I'm not sure there's a definitive answer here. It looks good for sure.

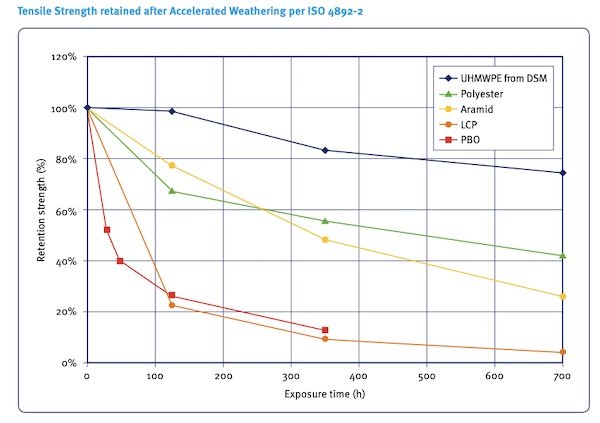

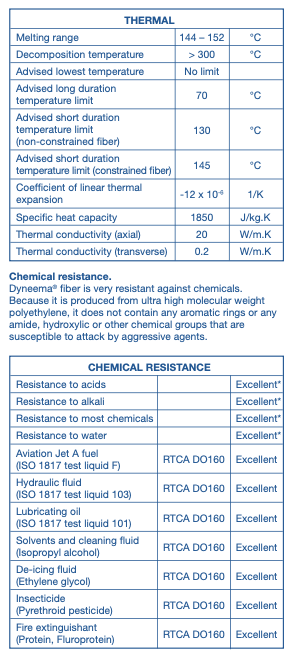

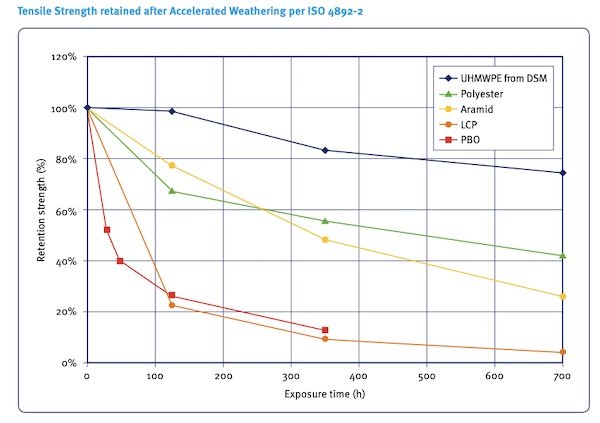

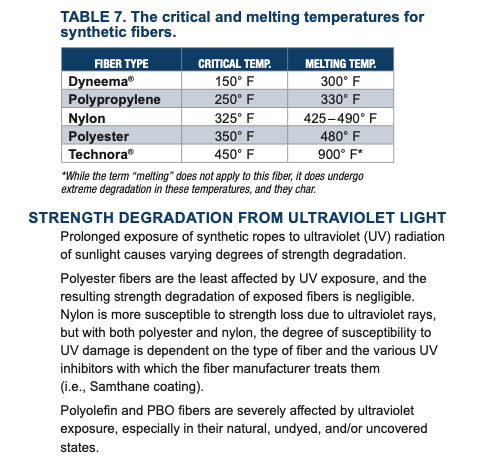

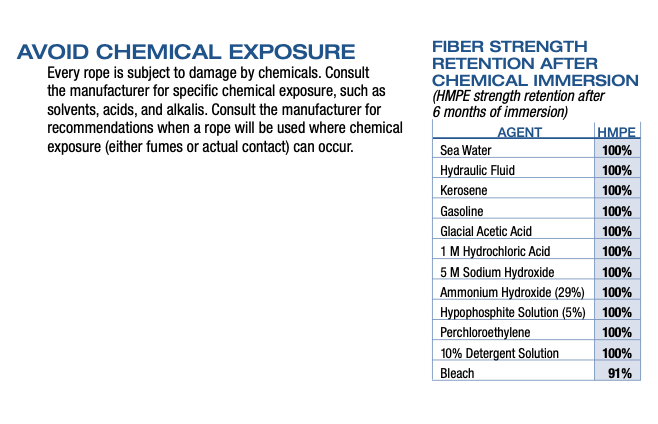

Thinking points I suppose might be to consider what problems you're trying to solve. Dyneema is not highly UV sensitive, but neither is it zero. Dyneema is woven from UHMWPE fibers and as a result is also highly chemical resistant. What rapidly degrades it is heat.

So take all the factors and stew them I think the trade-off question is whether the protection from UV is offset by what is essentially a blanket holding in heat. I'd make it light colored to reflect as much sunlight as possible for that.

A wrap isn't really needed to protect the rope from road salt or debris. Any moisture will also be held inside which could encourage mildew. But that's not going to hurt the rope. What I'd worry most here is holding moisture that encourages the drum to rust under the rope.

In my mind the greatest benefit to this is to prevent mechanical damage such as tools and parts being dropped on the rope.

My concern would be how warm it would get under there in the sun and close to the radiator. Dyneema should be kept below 70°C/158°F in long term storage but that number is not absolute go/no-go, generally the less heat you subject the rope to the better.

Another reason to wrap a winch line may be to prevent it snagging someone but that's not a problem with synthetic. There's nothing rough or poking out that will cut your hands.

You know, though, what came to my mind is whether a wrap on the drum like this might offer benefit. Insulating the first wrap from heat of the brake and motor could be useful. It would introduce a variable of getting that first wrap good and tight on the drum, which could easily negate any thermal benefit so I don't know if there's a practical solution there.

All in all I'm not sure it would solve a problem I have but I also don't think it's really hurting anything. Kind of seems to fall into the category of where to use abrasion sleeves. On one hand those prevent cuts but they also trap debris that can wear down the fibers, so neither 100% good or bad.