DaveInDenver

Rising Sun Ham Guru

A few mistakes were made in that Bronco recovery. It's really an interesting study, not just for the recovery but medical assessment oversights by even the triage doctor at the hospital. See how many things he talks about that Bill Burke and others touch on.

www.bronco6g.com

www.bronco6g.com

irate4x4.com

irate4x4.com

And on YouTube.

View: https://youtu.be/NrIR_4IPIbk

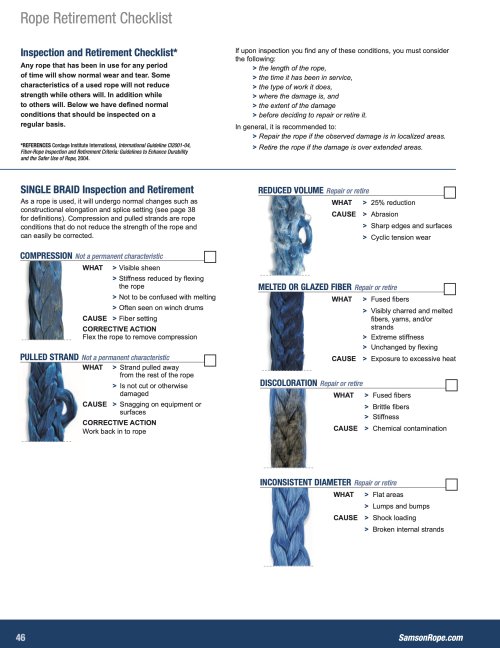

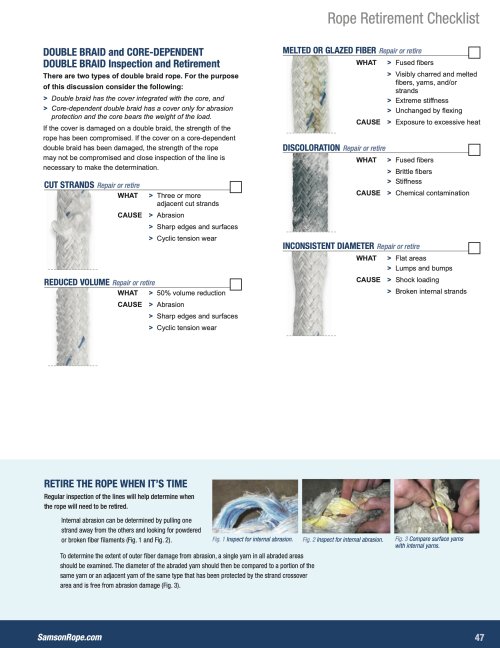

Recovery gear deep dive: shackles, straps and kinetic ropes, what to buy!

Do you guys seriously trust these factory loops which aren’t stamped with a rating and are NOT completely welded on both sides? I'm probably older than most on this forum. People of my generation mostly consider these tie down points, as in strap it on the trailer ; not recovery points.

Soft shackles and kinetic ropes

Anyone ever had a soft shackle get cut and turn a kinetic rope into a missile? Had a situation go down today and wondering if this is a common thing.

And on YouTube.

View: https://youtu.be/NrIR_4IPIbk

Last edited: