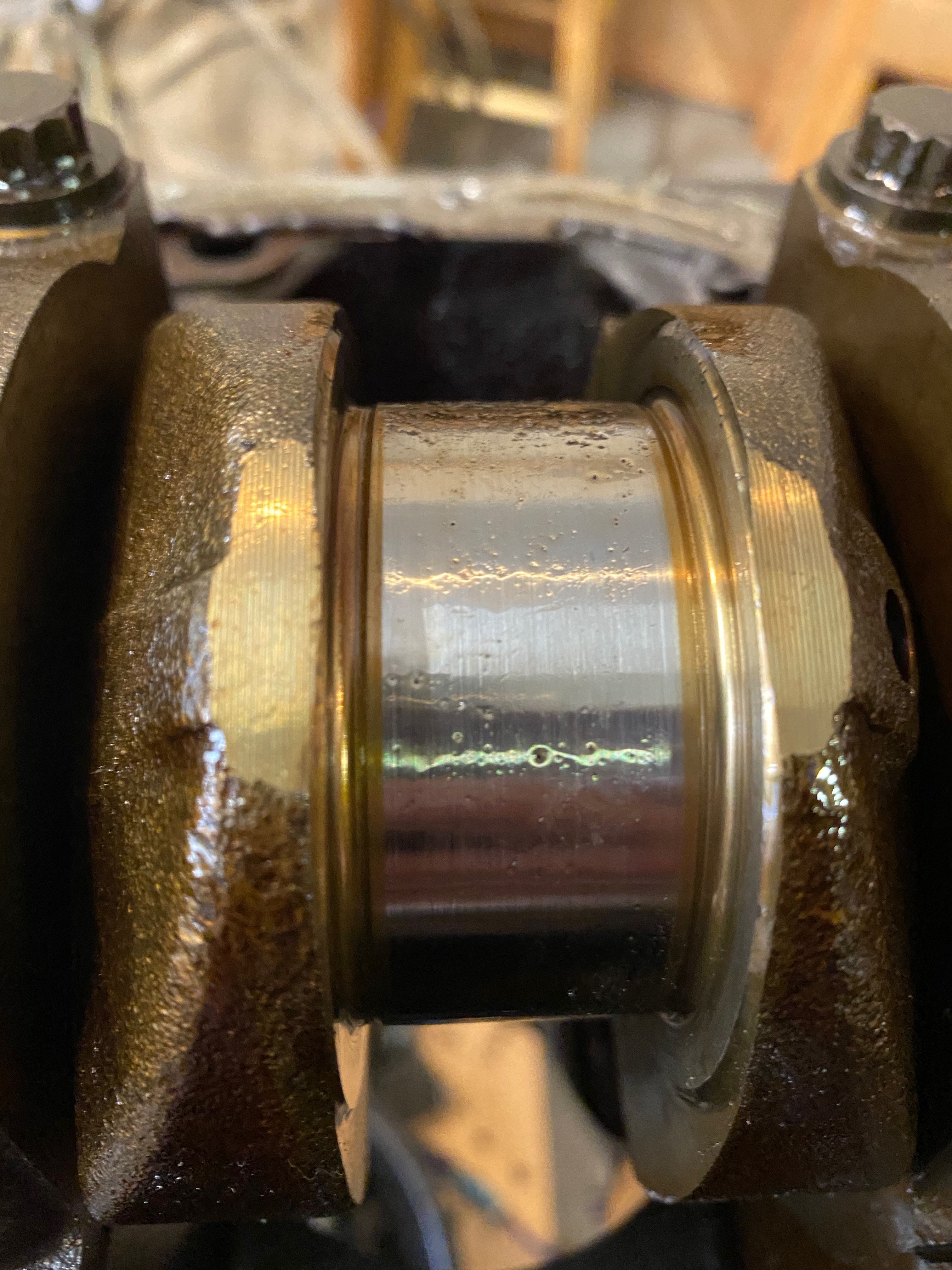

Good part of a journal on the crank for the connecting rod. Ignore the little bit of dirt that made its way on there as I pulled off the pan.

