DaveInDenver

Rising Sun Ham Guru

When looking for those MIL A52425 terminals consider making sure you get the lead ones.

They make them in zinc (e.g. so they're lead-free, which is required in some cases for RoHS) but those didn't hold up over time for me and eventually cracked. They are probably OK if you install and forget, though.

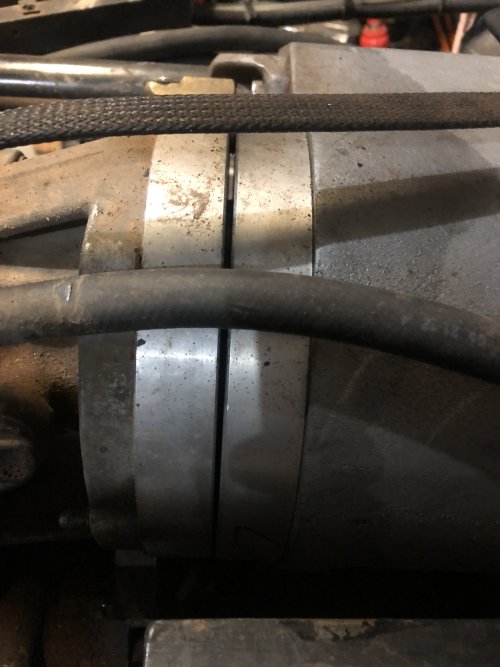

And a FWIW, I prefer the ordnance style personally. These particular ones are made by East Penn (the battery company). The sets I got were very high quality, the casting was very clean.

They make them in zinc (e.g. so they're lead-free, which is required in some cases for RoHS) but those didn't hold up over time for me and eventually cracked. They are probably OK if you install and forget, though.

And a FWIW, I prefer the ordnance style personally. These particular ones are made by East Penn (the battery company). The sets I got were very high quality, the casting was very clean.

Ordnance Bolt Type Battery Terminal - Universal - WiringProducts, Ltd.

Ordnance Bolt Type Battery Terminal Long bolt (5/16") allow for additional power connection. Designed with a metallic lead alloy for maximum performance. Rated up to 48V DC. Type: Universal. Material: Lead Construction.

www.wiringproducts.com

Last edited: