No experience with them. Everyone I know that runs them, really like them.The M/T I'm considering is the Yokohama Geolandar M/T G003. They're the highest rated in every category.

There was a member in a minitruck for the snow run - red with a tube steel bed - and I briefly spoke with him about them. He was happy with their performance and road noise, but had only run them for about 5k if I remember correctly.

Anyone else running these that can speak to their performance?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tire talk

- Thread starter DomOfTheDead

- Start date

HalfBreed

Lifted

That was my dad in the mini you talked with. They work well on that truck, but it has been a crawler with little daily driver duties.The M/T I'm considering is the Yokohama Geolandar M/T G003. They're the highest rated in every category.

There was a member in a minitruck for the snow run - red with a tube steel bed - and I briefly spoke with him about them. He was happy with their performance and road noise, but had only run them for about 5k if I remember correctly.

Anyone else running these that can speak to their performance?

We have another set on a 3rd gen 4runner, tires have about 1/3 tread life and are a bit sketchy in slick conditions.

Oh, yah they suck in snow just like ALL mt’s. I’ve always had a 2nd set of wheels/tires for the winter. If you’re looking for one set of tires year round then buy all terrain's.

Inukshuk

Rising Sun Member

Contrary to Dave’s comment above, I am of the school of thought that mud terrains are worse in loose sand. And I’ve driven a lot of sand from Wyoming to Jordan and Baja.

I’ve always run all terrain’s and my current A. of choice is the Kenda Klever AT/2. I have the RT on long cruiser and they do just fine also looking more aggressive.

My daily driver has the Geolander G015 which can do light all terrain duty, and love that tire.

I’ve always run all terrain’s and my current A. of choice is the Kenda Klever AT/2. I have the RT on long cruiser and they do just fine also looking more aggressive.

My daily driver has the Geolander G015 which can do light all terrain duty, and love that tire.

I just grabbed some Kanati Mud Hog 35's! Finally...pics soon! Also tried some Pirelli Scorpions on Connor's 4runner.

FYI Zac at Nomad will give 10% off anything on his site to Rising Sun folks: https://www.nomadcruisers.com/

code is RISE4X4

He can also get tires at decent prices. Good guy! He is doing some work on my 40 down in Cripple Creek.

https://www.nomadcruisers.com/.../35x10-50r15lt-kanati.../58

"We have a new selection of tires we can drop ship to your door!

Use code SPRING25 to get 5% off your order"

FYI Zac at Nomad will give 10% off anything on his site to Rising Sun folks: https://www.nomadcruisers.com/

code is RISE4X4

He can also get tires at decent prices. Good guy! He is doing some work on my 40 down in Cripple Creek.

https://www.nomadcruisers.com/.../35x10-50r15lt-kanati.../58

"We have a new selection of tires we can drop ship to your door!

Use code SPRING25 to get 5% off your order"

allen.wrench

Rising Sun Member

Beaver Teef Flap Jackers because they bite well and slap the mud

does it go well with??

liver and fava beans!

Allen

All these new tire names…”I run the Beaver Teef Flap Jackers because they bite well and slap the mud!”

I can’t run any of them with 15’s Maybe the Kenda otherwise tried and true BFG it is.

I put the Kanati's on my 40 with 15s. Pics soon!

Next tire question...

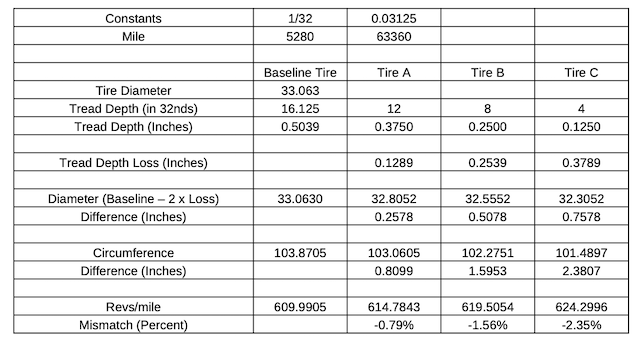

what % diameter difference do you consider allowable for an AWD vehicle? please answer quantitatively.

consider this scenario- a year ago I buy 5 new tires, 255 80 r17. that maths out to 33.063" This past weekend I take a nail to a sidewall... patch it, drive home, go to Discount and cash in my warranty cert, drive home today with a new tire. Guy at the counter suggests running the new one as a spare only, since those others are now worn down. I've been rotating 5 tires. I've never completely bought into the idea that all 4 tires must exactly be the same, if that were the case then how could I get away with turning corners right? I have 3 differentials for pete's sake, and they have a purpose.

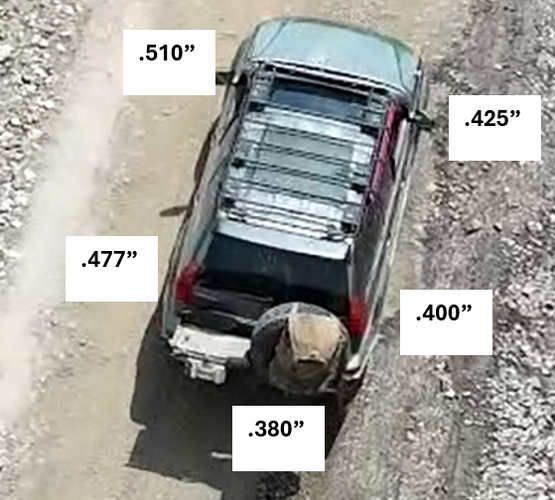

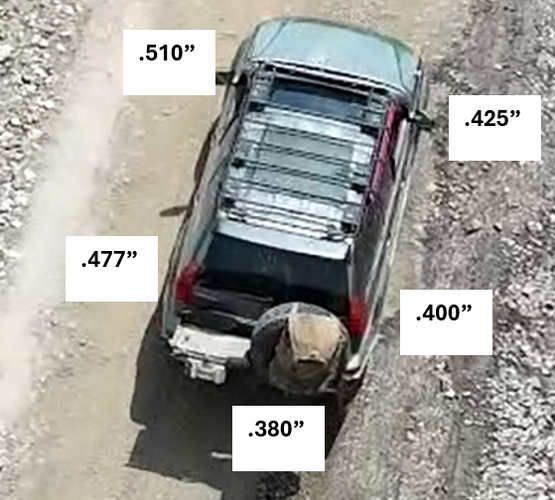

I measure my newest tire tread depth at .505". I measure my other 4 tires, the current spare that would go back to LF at the next rotation is at .460" tread depth. The most worn tire is currently at .420", which is .085" less than the new one. But all 5 tires within .100" of each other.

What I'm going to do is measure all 5 tires again, put my new tire in the LF, then rank order them thickest to thinnest LR, RF, RR, and Spare. That puts the most worn tire in the spare position, and the least worn tire (the new one) in the position where it's got 4 spots to go before it can be a spare again. And the other tires all fall in line in a position relative to their current tread depth. In a year the tread depth of all 5 should be less than what it is today, presuming all 4 locations wear evenly.

but of course the analytical side of me is thinking well this new tire is 33.063", and I have a worn tire that is 32.893" or 33.063-(.085*2) That is less than a 1% difference in diameter, which I consider totally within the acceptable range. but then I got to thinking, has it ever been established what is not acceptable?

what % diameter difference do you consider allowable for an AWD vehicle? please answer quantitatively.

what % diameter difference do you consider allowable for an AWD vehicle? please answer quantitatively.

consider this scenario- a year ago I buy 5 new tires, 255 80 r17. that maths out to 33.063" This past weekend I take a nail to a sidewall... patch it, drive home, go to Discount and cash in my warranty cert, drive home today with a new tire. Guy at the counter suggests running the new one as a spare only, since those others are now worn down. I've been rotating 5 tires. I've never completely bought into the idea that all 4 tires must exactly be the same, if that were the case then how could I get away with turning corners right? I have 3 differentials for pete's sake, and they have a purpose.

I measure my newest tire tread depth at .505". I measure my other 4 tires, the current spare that would go back to LF at the next rotation is at .460" tread depth. The most worn tire is currently at .420", which is .085" less than the new one. But all 5 tires within .100" of each other.