\

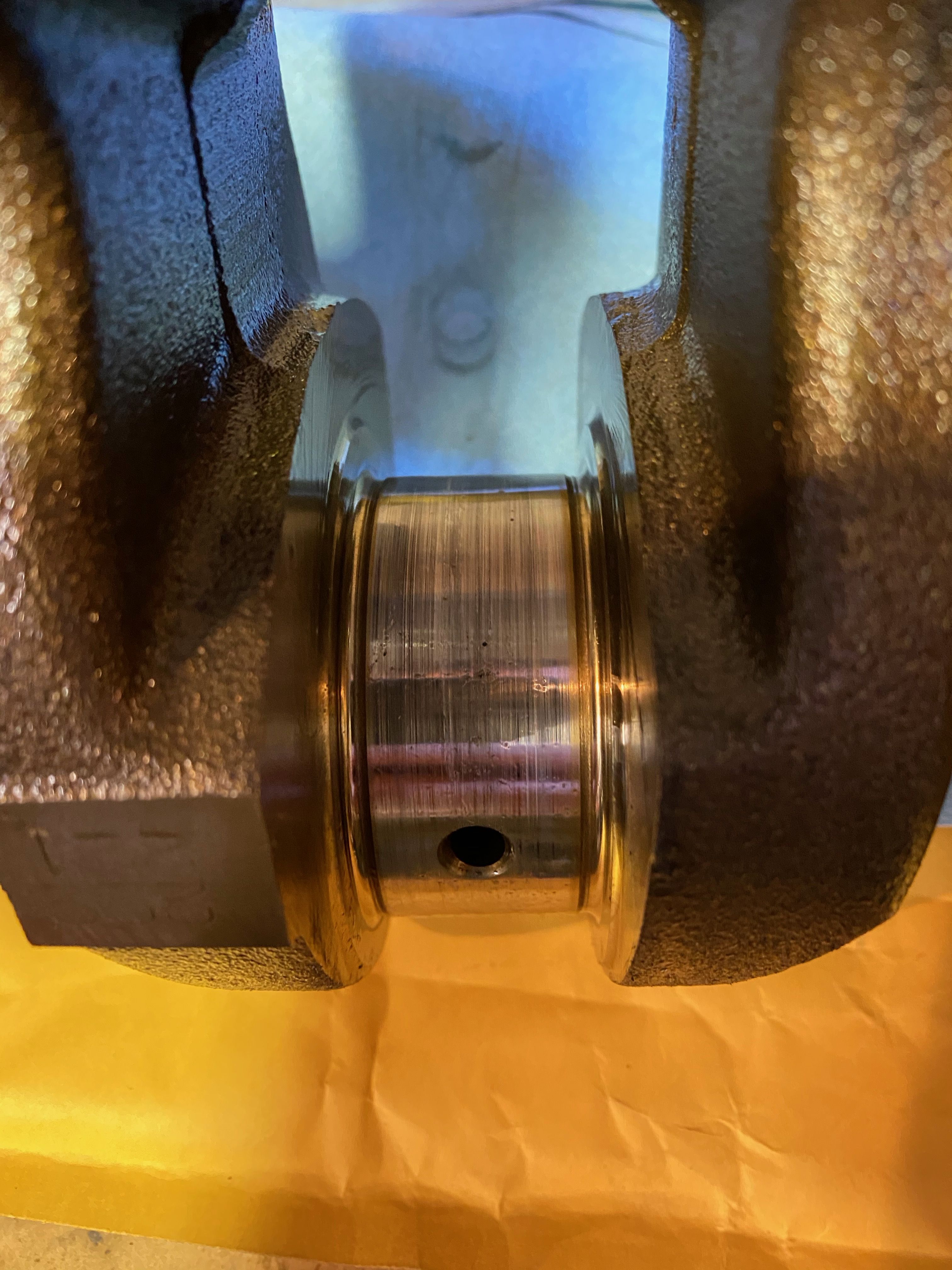

Worst part of the connecting rod journal on the crank.

