Good to know, my joints did look nice and shiny.

Per NASA-STD-8739.3, " Soldered Electrical Connections"

Wetting is the term used to describe solder movement and it's like it sounds, how it "wets" or flows. You're looking for the solder to easily turn from solid to liquid, flow smoothly into the joint and cool evenly.

Solder is a actually not simple topic but suffice to say it generally refers to using an alloy of lead, zinc, tin or/and other elements to make a substance that melts onto the base material, in this case copper. It's not welding, where the base material is actually molten but is hot enough to make the solder become essentially a metal glue that grabs the copper at the molecular level. It's the same as brazing. Copper melts at 1,073°C while most solder becomes liquid at about 300°C to 400°C. It's technically going from solid to liquid and refreezing into a solid, but it's a bit more complicated due to the alloy needing all it's component elements to do so at the same temperature going up and down, so there's some black magic that happens in finding the right ratios that don't end up with debris or cracking or other failures.

The key is the solder has to flow in and all around the copper at an atomic level. It's a permanent modification of the wire, e.g. when you "tin" the wire the solder will have flowed into the copper to the point that you will never be able to remove it all. It's like if you dye your clothes (or wash your white socks with a forgotten red shop rag). You can wash and wash and wash and only make the socks fainter pink but never white again.

To make it even more confusing is you add a flux to assist in the wetting and cleaning. Once a copper wire is made it begins to oxidize immediately. Sometimes the manufacturer will tin the wire as they make it, in which case it's already got a base coat of solder. Often they will not. In this case the flux when you heat it re-exposes the copper to help the solder adhere at a molecular level.

The whole process is patting your head, rubbing your belly to get right. You touch the iron to the joint, it heats rapidly but not to the point of damaging the wire or something else (melt a ton of insulation, for example, or making the flux into charcoal), then you touch the solder, it flows sufficiently, you remove the solder feed and iron and it cools quickly but not too quick into a smooth joint. There's about a thousand ways to go sideways.

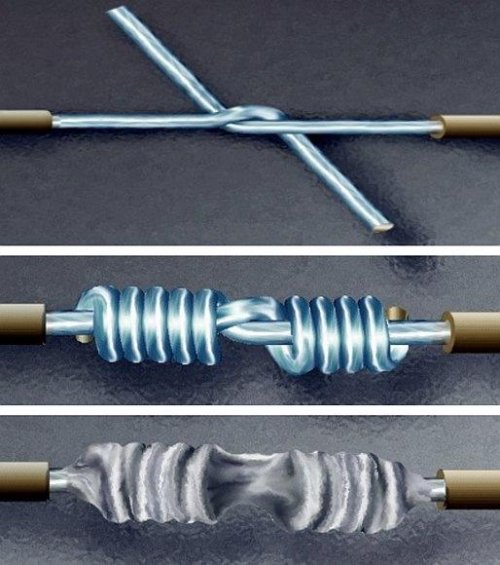

In any case, this is an extreme example of not having enough heat resulting in a cold joint. The joint never reached high enough temperature for the solder to fully bond with the copper. The solder did melt a little but did not flow, e.g. wet, correctly. It might work but it's not a reliable joint for a lot of reasons.

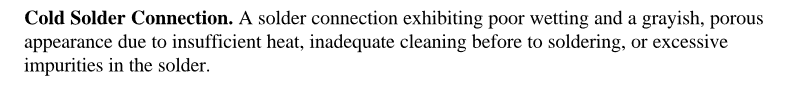

This is what happens when you have enough heat to completely solder the copper conductors.

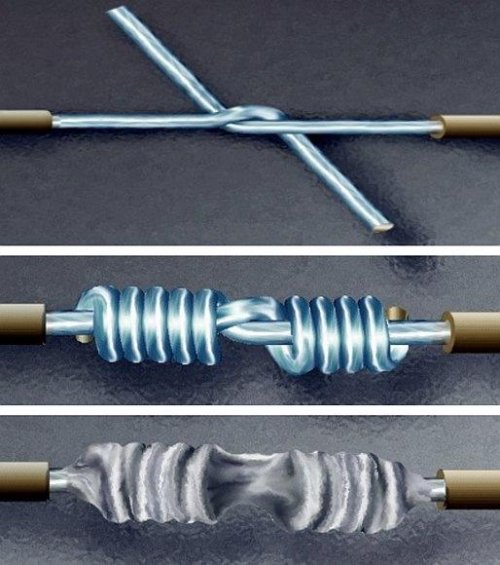

As an additional point no one cares about, there's actually a preferred (or in aerospace, "right") way to make a butt splice by twisting two wires and soldering for reliability.