What I'm going to do is measure all 5 tires again, put my new tire in the LF, then rank order them thickest to thinnest LR, RF, RR, and Spare. That puts the most worn tire in the spare position, and the least worn tire (the new one) in the position where it's got 4 spots to go before it can be a spare again. And the other tires all fall in line in a position relative to their current tread depth. In a year the tread depth of all 5 should be less than what it is today, presuming all 4 locations wear evenly.

but of course the analytical side of me is thinking well this new tire is 33.063", and I have a worn tire that is 32.893" or 33.063-(.085*2) That is less than a 1% difference in diameter, which I consider totally within the acceptable range. but then I got to thinking, has it ever been established what is not acceptable?

what % diameter difference do you consider allowable for an AWD vehicle? please answer quantitatively.

I don’t have a specific % to post but approve your plan. It’s what I would do if it were my truck.

If all your tires were worn much more I’d say save the new tire as the spare and then just buy 4 tires in a year when you needed them.

If all your tires were worn much more I’d say save the new tire as the spare and then just buy 4 tires in a year when you needed them.

Ah, see? why can't you quantify "much more?" exactly how much more?I don’t have a specific % to post but approve your plan. It’s what I would do if it were my truck.

If all your tires were worn much more I’d say save the new tire as the spare and then just buy 4 tires in a year when you needed them.

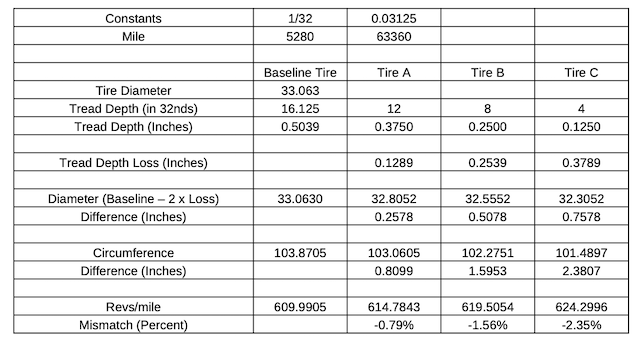

I think most tire shops and DOT agree that 4/32" tread depth is when you replace a tire, regardless of age, for stopping distance reasons. If I had a tire at 4/32 that's .125" of tread.. which means I would have worn off .380" of tread (.505-.125). Safe to assume you wouldn't run a brand new tire and a worn out tire at the same time, right? 33.063-.380-.380=32.303/33.063=.977 or 2.3% diameter deviation.

So 1% is acceptable, 2.3% is too much. maybe the upper limit is 1.5%... so in this instance a 32.567" diameter tire, equating to .496 total tread depth or .248" of tread depth per side. aka 8/32 per your thread gauge, or half the tread of a new tire.

So here's my current tread depth, by location:

LF is brand new, LR was put on as the spare initially then later did one shift of about 4000 miles. This set has about 9000 miles on it, with one rotation about midway. The other three each have worked 2 shifts to this point, as they've been on there the whole time.. if you're still with me, here are my takeaways..

- The range between existing tires, rotated normally, is greater than the range of a new vs. old tire. So blindly stating "don't mix old and new tires" is not only incorrect, it's based on poor (or no) data. I have almost a .100" difference in tread depth between two tires purchased on the same day.

- It looks like my tires wear about .030"-.040" every 5000 miles, or .000007" per mile. I'd be curious to see what other trucks do, how location-specific is it, etc. I might start tracking this closer in the future.

- It's worth the effort to get a gauge that measures tread depth. I could probably stand to upgrade from my caliper, but it's a tool I use quite often and I feel pretty good about my technique.. happy to discuss accuracy vs. precision and gauge repeatability vs. reproducibility any time.

I'll probably drive like this all winter, then rotate them again next spring before Cruise Moab. I'm sure you can't wait to see the data...

LF is brand new, LR was put on as the spare initially then later did one shift of about 4000 miles. This set has about 9000 miles on it, with one rotation about midway. The other three each have worked 2 shifts to this point, as they've been on there the whole time.. if you're still with me, here are my takeaways..