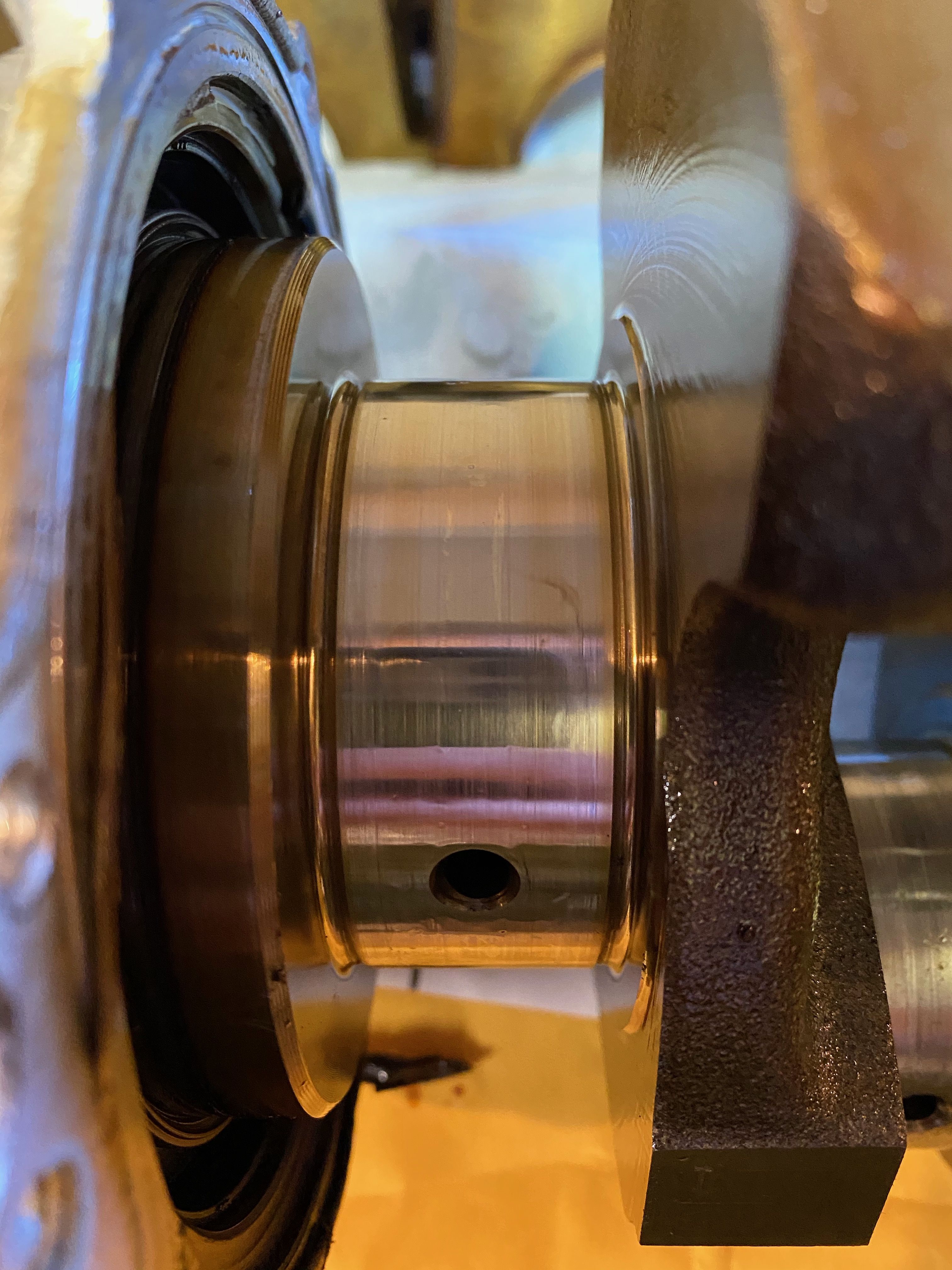

SHowing difference between good main journal and more worn rod journal

Another good main journal

Bad side of a rod journal

- Good thing I have new pistons and will be getting the cylinders bored out.

- The main bearings and thrust bearings look great, and so do the crankshaft journals for those.

- The connecting rod bearings are toast, though not disastrous. The journals on the crank for those look more damaged but not horribly so. Thinking that these may just polish out? Can't catch anything with a fingernail on these. None of these bearings seem to have spun. Most of the wear seems to be on the bottom part of the crank journal.

Not all that much in the strainer.

One of the worst connecting rod bearings (#1 & #6 were the worst)

Other side of the connecting rod bearing

Worst piston

Good part of a journal on the crank for the connecting rod. Ignore the little bit of dirt that made its way on there as I pulled off the pan.

