I'm feeling like a bit of an idiot right now... I can't get it to start. I rejetted the carb a bit richer (plugs read lean), checked to make sure I was getting spark, and it won't start. I checked compression, and it's not looking too good. 1-6 read: 80, 85, 70, 65, 55, 70... I'm pretty high up here, so fairly low compression is expected, but that's both too low and too wide of a spread. Right before I bought it everything spec'd out just above 100 with one standout a bit higher (granted, this was at about 5k' compared to my 8k'). I might be in for some expense here, as I'm no where near equipped for what I think this means...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trigger Pulled

- Thread starter spectre6000

- Start date

Well... I did eventually get it to start, and once it did it ran like a top. Engine braking was pretty excellent as well (just as good as my 4Runner was), so I'm guessing something was wrong with my compression gauge (it's an old cheapie and not the most user friendly). I drove it around near the house a bit, and everything checked out perfectly. Then I got bold and went down into Arvada to try to dial it in a bit at an altitude more representative of my daily drive. I stopped at the AutoZone near my wife's office and got a light bulb I knew was out, then it refused to start. I just about killed the battery trying, then I bummed the AutoZone's portable jumper. It wasn't much use either. One of the employees brought his old Chevy minivan over and we jumped it from there. That really got the starter turning and eventually started it. I drove home just in time to beat what has become some pretty good snow.

So now I have to figure out why it doesn't like to start. The AutoZone guy suggested the starter might be on its way out and drawing too much current, though that doesn't seem like anything I've ever seen/heard before. Anyone have any ideas?

At one point while I was testing things out and waiting for the engine to cool down a bit, I rebuilt the trailing arm linkage. It tightened the steering up a smidge, but there's still some work to do there.

Point of note, progressive carbs are far more difficult to jet by ear. I'm going to need a wideband to feel comfortable with this.

So now I have to figure out why it doesn't like to start. The AutoZone guy suggested the starter might be on its way out and drawing too much current, though that doesn't seem like anything I've ever seen/heard before. Anyone have any ideas?

At one point while I was testing things out and waiting for the engine to cool down a bit, I rebuilt the trailing arm linkage. It tightened the steering up a smidge, but there's still some work to do there.

Point of note, progressive carbs are far more difficult to jet by ear. I'm going to need a wideband to feel comfortable with this.

MDH33

Hard Core 4+

When it's not starting, can you see any fuel in the site glass? Has me thinking you might be running it so lean it's possibly overheating and vapor locking. I recall you mentioning the temp gauge not reading accurately.

It starts easier when it's just been run, and yes there is fuel in the sight glass. I read something about a fusible link having to do with the engine starting. Anyone know anything about that?

RicardoJM

Hard Core 4+

The fuseable link came after your rig. What is your start up procedure?

2 pumps of the accelerator, pull the choke and turn the key. Without choke the mixture won't be correct for a cold engine. What is your timing set at? Is the choke working? Sometimes the cable is not fully fastened and pulling the knob does not engage the choke. You might also want to confirm the accelerator pump is squirting fuel into the primary barrel. I know you just rebuilt the carb and it should be good - but the symptoms you describe would be consistent with either of these items.

2 pumps of the accelerator, pull the choke and turn the key. Without choke the mixture won't be correct for a cold engine. What is your timing set at? Is the choke working? Sometimes the cable is not fully fastened and pulling the knob does not engage the choke. You might also want to confirm the accelerator pump is squirting fuel into the primary barrel. I know you just rebuilt the carb and it should be good - but the symptoms you describe would be consistent with either of these items.

RicardoJM

Hard Core 4+

Another item to check is your ground connections. Negative post to the frame or engine block - I've seen it both ways. There is also a ground strap from the frame to the starter area, this one is a bit hazy to my recollection - perhaps some can better describe it. For the ground connections you should clean them up to shiny metal and then reattach. Finally check the battery post connection to insure in is solid and not cracked.

Startup procedure is still being sorted out. My current best guess is:

- clutch in

- choke out if the engine is cold or otherwise unresponsive

- turn key

- If it doesn't catch immediately I'll put the pedal down

- If it continues not catching I'll pump it to squirt the accelerator pump

- If it still won't start I'll let it rest a few seconds to let any heat work its way into things

Timing has the BB about half a BB's width from the bottom of the window (about 4 degrees advanced).