- The range between existing tires, rotated normally, is greater than the range of a new vs. old tire. So blindly stating "don't mix old and new tires" is not only incorrect, it's based on poor (or no) data. I have almost a .100" difference in tread depth between two tires purchased on the same day.

- It looks like my tires wear about .030"-.040" every 5000 miles, or .000007" per mile. I'd be curious to see what other trucks do, how location-specific is it, etc. I might start tracking this closer in the future.

- It's worth the effort to get a gauge that measures tread depth. I could probably stand to upgrade from my caliper, but it's a tool I use quite often and I feel pretty good about my technique.. happy to discuss accuracy vs. precision and gauge repeatability vs. reproducibility any time.

I'll probably drive like this all winter, then rotate them again next spring before Cruise Moab. I'm sure you can't wait to see the data...

DaveInDenver

Rising Sun Ham Guru

Alright @nakman, you wanted analytical.

But what does that tell us? I have no idea how much is acceptable. Obviously the differential is there to allow for tire size and speed mismatch, so you can turn and all that.

So I'd assume what you're worried about is heat from asking the differential to have a constant mismatch. When you go straight with perfect tires the two sides are turning at the same speed so the differential isn't differential'ing.

But when there is a mismatch the spider is slowly turning, building heat. I'd think mechanically that shouldn't be a problem as long as it's not excessive and you have enough lube in good shape. It's doing this all the time anyway, as you drift left and right, the road curves, normal air pressure differences, etc.

With an auto locker or limited slip excessive differences might be a more significant problem, that might be wearing couplers, friction packs, pins.

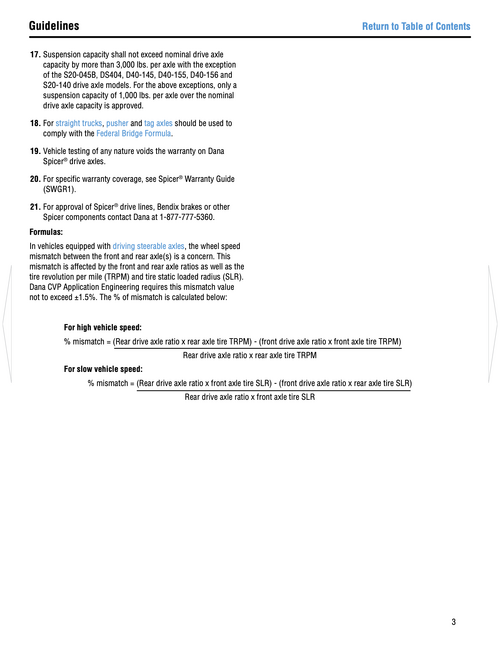

I couldn't find anything Toyota that says this but it's a commonly specified thing for commercial trucks. They variously seem to fall in the 1.5% mismatch as a maximum. If that is applied here then using a brand new slightly more than 16/32" should be matched with nothing more worn than 8/32".

My suspicion is that across a regular axle, no LSD or auto locker, that is conservative. OTOH if you have a LSD that is probably not a bad rule of thumb.

It's even harder to find recommendations for front-to-back when you have a transfer case. I found some references in 4WD tractors that suggest you want 0% mismatch up to a 5% forward bias (e.g. the front axle pulling rather than the rear axle pushing). That might be more about control than wear, I dunno. Then again I've always understood that new tires go on the back, not the front. So control again, e.g. under steer, not over rather than an axle wear issue?

