Not saying I am going this way. Many of the reviews I watched like these pulleys and say the rope falling out isn't a problem. They do agree that they are less efficient, but not really an issue like you said. I watched several from Australia who have a pretty good following.There’s a lot to unpack here, but a note that Corbet made about traditional pulley blocks had me go back and check your link.

@Romer please please please please please please do not buy one of those death bagel items claimed to be better than pulley blocks (colloquially called “snatch blocks” and because Australians like to use that word for recoveries) for winching. They are a solution looking for a problem. Their most dangerous aspect, addressed with the totally disingenuous title of “rope retention pulley”, is the rope falling out of the groove under slack conditions, which it will do, and those little plastic fingers make it worse. When the rope falls out of the groove you get rope on rope and when you start winching again, having failed to notice that it fell out, you will instantly cut one of the lines. And don’t just say well I can put it back in the groove because sometimes when you’re winching, you’re in situations where it’s impossible to take tension off the rope because you are on the winch.

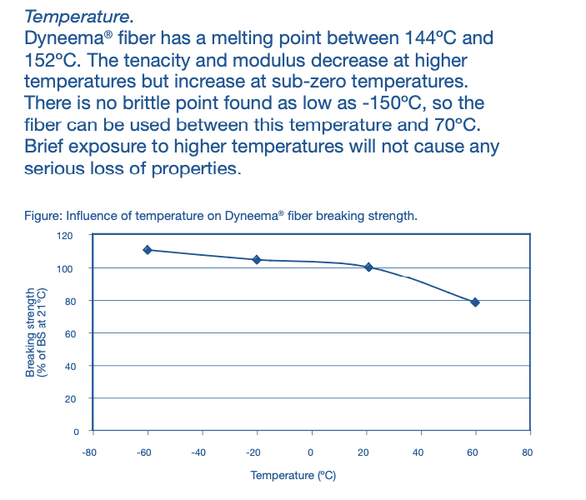

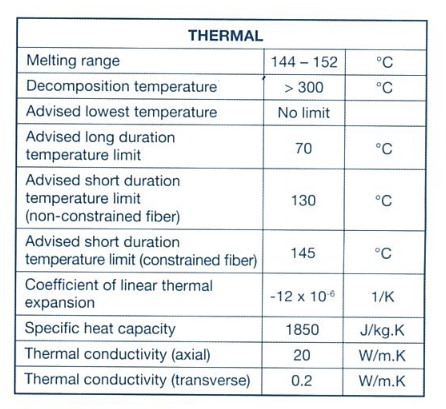

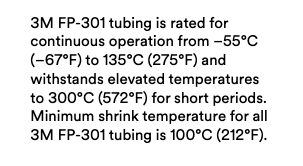

Second is that they increase friction, friction is one of the top enemies of synthetic because friction causes heat. There is a slight loss of efficiency, but that’s less important.

I am wondering if your position is based on actual use and data or an opinion based on how it is constructed.