Accelerator pump is confirmed functional.

I'll check the grounds and such in the morning as suggested. A crappy ground at the block would cause a pretty weak spark consistent with what I'm seeing.

When I got back from picking my wife up from work (in her car), I tried to start the 40. It attempted to start a few times, but wouldn't catch. I did notice the starter would occasionally whir uncharacteristically as if the solenoid let go and the gear wasn't in contact with the flywheel... It certainly isn't a constant thing (I would have noticed it for sure) AutoZone guy may have been onto something... Maybe a gear reduction starter is in my future...

Idle shutoff solenoid? I might have heard it clicking after shutoff once this afternoon. I didn't think to investigate...

- clutch in

- choke out if the engine is cold or otherwise unresponsive

- turn key

- If it doesn't catch immediately I'll put the pedal down

- If it continues not catching I'll pump it to squirt the accelerator pump

- If it still won't start I'll let it rest a few seconds to let any heat work its way into things

Timing has the BB about half a BB's width from the bottom of the window (about 4 degrees advanced).

Accelerator pump is confirmed functional.

I'll check the grounds and such in the morning as suggested. A crappy ground at the block would cause a pretty weak spark consistent with what I'm seeing.

When I got back from picking my wife up from work (in her car), I tried to start the 40. It attempted to start a few times, but wouldn't catch. I did notice the starter would occasionally whir uncharacteristically as if the solenoid let go and the gear wasn't in contact with the flywheel... It certainly isn't a constant thing (I would have noticed it for sure) AutoZone guy may have been onto something... Maybe a gear reduction starter is in my future...

Idle shutoff solenoid? I might have heard it clicking after shutoff once this afternoon. I didn't think to investigate...

I think I found my starting problem... I cleaned up all of the grounds (none of which were in bad shape, but it never hurts). I checked the idle shutoff solenoid (reached in through the vent window and listened for the click while I turned the key between ACC and ON). And I removed the ballast resistor (just for grins). Nada. Finally I got the bright idea to hook up my timing light and see what's going on. At BEST I'm getting 30 RPM from the starter, about 1/3 of the time saw 10 RPM, and when the solenoid let go it was a cool 0. It turns out that what I was mistaking for the engine occasionally trying to catch was the solenoid cutting out and the only thing that was turning was the starter itself! Someone correct me if I'm wrong, but most starters turn at or near 200 RPM. I've not heard too many 40s trying to start (read: only mine), but it seems 30 isn't enough...

RicardoJM

Hard Core 4+

I'm not sure of the rpm question, but I definately know that your Idle Cutoff Solenoid (ICS) needs to have constant power when you are starting (and running) the engine. As soon as the key turns to the on position it (ICS) should have power and as soon as you turn the key to the off position it (ICS) should not have power. Nice debugging work, now get that fixed and weld in an O2 bung so you can borrow my Zeitronix unit.

I'm not sure of the rpm question, but I definately know that your Idle Cutoff Solenoid (ICS) needs to have constant power when you are starting (and running) the engine. As soon as the key turns to the on position it (ICS) should have power and as soon as you turn the key to the off position it (ICS) should not have power. Nice debugging work, now get that fixed and weld in an O2 bung so you can borrow my Zeitronix unit.

Yes! I was contemplating searching out what the run, but I'd much rather borrow one for the time being.

I'm about to go pull the belts off and run down to O'Reilly for a starter. Wish me luck, and maybe I'll be able to take you up on the wideband offer soon.

SteveH

Hard Core 4+

My '78 has the OEM non-gear-reduction starter and has always cranked like a 6 volt Farmall at 5 degrees F. Well, maybe a bit better than that. I have installed other starters (non-GR) and they all crank that way. It always starts, but I do appreciate gear-reduction starters that don't sound so anemic.

You might source a later starter for your truck, and you'll pick up a lot of cranking RPM that way. Tell the store you need a starter for an '87 FJ60.

You might source a later starter for your truck, and you'll pick up a lot of cranking RPM that way. Tell the store you need a starter for an '87 FJ60.

rover67

Rising Sun Member

Toyota sells reman starters for a decent price. Not sure if I'd bother with NAPA.

