Based on the responses since last night, I must have left a few things out along the way or not been very good at communicating my thoughts. I haven't fully had it running yet. When I picked it up, it hadn't really been run in several years and had been mostly disassembled for some shade tree body work. You guys are absolutely right that there are things more important to the overall running condition of the truck than carburetor jetting, and you'll not hear me argue otherwise. That said, a properly tuned carb is about as important as a properly set distributor in my book.

You may notice that I haven't actually done any carb tuning yet because I haven't done all of the things you collectively described above yet. The lack of power was due in no small part to retarded timing, and I expect to find at least one tight exhaust valve. I think I fixed my vacuum leak, but my fuel pump died while I was tracking it down so I had to stop and fix that (my fuel system save the hard lines is now completely new or rebuilt)... Then my coil died before I could make sure it was totally rectified (ignition system will be nearly to the same level as the fuel system)... Now I have to wait until the end of next week to install that (the seller was out of stock without realizing it, and Pertronix had to MAKE one).

The current order of operation is as follows:

- Figure out why the transfer case shifter won't come out of four wheel drive

-- Rectify

- Install new ignition setup

-- Set timing

-- Check to make sure everything else is in spec (mainly dwell since the rest probably won't spec out right being aftermarket...)

- Make sure the vacuum leak is, in fact, fully rectified

-- If not, I think the next culpable part is the vacuum check valve boot, so I'll have to order one of those little bastards

- Warm it up and adjust the valves (the new gasket is sitting on my coffee table)

- Baseline the carb

-- Factory jetting

-- Idle mixture

-- Idle speed

- Drive the truck up to where I can reach it with electricity so I can drill out the sheared bolts and install the bezel, windshield washer system, and DS jump seat

- Inspection, registration

- Tires

-- See if I can swap the spare aftermarket wheel out at Jim's for one that fully matches first

- Windshield

- Windshield wipers

-

Tune carb

-- Check and record performance of factory sea level jets

-- Ditto factory altitude jets

-- Fine tune old school (unless I can get my hands on a wide band setup in the meantime)

-- Document for posterity

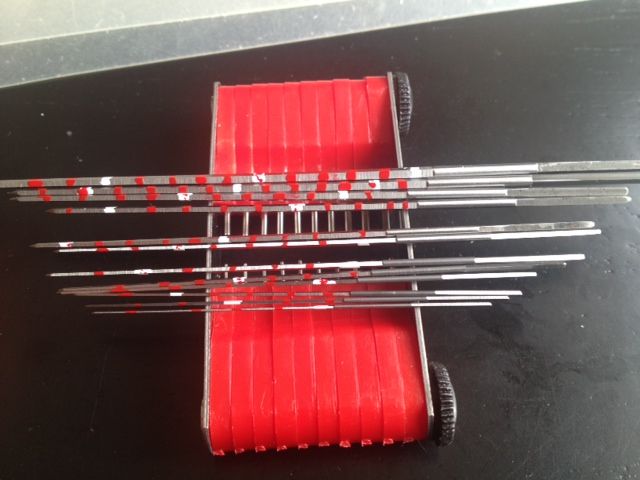

You'll note that fine tuning the carb is at the very end of everything. Mic'ing out reams and tracking down jets is a great way to feel like I'm doing something while I'm waiting for other parts to come in, and clearly something that isn't widely known in the TLC universe. If you discount my wife's car, this is my newest car out of three by more than a decade and a half (and a few years later than what I generally entertain) and I will undoubtedly go through many more in the coming years, so the reams and gauges aren't solely for this project. I bought a set corresponding to this project because jets for these carbs are NLA and doing so is cheaper than the plane ticket that would be required to utilize the set I would have in the past. I still need to get another pin vise (ordered last night) and a bunch of ultra fine drill bits to be able to plug and ream what I have (which I intend to write up for those interested). The 70 power jet I just received has been punched out to an 80, so I'll close it up and ream it to a true 70 for tutorial purposes.

I come from a different end of the automotive hobby. As I've said in the past, aircooled cars are very sensitive to tune. You'll never hear someone bragging about setting their timing by ear because they will have burned up their engine as a result and have to rebuild. Run too lean: 5hp may not seem like much until you only have 50 to start with, valves burn very fast, cylinders melt, studs pull, flanges warp... welcome to rebuild town. Run too rich: (same general concept as running too lean), rebuild. Too much timing: you get the idea. If you drive an aircooled car, you learn to hear what your engine is telling you. You either must learn to do all your own work (which is more fun anyway), or you must have an enormous bank account (especially for the Porsches) and incredible patience. Cars are like women: aircooled cars are beautiful, complex, and a little high maintenance, but if you take care of them they'll take care of you. These trucks are nowhere near as needy, but they definitely enjoy the attention all the same.

Others of my hobbies include watchmaking and luthiery (which may explain some of my automotive eccentricities). I can hear the differences in how a guitar is built and what it is made of from a single strummed chord. Those tonal nuances are just as apparent in a car's engine. I can hear when something is off and I can hear when it's just right (and it bugs the crap out of me when it's not). When I was out shopping for cars, I found a guy's exhaust leak (missing exhaust manifold stud on the rearmost DS cylinder) on his V8 by sound after driving the truck for less than a quarter mile. We pulled over, lifted the hood, and there it was (or rather wasn't). Assuming everything else is dialed in, there is an acute tonal difference between a properly tuned carb (sharper, more staccato, and with more defined higher order harmonics) and one that's off on either end (duller, muddier, less defined; I'm guessing it has to do with the smoothness and/or completeness of the burn, maybe the speed of it?). There are other things that hint at other maladies, but this is getting way off into weirdo land... Maybe I'll make more sense if/when you meet me in person.