\

Worst part of the connecting rod journal on the crank.

SHowing difference between good main journal and more worn rod journal

Another good main journal

Bad side of a rod journal

Last edited:

rover67

Rising Sun Member

You could get Andy's motor and pick the best from both to build one. I think he was planning on getting rid of it after various extremities were harvested.

dan1554

Rising Sun Member

Makes you wonder what got between the piston and cyl. wall.

My Crank is still available. I have not looked at it but should be better than that as it was never starved of oil. Cost of freight alone I'm sure will not be cheap due to weight. If a local option is available I'd look at that first.

And just a FYI main bearing availability from Toyota sucks. That is one place we had to go aftermarket as the size we needed was NLA. We used Clevite main bearings in my build.

And just a FYI main bearing availability from Toyota sucks. That is one place we had to go aftermarket as the size we needed was NLA. We used Clevite main bearings in my build.

You could get Andy's motor and pick the best from both to build one. I think he was planning on getting rid of it after various extremities were harvested.

Unfortunately I'm now in Bend OR so not easy to go grab some bits.

Makes you wonder what got between the piston and cyl. wall.

I'd imagine that maybe the bearing went and created some play in the connecting rod, then the piston just started wiggling around in the bore and hitting the wall

My Crank is still available. I have not looked at it but should be better than that as it was never starved of oil. Cost of freight alone I'm sure will not be cheap due to weight. If a local option is available I'd look at that first.

And just a FYI main bearing availability from Toyota sucks. That is one place we had to go aftermarket as the size we needed was NLA. We used Clevite main bearings in my build.

Thanks for the offer! Fedex seems to think it would be in the 100-150 range to ship. I imagine that the crank work in terms of polish or grind would probably be in the few hundred dollars range. I think when I drop the block tomorrow I'll take the crank and see what the machinist thinks and the cost. If he thinks super quick to just polish maybe go that route but if it takes a full grind and polish I'm leaning towards using your crank.

I did some poking around and looks like I can still get all the sizes of Toyo bearings online including the undersized set. Seems like the mark 2-6 vary in thickness by 1/1000" for each mark. So, given that I am running at a #4 on 5 of the rod bearings and #3 on the other, I have some wiggle room to go thicker about 2/1000's if they can keep the polishing in that range. Otherwise its .25mm undersized and a grind.

Suppose I could also see if my mirometer would fit on the journal as well to see if they are ovalized or not.

If nothing else I'm learning a bit about all this and spending lots of time on toyodiy/FSM/amayama/partsouq

On a related note anyone have experience with the Cams in the head looking that rough? I realize less force on those but they look fairly rough. I'm now kinda worried that I may be in for a new head if the cams are worn that bad to replace them and then the labor...seems like maybe a new head is possibly worth the extra cost?

Thank you all for your input! Very much appreciated!

Last edited:

Totally different question, regardless of which crank I use, do I need to get the spinny-bits ballanced? When they balance a crankshaft is that the crankshaft alone or do they in some way do that in the engine with pistons attached to account for that weight? Or given I'm using toyota parts do I just slap it all together with the right bearings and not worry about balancing anything?

Seems like with the slightly oversized pistons that the bob weight may change...but not sure how much of a deal that is for an I6 ? Something folks worry about when rebuilding these or not overthink it and bolt it back together?

Seems like with the slightly oversized pistons that the bob weight may change...but not sure how much of a deal that is for an I6 ? Something folks worry about when rebuilding these or not overthink it and bolt it back together?

Last edited:

We did not balance anything on mine. My builder indicated his experience building these engines did not warrant doing so. They are really good from the factory. He did weigh pistons and rods to be sure though.

Last edited:

My only constructive comment is those are some great pictures! Really educational, even for someone who's never torn an engine down.

Might try to hit up cruzer Dave aka Land Shark Outfitters, he's in Bend. He makes the KISS drawers, but knows a lot of folks around and may be able to point you to an 80 guy, or hoarder, etc.