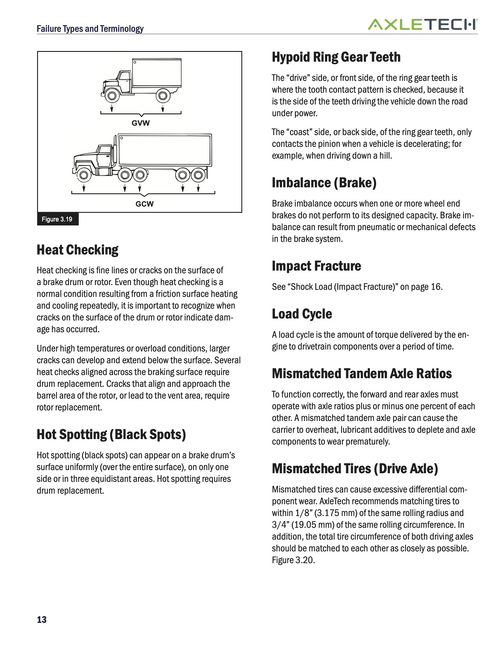

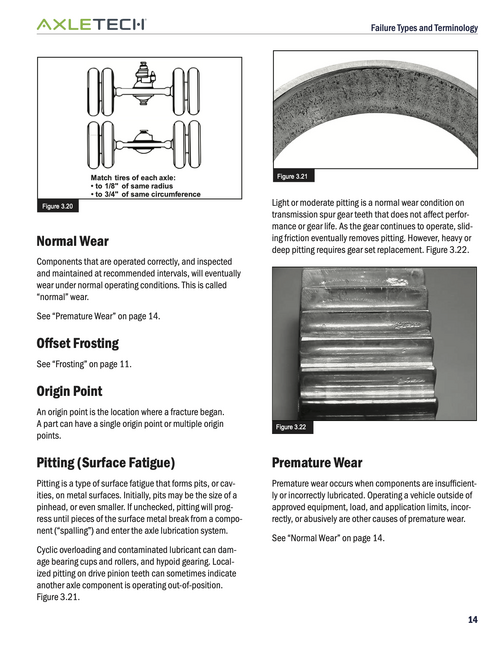

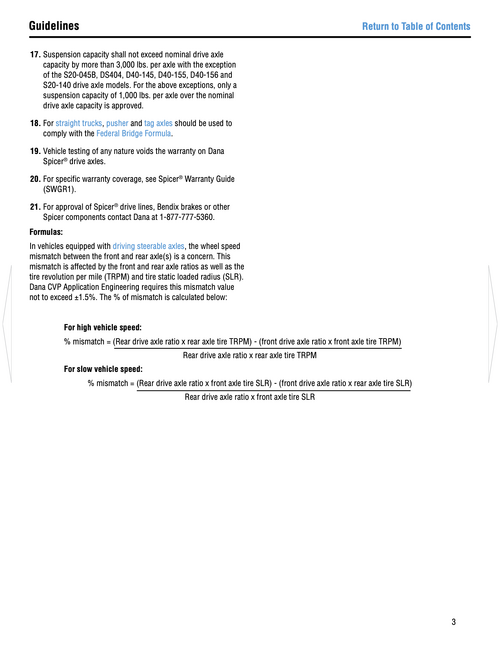

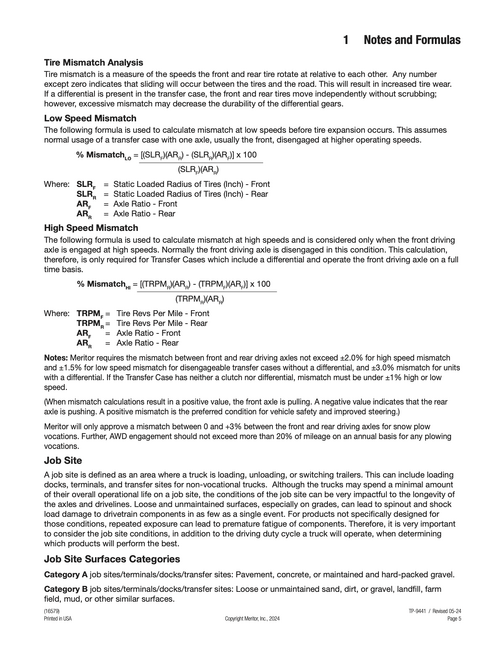

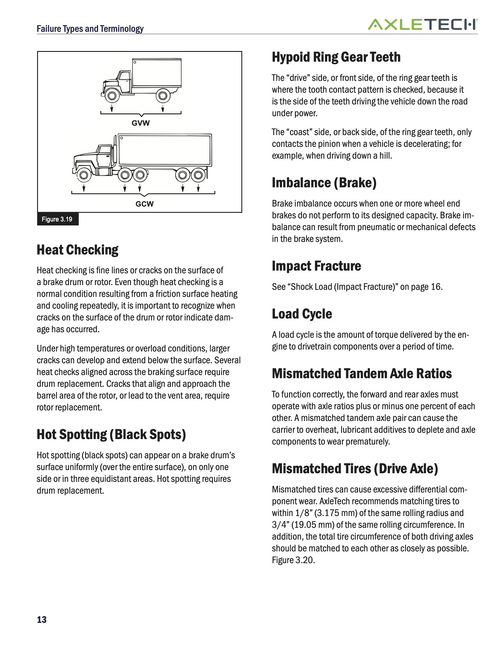

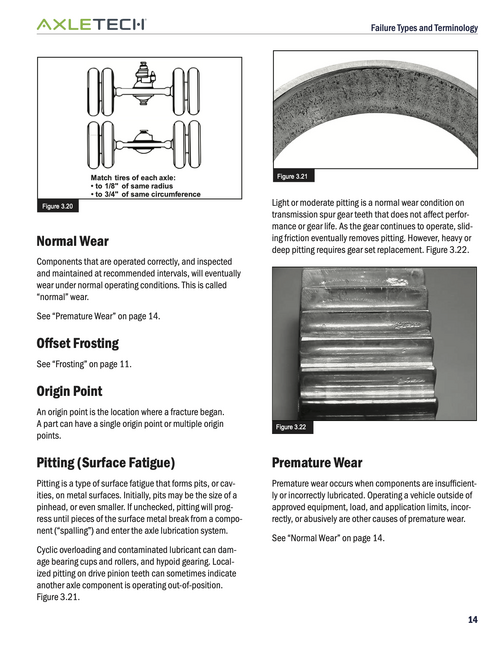

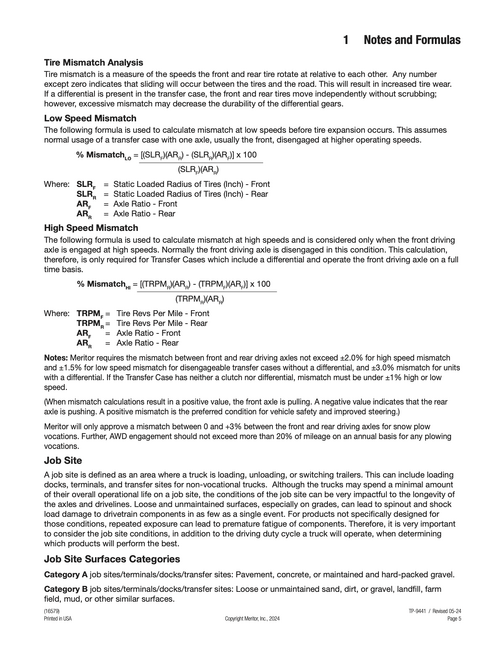

From Axle Tech's AMT-0445 Failure Analysis document.

From Dana/Spicer Application Guide DAAG-0080.

From Meritor's Technical Bulletin TP-9441.

But what does that tell us? I have no idea how much is acceptable. Obviously the differential is there to allow for tire size and speed mismatch, so you can turn and all that.

So I'd assume what you're worried about is heat from asking the differential to have a constant mismatch. When you go straight with perfect tires the two sides are turning at the same speed so the differential isn't differential'ing.

But when there is a mismatch the spider is slowly turning, building heat. I'd think mechanically that shouldn't be a problem as long as it's not excessive and you have enough lube in good shape. It's doing this all the time anyway, as you drift left and right, the road curves, normal air pressure differences, etc.

With an auto locker or limited slip excessive differences might be a more significant problem, that might be wearing couplers, friction packs, pins.

I couldn't find anything Toyota that says this but it's a commonly specified thing for commercial trucks. They variously seem to fall in the 1.5% mismatch as a maximum. If that is applied here then using a brand new slightly more than 16/32" should be matched with nothing more worn than 8/32".

My suspicion is that across a regular axle, no LSD or auto locker, that is conservative. OTOH if you have a LSD that is probably not a bad rule of thumb.

It's even harder to find recommendations for front-to-back when you have a transfer case. I found some references in 4WD tractors that suggest you want 0% mismatch up to a 5% forward bias (e.g. the front axle pulling rather than the rear axle pushing). That might be more about control than wear, I dunno. Then again I've always understood that new tires go on the back, not the front. So control again, e.g. under steer, not over rather than an axle wear issue?