Boudler Toyota gives Rising Sun Members a deal.

Boudler Toyota gives Rising Sun Members a deal.

Steve, How many RPM does it turn? 30 RPM seems low even for a 6V tractor.

I called CDan, and he's gone all week for a family emergency according to his outgoing voicemail message. I was REALLY unimpressed with Boulder Toyota the one time I tried to buy parts from them. I don't do business with companies that act that way. Not going into details.

I got a GR starter at O'Reilly. I also got two random belts (as in they don't fit a Land Cruiser). So now I'm completely down (no belts) and it's too damn cold, dark, and snowy out there to do anything about it...

So now I'm completely down (no belts) and it's too damn cold, dark, and snowy out there to do anything about it...  I'm really getting sick of this no garage business.

I'm really getting sick of this no garage business.  My company had better start making money soon.

My company had better start making money soon.

I have meetings all day for the next two days tomorrow in Arvada, and it would be REALLY nice if I didn't have to play the one car game and leave to go pick up my wife in the middle of it.

The only positive thing to happen today is that I got a lock for the spare that both fit and functioned as it should...

I called CDan, and he's gone all week for a family emergency according to his outgoing voicemail message. I was REALLY unimpressed with Boulder Toyota the one time I tried to buy parts from them. I don't do business with companies that act that way. Not going into details.

I got a GR starter at O'Reilly. I also got two random belts (as in they don't fit a Land Cruiser).

I have meetings all day for the next two days tomorrow in Arvada, and it would be REALLY nice if I didn't have to play the one car game and leave to go pick up my wife in the middle of it.

The only positive thing to happen today is that I got a lock for the spare that both fit and functioned as it should...

While I'm thinking about it, how do you guys tension these belts? It's simple enough (and it may just be that all of the hoses and belts are too cold to even pretend to flex), but I don't think I could have tensioned them the way I was going about it. I gave it a try, but even if the belts were the right ones I don't know that I would have been able to get proper tension on them... The Toyota Manual is mum and the Haynes manual refers to a photo they seem to have forgotten to include...

rover67

Rising Sun Member

I usually tighten them until I think they feel right but usually stay on the loose side... Drive it and if it squeals then a little more. I like them looser than tighter so bearings in stuff like alternators don't get trashed too fast. Probably not the answer you were looking for..... Set the belt the same way you did it on the air cooled stuff. Maybe use the rule for deflection distance of the belt given a certain amount of pressure applied to it. Porsches had a sticker on the deck lid that gave some number, can't remember now.

I noticed when i went to go get belts for my 40 a while back it took a few tries. there were several belt routings for different years with different accessories so it's no surprise the box stores are wrong. Take your old belts next time, it's the only way to get close. I think when I looked at the dealer for my year rig there were like 4 different routings possible... all with different belts.

Bummer on boulder toyota. I like them. eat breakfast with Jerry on occasion and I like to give them the business. For me it has always been a simple matter of walking up, asking for parts and reminding them I am a member of rising sun. Not sure what the deal is.

When I had the non gear reduction starter It started super slow also. can't guess on RPM but it sounded slooooowwww... like total dead battery slow.

I noticed when i went to go get belts for my 40 a while back it took a few tries. there were several belt routings for different years with different accessories so it's no surprise the box stores are wrong. Take your old belts next time, it's the only way to get close. I think when I looked at the dealer for my year rig there were like 4 different routings possible... all with different belts.

Bummer on boulder toyota. I like them. eat breakfast with Jerry on occasion and I like to give them the business. For me it has always been a simple matter of walking up, asking for parts and reminding them I am a member of rising sun. Not sure what the deal is.

When I had the non gear reduction starter It started super slow also. can't guess on RPM but it sounded slooooowwww... like total dead battery slow.