Might try to hit up cruzer Dave aka Land Shark Outfitters, he's in Bend. He makes the KISS drawers, but knows a lot of folks around and may be able to point you to an 80 guy, or hoarder, etc.

rover67

Rising Sun Member

I think your best bet is to box it all up once taken apart and take it to the machine shop. Take it to a good one. let them tell you what they think they can clean up and what they can't. Give them the pistons to fit the bores. Me personally, I think those cams might work but I might be looking for used replacements. The head seems good, I probably wouldn't touch it. Curious how trashed the oil pump is and why it failed. One thing is for sure that motor was oil starved.

Too bad you aren't in the denver area, there are a few motors with parts to choose from...

I mean maybe you could get the cams from Andy's motor, those would be easy to ship if they looked good. His motor dies a similar death though.

Then it's down to the block and crank and rods. The crank does look like it'd take a polish an the machine shop could guide you on that easily I'd think. The rods who knows, I'd get them checked and caps cut and machined if needed. They might be fine tho. The block you'll know when the machine shop goes to clean it up if your pistons will cover the machine work that needs to happen.

I wouldn't shy away from Clevite bearings if OEM ones were a pain to find but again that's just me.

Figure out why it oil starved, that pumps' gotta have issues.

Too bad you aren't in the denver area, there are a few motors with parts to choose from...

I mean maybe you could get the cams from Andy's motor, those would be easy to ship if they looked good. His motor dies a similar death though.

Then it's down to the block and crank and rods. The crank does look like it'd take a polish an the machine shop could guide you on that easily I'd think. The rods who knows, I'd get them checked and caps cut and machined if needed. They might be fine tho. The block you'll know when the machine shop goes to clean it up if your pistons will cover the machine work that needs to happen.

I wouldn't shy away from Clevite bearings if OEM ones were a pain to find but again that's just me.

Figure out why it oil starved, that pumps' gotta have issues.

My only constructive comment is those are some great pictures! Really educational, even for someone who's never torn an engine down.

Might try to hit up cruzer Dave aka Land Shark Outfitters, he's in Bend. He makes the KISS drawers, but knows a lot of folks around and may be able to point you to an 80 guy, or hoarder, etc.

Thank you! I've taken a ton of pictures; with two purposes in doing so. 1.) If I end up with the time I want to do a newbie engine rebuild thread on Mud. So many of the rebuild threads are done by folks with tons of knowledge in general rebuilding so finding some of the newbie knowledge has been somewhat difficult. and 2.) to see how to put everything back together

I'll totally reach out to Dave and see if he's got any pointers/parts!\. I had contacted the Toyota club here in Bend but could not attend any meetings before Corona hit. I was able to get a lead to where most folks go for machine work here (there's not a lot of choices) so everyone seems to use the napa machine shop.

I think your best bet is to box it all up once taken apart and take it to the machine shop. Take it to a good one. let them tell you what they think they can clean up and what they can't. Give them the pistons to fit the bores. Me personally, I think those cams might work but I might be looking for used replacements. The head seems good, I probably wouldn't touch it. Curious how trashed the oil pump is and why it failed. One thing is for sure that motor was oil starved.

Thank you for all the thoughts & Feedback!! Really appreciate it!

Cool thats a good idea. So far my list of things to take to machine shop is this; anything I'm missing?

- Block

- Timing chain cover in case they need to deck the block.

- New piston set and ring set. (these are +1)

- Instructions from the FSM on sizing bore/etc.

- Crank

Totally. If I can find some specs on the journals and the cams still avail I may still go that route. Honestly the head/valves/etc scare me more than the lower end. :|rover67 said:Too bad you aren't in the denver area, there are a few motors with parts to choose from..

I mean maybe you could get the cams from Andy's motor, those would be easy to ship if they looked good. His motor dies a similar death though..

rover67 said:Then it's down to the block and crank and rods. The crank does look like it'd take a polish an the machine shop could guide you on that easily I'd think. The rods who knows, I'd get them checked and caps cut and machined if needed. They might be fine tho. The block you'll know when the machine shop goes to clean it up if your pistons will cover the machine work that needs to happen..

Sounds like I should take the rods in to the machine shop as well? I gather I should also try to find some wear specs on the crank end of the rod itself? I'm hoping that since nothing spun there is no appreciable wear and that I can just toss bearings in there. (adjusting for size based on how much material the polishing (or machining) takes off.

