Got the flywheel back - beautiful. I think I am going to pull the pan and do the gasket just because everything else under there has cleaned up so well and my OCD is kicking in.

That's the Martin we know and love!

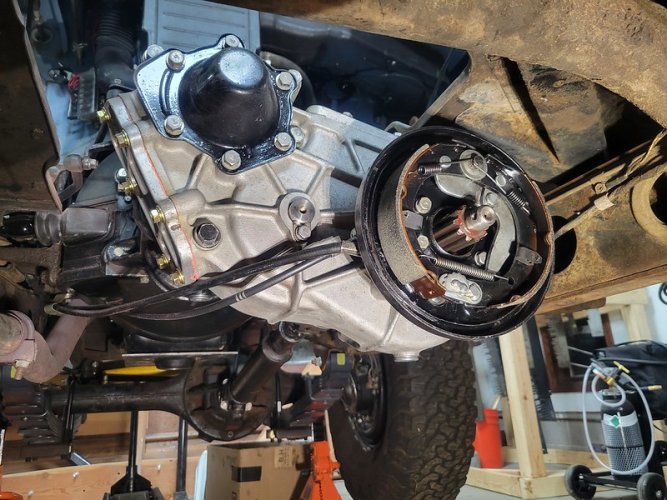

Got the flywheel back - beautiful. I think I am going to pull the pan and do the gasket just because everything else under there has cleaned up so well and my OCD is kicking in.

I pulled the pan on my 60 to do the RMS. I wanted to check the lower end since I never had … and I figured why not just buy a new pan and hardware while I’m at it haha. It takes maybe 7 minutes to pull it and about 20 to install it. I had never done an RMS and didn’t want to mess around with PVC pipe as a driver and worry about messing up the lip of the seal. It was super easy to pop it in, took less than a minute.

With that tungsten carbide bit, only took a few minutes. I used the same type of bit to grind out a broken tap in my 3RB block. Super handy.Super clean work. How long did it take to Dremel that race enough to pull the pieces out?

Thanks! Yeah, I think the layers of leaking oil and stuck on grime preserved a lot. Some of those parts are barely chipped.nice work martin, crazy awesome chape those black parts are in. it's going to drive so nice

Good idea! I don't own a hair drier as I don't have hair, but I do have a heat gun at work I can borrow. Thanks for the tip.Try some heat from a hair drier to give it new memory.

Thin layer of fipg on everything and a blob in each corner?

This has worked for me on several 2Fs. I used cheap, small zip ties to tie the gasket to the pan, and then snipped and removed them as I went along.