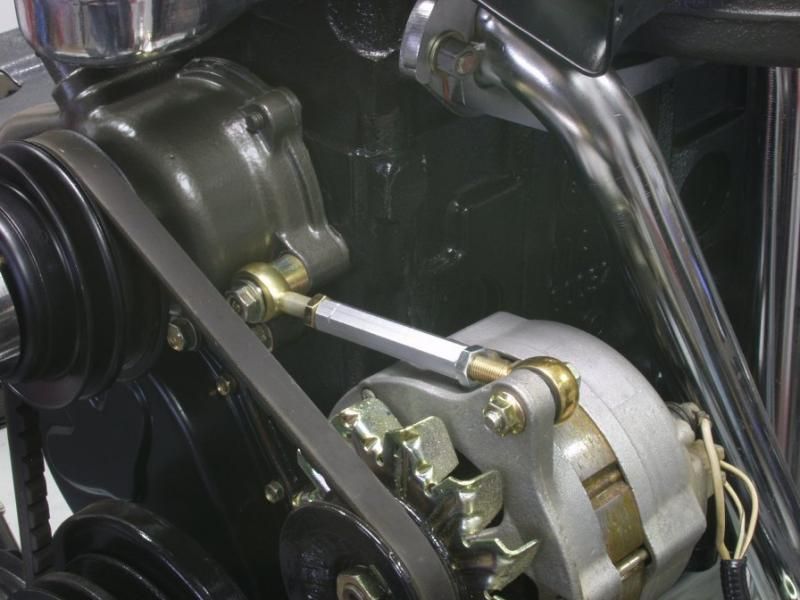

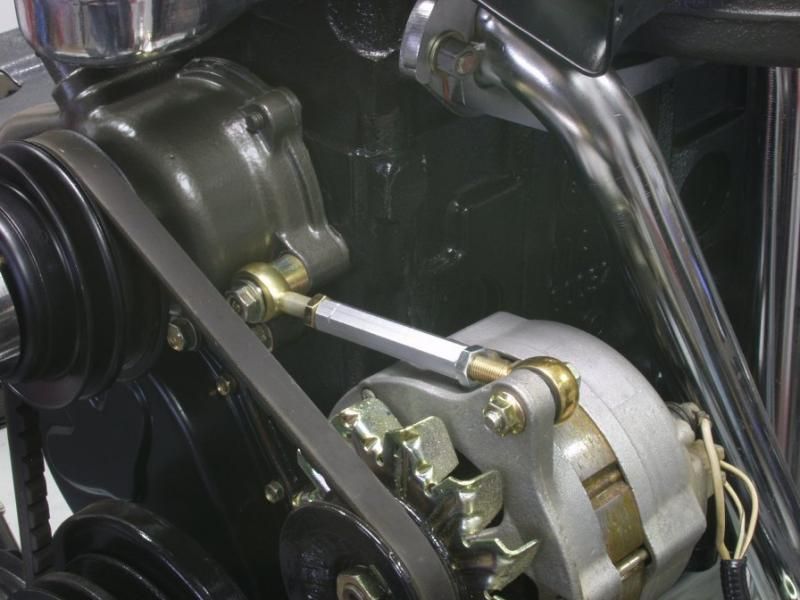

What I'm having issues with is getting tension in the first place. With the aircooled stuff it's accomplished with shims. Here it's accomplished by rotating the driven devices out on pivots. On the alternator, for instance, I couldn't get enough leverage to overcome the stiffness of the belt (enhanced by the cold). I tried to lever it with a wrench against the engine block, but that was just about as useless. It likely would have been a similar affair with the air pump belt if it were long enough to get on there in the first place. I use the deflection method, and I'm getting inches instead of millimeters with my best tensioning efforts...

rover67

Rising Sun Member

ahh gotcha.

yep, the shims work a treat. I always liked that method.

I just use a big ole pry bar on the cruiser.... 2 footer.

yep, the shims work a treat. I always liked that method.

I just use a big ole pry bar on the cruiser.... 2 footer.

RicardoJM

Hard Core 4+

I used my hi-lift handle. Easy leverage with one hand while e other tightened the bolt to secure the alternator in place.

ahh gotcha.

yep, the shims work a treat. I always liked that method.

I just use a big ole pry bar on the cruiser.... 2 footer.

Am I correct then to lever against the engine case like that? The angles don't seem quite right. Is it the same approach with the air pump on the other side?

I'm really liking this idea:

I'm really liking this idea:

rover67

Rising Sun Member

some rigs came with a tensioning bolt that went on the arm that has the big slot in it. you could snag that kinda setup from somebody. it works well.

i'll look for a pic.

i'll look for a pic.