Thanks! I will keep that in mind; so far I was able to trace back a number of part superceedments (if thats a word) and all bearing marks seem to be in stock and available (post another week or so when they can ship from UAE). Not necessarily a purist to a large extent but I like the fact that being new to this I can use the FSM to see all the sizes of the Toyota bearings, what size I started, etc. I'd be worried that I'd mess something up if I went aftermarket by not having the right size or something.rover67 said:I wouldn't shy away from Clevite bearings if OEM ones were a pain to find but again that's just me.

At this rate I am 99% convinced it was a problem with the oil filter and only that. I need to do more research into how the high pressure bypass and the oil pathways in the engine work, but with my test of replacing just the filter and watching the pressure go normal...and other folks having done the same thing...I think for me safe to say that the bad filter killed the engine. Here's a few pics of the pump. Given that it hit 60psi on cold oil idle after the engine was roached, I think pump is still solid.rover67 said:Figure out why it oil starved, that pumps' gotta have issues.

Just for my (and other's reference) this pathway was posted on mud.

As I understand it the 1fz has only 2 relief valves (one at the pump and one at the oil cooler). The 3rd one referenced below I think is assumed to be on the filter itself.

It seems to indicate that there is no bypass around the filter. IE if Filter is not flowing oil and the filter's relief valve isn't functioning, the pump will build high pressure and then the pump relief valve will dump oil back into the pathway between the strainer and the pump.

So my thinking is the filter failed to flow sufficient oil...maybe stuck anti drain back valve or the filter relief valve? Then the oil pump worked fine and just kept pumping oil...but not to the filter...instead it bypassed right back to the circuit and everything filter and beyond got cooked.

I'm sure there is some good reasoning of not having the relief valve still flow to the engine...maybe they assume that the filter has its own (functioning) relief valve.

As I understand it the 1fz has only 2 relief valves (one at the pump and one at the oil cooler). The 3rd one referenced below I think is assumed to be on the filter itself.

It seems to indicate that there is no bypass around the filter. IE if Filter is not flowing oil and the filter's relief valve isn't functioning, the pump will build high pressure and then the pump relief valve will dump oil back into the pathway between the strainer and the pump.

So my thinking is the filter failed to flow sufficient oil...maybe stuck anti drain back valve or the filter relief valve? Then the oil pump worked fine and just kept pumping oil...but not to the filter...instead it bypassed right back to the circuit and everything filter and beyond got cooked.

I'm sure there is some good reasoning of not having the relief valve still flow to the engine...maybe they assume that the filter has its own (functioning) relief valve.

rover67

Rising Sun Member

Oh yeah I forgot about your oil filter test... that pump looks nice.

the rods typically the check is for roundness on the big end, if it's not round they machine the caps a bit so they make more of an oblong hole and not a round one, then the re machine a new round hole to factory specs. They also check for twist and straightness. If the big end bearings get beat up and allow the rod to slam back and forth that big end can be hammered into a non-round shape. That being said yours don't looks that bad so maybe no need to take them in. I'm guessing it wouldn't cost much to have them check the rods at a minimum tho.

the rods typically the check is for roundness on the big end, if it's not round they machine the caps a bit so they make more of an oblong hole and not a round one, then the re machine a new round hole to factory specs. They also check for twist and straightness. If the big end bearings get beat up and allow the rod to slam back and forth that big end can be hammered into a non-round shape. That being said yours don't looks that bad so maybe no need to take them in. I'm guessing it wouldn't cost much to have them check the rods at a minimum tho.

Oh yeah I forgot about your oil filter test... that pump looks nice.

the rods typically the check is for roundness on the big end, if it's not round they machine the caps a bit so they make more of an oblong hole and not a round one, then the re machine a new round hole to factory specs. They also check for twist and straightness. If the big end bearings get beat up and allow the rod to slam back and forth that big end can be hammered into a non-round shape. That being said yours don't looks that bad so maybe no need to take them in. I'm guessing it wouldn't cost much to have them check the rods at a minimum tho.

Perfect! Thanks that explanation really helps. I'll take them in as well when I go.

rover67

Rising Sun Member

If the wrist pins are a press fit into the small ends of the rods they can also install the pistons for you after checking/machining everything. I'm not sure how the wrist pin is held in on a 1FZ (some are clips in the piston for example)