From Axle Tech's AMT-0445 Failure Analysis document.

From Dana/Spicer Application Guide DAAG-0080.

From Meritor's Technical Bulletin TP-9441.

Last edited:

so @DaveInDenver how consistent do you think the tires are when first popping out of the mold? As I've been relying on diameter difference for the analysis I realize inferring that from tread depth changes could be flawed if the tires were different sizes to begin with. next time I do this I am going to use a flexible tape measure to attempt to compare circumference...

New tires are recommended on the back for steering control. You could end up with oversteer in low traction conditions even without throttle input. I had this happen all the time in my old Jetta that had snowtires up front and questionable all seasons on the rear. It was easier to manage with FWD but you needed to respect it.

This thread is really geeking out. Tim I believe you are 100% fine as these trucks have completely open diffs. A vehicle like a Subaru with some sort of LSD is way more sensitive. Front to back probably in theory could be at more risk as the full time transfer case has a LSD but we all know the front tires have to take a longer arch when turning and therefore the TC should have that tolerance built into it.

Subaru's are the most sensitive to my knowledge. Plus in that case you're playing with smaller tires where differences in tread depth represent a larger portion of overall diameter.

This thread is really geeking out. Tim I believe you are 100% fine as these trucks have completely open diffs. A vehicle like a Subaru with some sort of LSD is way more sensitive. Front to back probably in theory could be at more risk as the full time transfer case has a LSD but we all know the front tires have to take a longer arch when turning and therefore the TC should have that tolerance built into it.

Subaru's are the most sensitive to my knowledge. Plus in that case you're playing with smaller tires where differences in tread depth represent a larger portion of overall diameter.

DaveInDenver

Rising Sun Ham Guru

Yeah, Tim, I have no idea on tolerance. Gotta be some sort of industry standard for that and any manufacturing in 2025 would surely be ISO compliant. About all I can find searching is Summit talking about race slicks. They talk about 1/2" to 3/4" inch roll out difference in circumference. Race slicks are pretty tall tires, too.

They might take more care in making specialty tires but that's probably a decent guess. Which would mean if you take worst case of 3/4" on a 103" circumference tire you're looking at +/- 0.7% difference there.

That actually seems kind of high. Our Forester manual doesn't even give a tolerance range, it says all four tires must be the same brand, type and wear to avoid issues. I've never seen anything that countermands that in practical. The ECU will complain if there's mismatch more than 3/32" depth or 1/4" in circumference is what I've read. Never tested or verified that personally.

But if that's what Subaru assumes is possible (and it seems awful tight to get 1/4" in circumference, I'm betting that Internet wisdom means 1/4" in diameter) then you're looking at more like 0.25% difference in circumference. The reason I think that it's 1/4" in diameter is that falls into the ~1.5% range difference that I calculated. It's very hard to believe anything mass manufactured and driven in the real world could hit and keep tenths of a percent tolerance. Just letting your air pressure drift and payload move around is going to get you a whole percent of variance.

They might take more care in making specialty tires but that's probably a decent guess. Which would mean if you take worst case of 3/4" on a 103" circumference tire you're looking at +/- 0.7% difference there.

That actually seems kind of high. Our Forester manual doesn't even give a tolerance range, it says all four tires must be the same brand, type and wear to avoid issues. I've never seen anything that countermands that in practical. The ECU will complain if there's mismatch more than 3/32" depth or 1/4" in circumference is what I've read. Never tested or verified that personally.

But if that's what Subaru assumes is possible (and it seems awful tight to get 1/4" in circumference, I'm betting that Internet wisdom means 1/4" in diameter) then you're looking at more like 0.25% difference in circumference. The reason I think that it's 1/4" in diameter is that falls into the ~1.5% range difference that I calculated. It's very hard to believe anything mass manufactured and driven in the real world could hit and keep tenths of a percent tolerance. Just letting your air pressure drift and payload move around is going to get you a whole percent of variance.

Last edited:

DaveInDenver

Rising Sun Ham Guru

FWIW, regards to Toyota with center diffs. They use a Torsen T3 type in the t-case, at least with 4Runner, FJC. I assume that's also true in the big Land Cruiser wagons.

They also use the Torsen in the rear end (not sure it's a T3, which is the planetary type that allows 40:60 splits and stuff) of the GR86. Someone on another forum asked about using a different sized spare.

www.gr86.org

www.gr86.org

"Torsen’s reply:

Thanks for contacting Torsen. Torsen differentials have been qualified in a number of applications to work with mini-spare tire situations. Some of these have been as much 25% smaller than the main tire. For differences less than .25", it doesn't impact it too much. But be advised that the differential will tend to bias more to the larger tire, so that could lead to an unintended yawing tendency under high-throttle situations. I would advise keeping the speed and distance to the limitations typically associated with spare tires should you have to use it."

But how much difference is the center diff going to see with 1% of tire at one corner? The axle differential is there to deal with side-to-side. Will the two driveshafts have much change in torque split? I gotta think it's hardly much.

Now if you ask the center diff or even a part time t-case to deal with both tires on one axle being significantly different than the other, that would upset the split and might wear things fast and cause serious drivetrain wind up. But even there, you probably wouldn't notice until you do something silly like run 4.10 front and 4.56 rear gears, so ~10% sort of mismatch.

Subaru in this respect have torque vectoring that can allow just one wheel to get traction, so some of them have axle LSDs. Our Forester does not, it's a manual so just got the 50:50 center diff and open axle diffs. But the more fancy models and WRX get biased transfer case splits and left-right traction control in the axles.

One thing I might ask is what about TRAC and VSC? Those might not like seeing too much difference in wheel RPM, right? They are actually sensing the wheel speeds using ring counters. They'll know revs per mile, at least implicitly. How do they deal with variance? It's got to be more than just simple matching, it's got to be a rate of change situation. If the two tires are different by 10 revolution over a mile that's not slipping. If one tire changes by 90 degrees, so 25% of the ring pulses, in 2 seconds that would be a slip. It might not care at all below a slow delta threshold.

They also use the Torsen in the rear end (not sure it's a T3, which is the planetary type that allows 40:60 splits and stuff) of the GR86. Someone on another forum asked about using a different sized spare.

Torsen LSD and spare tires

There has been some discussion here on the impacts of mounting a spare tire on the rear axle, mainly on its impacts on the Torsten LSD. My question as more to do with using a 17” spare which has a slightly smaller diameter than the 18” standard size, though they answered it with respect to a...

"Torsen’s reply:

Thanks for contacting Torsen. Torsen differentials have been qualified in a number of applications to work with mini-spare tire situations. Some of these have been as much 25% smaller than the main tire. For differences less than .25", it doesn't impact it too much. But be advised that the differential will tend to bias more to the larger tire, so that could lead to an unintended yawing tendency under high-throttle situations. I would advise keeping the speed and distance to the limitations typically associated with spare tires should you have to use it."

But how much difference is the center diff going to see with 1% of tire at one corner? The axle differential is there to deal with side-to-side. Will the two driveshafts have much change in torque split? I gotta think it's hardly much.

Now if you ask the center diff or even a part time t-case to deal with both tires on one axle being significantly different than the other, that would upset the split and might wear things fast and cause serious drivetrain wind up. But even there, you probably wouldn't notice until you do something silly like run 4.10 front and 4.56 rear gears, so ~10% sort of mismatch.

Subaru in this respect have torque vectoring that can allow just one wheel to get traction, so some of them have axle LSDs. Our Forester does not, it's a manual so just got the 50:50 center diff and open axle diffs. But the more fancy models and WRX get biased transfer case splits and left-right traction control in the axles.

One thing I might ask is what about TRAC and VSC? Those might not like seeing too much difference in wheel RPM, right? They are actually sensing the wheel speeds using ring counters. They'll know revs per mile, at least implicitly. How do they deal with variance? It's got to be more than just simple matching, it's got to be a rate of change situation. If the two tires are different by 10 revolution over a mile that's not slipping. If one tire changes by 90 degrees, so 25% of the ring pulses, in 2 seconds that would be a slip. It might not care at all below a slow delta threshold.

Last edited: