You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

got a 40 - now it begins

- Thread starter simps80

- Start date

simps80

Rising Sun Member

Thanks Matt!

So now that the thrash is done.

Time to tune.

It won't run unless its half choked and I know that won't pass smog...now I am in no hurry here..I am going to try to learn cause I am a carb moron

...

So monday I started about the business of troubleshooting the idle...

All indications were vacuum leak..choke to idle..missing..unburned fuel..or idle circuit problem...I know the solenoid works..it clicks with key..

Ether around manifold and carb base made it stumble and almost die (thought ether would do opposite but it didn't)

So I torqued all manifold bolts..they were a touch loose..

That actually yielded a vacuum improvement..it went from just under 14 and dropping with stumble to just over 15 and stumble..

Put a turn on carb studs and 3 of 4 tightened a bit.

The 4th just spun..right off the bat..

So either stud broke or manifold stripped...

It was the latter..

So I did some research..seems to repair threads best option (short of tig welding hole and redrilling) was a time-sert..I had used helicoils before but apparently this timesert deal was more dependable...

So I called around and found a 8mmx1.25 kit at triple a metric..

Drove fown and picked it up this afternoon...spendy but quality..

Its a 4 step process..

The kit came with:

1. Drill bit

2. Countersink bit

3. Tap

4. Timesert insertion tool.

5. A few timeserts.

So I drilled the hole with the bit stopping .25 inches from bottom of hole as prescribed and measured.

Then countersuck the top..their bit is built to countersink a precise amount..but I stopped a bit short anyway cause I was scared..lol

Then tapped it again .25 inches from bottom.

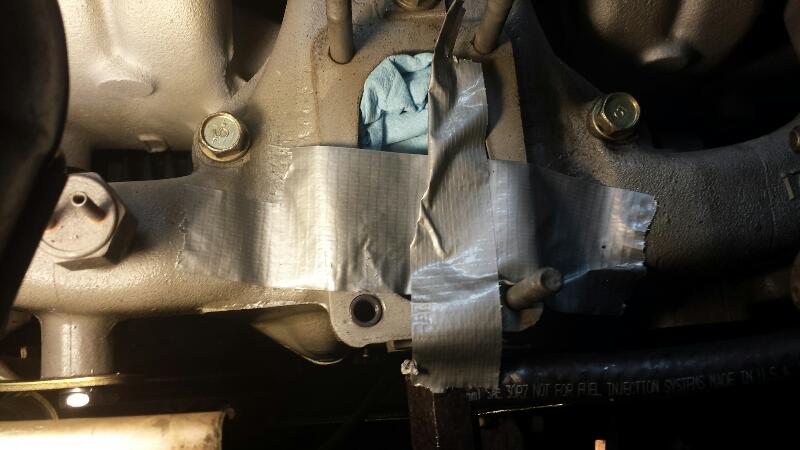

Yielding this

I had previously stuffed a towel and duck tape in the hole but removed it here.

Then using their insertion tool as instructed I inserted the timesert "as it will get hard on last two threads then easy as it is fully inserted"

That yielded this...

I re stuffed the hole cause I was going to file down the tiny ridge that was proud of the manifold..then I called mike and he said "why not just use that countersink bit on the insulator and remove a tiny bit"

Man that was smart..

Anyway..finished up mounting carb tonight

It definitely is improved.... after some gyrations with screws...I can now idle off choke..

But its real rough at about 850..smooth only higher..

Still smell unburned fuel...and it is still coming out main nozzle at idle

So will continue on that..

Its fun..for now..been reading a lot..

So now that the thrash is done.

Time to tune.

It won't run unless its half choked and I know that won't pass smog...now I am in no hurry here..I am going to try to learn cause I am a carb moron

...

So monday I started about the business of troubleshooting the idle...

All indications were vacuum leak..choke to idle..missing..unburned fuel..or idle circuit problem...I know the solenoid works..it clicks with key..

Ether around manifold and carb base made it stumble and almost die (thought ether would do opposite but it didn't)

So I torqued all manifold bolts..they were a touch loose..

That actually yielded a vacuum improvement..it went from just under 14 and dropping with stumble to just over 15 and stumble..

Put a turn on carb studs and 3 of 4 tightened a bit.

The 4th just spun..right off the bat..

So either stud broke or manifold stripped...

It was the latter..

So I did some research..seems to repair threads best option (short of tig welding hole and redrilling) was a time-sert..I had used helicoils before but apparently this timesert deal was more dependable...

So I called around and found a 8mmx1.25 kit at triple a metric..

Drove fown and picked it up this afternoon...spendy but quality..

Its a 4 step process..

The kit came with:

1. Drill bit

2. Countersink bit

3. Tap

4. Timesert insertion tool.

5. A few timeserts.

So I drilled the hole with the bit stopping .25 inches from bottom of hole as prescribed and measured.

Then countersuck the top..their bit is built to countersink a precise amount..but I stopped a bit short anyway cause I was scared..lol

Then tapped it again .25 inches from bottom.

Yielding this

I had previously stuffed a towel and duck tape in the hole but removed it here.

Then using their insertion tool as instructed I inserted the timesert "as it will get hard on last two threads then easy as it is fully inserted"

That yielded this...

I re stuffed the hole cause I was going to file down the tiny ridge that was proud of the manifold..then I called mike and he said "why not just use that countersink bit on the insulator and remove a tiny bit"

Man that was smart..

Anyway..finished up mounting carb tonight

It definitely is improved.... after some gyrations with screws...I can now idle off choke..

But its real rough at about 850..smooth only higher..

Still smell unburned fuel...and it is still coming out main nozzle at idle

So will continue on that..

Its fun..for now..been reading a lot..

Last edited:

simps80

Rising Sun Member

Ok that last post was too tech heavy...

So after that...

I finished off the night with a sweet score from the rally...

A new inner tcase shifter boot...nla and no one sells a repop...

But even better I upgraded from ghetto ebay manual to private reserve de la Ige mint ash manual.

Thank you Ige!!

So after that...

I finished off the night with a sweet score from the rally...

A new inner tcase shifter boot...nla and no one sells a repop...

But even better I upgraded from ghetto ebay manual to private reserve de la Ige mint ash manual.

Thank you Ige!!

Rzeppa

Rising Sun Member

Oh, remember when I mentioned about potentially overtightening the bolts that hold the manifolds to each other, that the intake is aluminum and if you overtighten it can strip?

I forgot to mention the carb studs. BTDT Same thing. I got a helicoil in one of my manifolds (forget which rig).

Same thing. I got a helicoil in one of my manifolds (forget which rig).

I forgot to mention the carb studs. BTDT

wesintl

Moderator

I'm surprised mike didn't talk you into a High po f manifold with the runners

simps80

Rising Sun Member

I'm surprised mike didn't talk you into a High po f manifold with the runners

Kinda wish I had...that and a header after this..

Oh, remember when I mentioned about potentially overtightening the bolts that hold the manifolds to each other, that the intake is aluminum and if you overtighten it can strip?

I forgot to mention the carb studs. BTDTSame thing. I got a helicoil in one of my manifolds (forget which rig).

I heeded that advice....more on that in a minute

So.....

I just now got the idle problem fixed.

WARNING MAY BE BORING TO EXPERIENCED CARB PEOPLE

It was 2 (maybe 3) separate problems.

I think I read every single "wont idle" thread on mud.

It is funny to see the thought process of some of the authorities on mud evolve over time. And frustrating how there are not very many pictures explaining what the heavy hitters say..I think they take their knowledge level for granted...

Pin_head was eventually right in my case as well.

He says over and over..half choke to idle plus fuel out the main nozzle is vacuum leak or no fuel in idle curcuit.

For me it was both.

But the idle circuit issue wasn't clear to me so I am documenting it here..wasted way too much time and probably 3 to 4 extra removal/installation cycles of my carb.

I eventually pulled the carb off again and set out to map the idle circuit through the carb..

I pulled the idle solenoid and checked it on the battery again..it worked.

I then took carb cleaner and sprayed it into the hole the solenoid goes in..it went nowhere.

I had a spare carb..did same..

Found it dribbles out the main barrel at the bottom of carb where a tiny hole is below the butterfly (which incidentally I learned should be essentially shut at idle)..

Just as throttle is applied and butterfly starts to open..the "transition slot" appears..this handles throttle transition fuel from idle to accelerate...

I had nothing coming out the idle circuit.

Used compressed air..same thing..

Started taking carb apart...

I noticed the gasket between base and bowl was very slightly off..

Covering a passageway...that I later mapped out to be the idle circuit...

So I pieced together the circuit blowing air through each component starting at the base where I knew the exit was.

I eventually proved each component was clear.

So I knew it had been blocked by the gasket that I had found offset that was blocking the mystery passage I later proved to myself to be the idle circuit.

Here are pics in case any future reader needs to know..mapping circuit up through the components..

You can see how the gasket can be offset enough to block stuff and the carb will still go together

Last edited:

simps80

Rising Sun Member

So that was problem one.

I put it together this time aligning gaskets with tiny screwdrivers long enough to make it through.

Now before air horn went on i blow air through the asseembly to make sure it came through base..to reassure myself that the gaskets didnt shift. (I used a tiny bit of gasket adhesive on the widest parts to make sure)

.

.

Now..this was after I had eliminated all the possibilities. ..

I had capped brake booster and pcv...capped off emissions..

Done the carb cleaner dance around the manifold and carb base etc etc etc...

So I was Pissed!!# when I bolted my newly reassembled carb up and it still had fuel coming out main nozzle.....

One very notable delta was I could now affect idle with the mixture screw on the back..so I knew that was a resolved issue..there was fuel supply in idle circuit.

That was last night....

Today in a desperate act I was going to swap carbs with the old crusty one on the shelf...

So I took it all back apart..then happened to read Jeffs reply above to my stripping the carb stud post....

The bolts holding the manifolds together...hmmm...I never rechecked those...I knew the manifolds needed retorqued after the first time it got hot and cooled and I had done that. .

I had retorqued (and retorqued again) the manifold mounting hardware during this hunt for vacuum leak again as well

.even going 2 lbs tighter on each...

The misting of ether wasnt making changes in idle anymore..but there still had to be a leak cause of the fuel out main nozzle still..

The internal bolts holding the manifolds to each other.. I had never checked those..

So I took a wrench to those bolts and one of them was real loose...I mean real loose..

I had been surprised that since starting this that the mounting hardware took additional torque at least twice now...

So I should have thought to check the bolts between manifold but I hadn't. ..I had even pulled it apart to check for cracks between manifolds from heat riser even though mine operates perfectly... thanks for that reply jeff it made me think of that as a possible issue. .

Anyway ... tightened that up put on carb and it idles without choke...and for the first time..no fuel out the main nozzle!!!!

The idle screw at the base of the firewall side has intended effects now as well..

So it looks like its solved..now for some actual tuning...I can get over 15 inches of vacuum solid no bouncing now at 800...

So I should be able to adjust it good.

I even took a pic of it idling with no fuel out main nozzle lol...

So yea the conventional wisdom held...

Half choke to idle..

Fuel out main nozzle at idle..

No effect on idle from mixture screw or idle screw..

Equals vacuum leak or idle circuit problem..

Mine was both..just couldn't detect the final (there were multiple) vacuum leak via normal method easily cause it was internal.

I put it together this time aligning gaskets with tiny screwdrivers long enough to make it through.

Now before air horn went on i blow air through the asseembly to make sure it came through base..to reassure myself that the gaskets didnt shift. (I used a tiny bit of gasket adhesive on the widest parts to make sure)

Now..this was after I had eliminated all the possibilities. ..

I had capped brake booster and pcv...capped off emissions..

Done the carb cleaner dance around the manifold and carb base etc etc etc...

So I was Pissed!!# when I bolted my newly reassembled carb up and it still had fuel coming out main nozzle.....

One very notable delta was I could now affect idle with the mixture screw on the back..so I knew that was a resolved issue..there was fuel supply in idle circuit.

That was last night....

Today in a desperate act I was going to swap carbs with the old crusty one on the shelf...

So I took it all back apart..then happened to read Jeffs reply above to my stripping the carb stud post....

The bolts holding the manifolds together...hmmm...I never rechecked those...I knew the manifolds needed retorqued after the first time it got hot and cooled and I had done that. .

I had retorqued (and retorqued again) the manifold mounting hardware during this hunt for vacuum leak again as well

.even going 2 lbs tighter on each...

The misting of ether wasnt making changes in idle anymore..but there still had to be a leak cause of the fuel out main nozzle still..

The internal bolts holding the manifolds to each other.. I had never checked those..

So I took a wrench to those bolts and one of them was real loose...I mean real loose..

I had been surprised that since starting this that the mounting hardware took additional torque at least twice now...

So I should have thought to check the bolts between manifold but I hadn't. ..I had even pulled it apart to check for cracks between manifolds from heat riser even though mine operates perfectly... thanks for that reply jeff it made me think of that as a possible issue. .

Anyway ... tightened that up put on carb and it idles without choke...and for the first time..no fuel out the main nozzle!!!!

The idle screw at the base of the firewall side has intended effects now as well..

So it looks like its solved..now for some actual tuning...I can get over 15 inches of vacuum solid no bouncing now at 800...

So I should be able to adjust it good.

I even took a pic of it idling with no fuel out main nozzle lol...

So yea the conventional wisdom held...

Half choke to idle..

Fuel out main nozzle at idle..

No effect on idle from mixture screw or idle screw..

Equals vacuum leak or idle circuit problem..

Mine was both..just couldn't detect the final (there were multiple) vacuum leak via normal method easily cause it was internal.

Last edited:

simps80

Rising Sun Member

Thanks Matt!

fixing all those problems flushed out the next...

so here's where I am at now.

it will time and idle at 650.

on 4 cylinders.

I thought I was crazy not being able to find line or bb with timing light at 12 or even higher....

at 35!!!!!! it shows up...

would account for high heat....

it appears 5 and 6 are intermittent at best.

pulling 5 and 6 plugs reveal what appears to be oil fouled plugs.

putting the timing light on 1-4 the strobe is solid

on 5 and 6 its intermittent that it fires solid.

but it arcs from cap to ground or plug to ground on plug side.

so arc is good

but 5 and 6 have no effect on 'idle' when pulled.

so ... I think basically 5 and 6 are getting oil fould from pcv

that may be because of oil level being too high.

compression is good...

so I'm thinking of putting an oil separator in live with pcv .

vacuum is good and compression good and spark good

so only thing I can think is pcv is fouling 5 and 6 with oil.

was thinking of just venting to atmosphere for pcv ... but would like it to not have to do that ...

thoughts?

the compression is solid ... so I don't think oil fouling is from broken/bad ring...

any thoughts appreciated.

I know it will fail emissions as it sits even though it idles nice but wayyyyy toooo advanced....

just wondering what's oil fouling 5 and 6..gotta be pcv.....the pcv sucks HARRRDDDD with manifold vacuum.

don't think it could be head or rings with good compression plus head has so little oil to begin with...even if ALL the oil from the head was making it past a valve seal or 2 it wouldn't foul like this...

take a good plug brand new run it for less than 10 minutes its foulded...

mike came and f'd with it for a while and said, set it to 12, clean out cylinders vent pcv to atmosphere run it and see what happens...

gonna try that ...

any other input is appreciated

just don't think its coincidence that pulling 5 and 6 wires doesn't have obvious effect on idle and it runs fine with timing wayyy advanced...

gotta think 5 and 6 fouling is the culprit...but why

fixing all those problems flushed out the next...

so here's where I am at now.

it will time and idle at 650.

on 4 cylinders.

I thought I was crazy not being able to find line or bb with timing light at 12 or even higher....

at 35!!!!!! it shows up...

would account for high heat....

it appears 5 and 6 are intermittent at best.

pulling 5 and 6 plugs reveal what appears to be oil fouled plugs.

putting the timing light on 1-4 the strobe is solid

on 5 and 6 its intermittent that it fires solid.

but it arcs from cap to ground or plug to ground on plug side.

so arc is good

but 5 and 6 have no effect on 'idle' when pulled.

so ... I think basically 5 and 6 are getting oil fould from pcv

that may be because of oil level being too high.

compression is good...

so I'm thinking of putting an oil separator in live with pcv .

vacuum is good and compression good and spark good

so only thing I can think is pcv is fouling 5 and 6 with oil.

was thinking of just venting to atmosphere for pcv ... but would like it to not have to do that ...

thoughts?

the compression is solid ... so I don't think oil fouling is from broken/bad ring...

any thoughts appreciated.

I know it will fail emissions as it sits even though it idles nice but wayyyyy toooo advanced....

just wondering what's oil fouling 5 and 6..gotta be pcv.....the pcv sucks HARRRDDDD with manifold vacuum.

don't think it could be head or rings with good compression plus head has so little oil to begin with...even if ALL the oil from the head was making it past a valve seal or 2 it wouldn't foul like this...

take a good plug brand new run it for less than 10 minutes its foulded...

mike came and f'd with it for a while and said, set it to 12, clean out cylinders vent pcv to atmosphere run it and see what happens...

gonna try that ...

any other input is appreciated

just don't think its coincidence that pulling 5 and 6 wires doesn't have obvious effect on idle and it runs fine with timing wayyy advanced...

gotta think 5 and 6 fouling is the culprit...but why

simps80

Rising Sun Member

Yes and I don't think so

sounds like its time for a leak-down test.

With brand new plugs do you get solid firing on 5 and 6? Trying to figure out if the weak spark is the cause of the plug fouling or the result of the plug fouling.

Distributor shaft not wobbly or worn, possibly providing poor "contact" with rotor and cap?

You could put a temporary catch can on your PCV line to see how much oil it is producing from that source. Mine produces enough oil vapor in my valve cover vent to the air cleaner that I end up with a puddle of oil in my air cleaner housing, but it doesn't foul plugs.

Distributor shaft not wobbly or worn, possibly providing poor "contact" with rotor and cap?

You could put a temporary catch can on your PCV line to see how much oil it is producing from that source. Mine produces enough oil vapor in my valve cover vent to the air cleaner that I end up with a puddle of oil in my air cleaner housing, but it doesn't foul plugs.

simps80

Rising Sun Member

With brand new plugs do you get solid firing on 5 and 6? Trying to figure out if the weak spark is the cause of the plug fouling or the result of the plug fouling.

Distributor shaft not wobbly or worn, possibly providing poor "contact" with rotor and cap?

You could put a temporary catch can on your PCV line to see how much oil it is producing from that source. Mine produces enough oil vapor in my valve cover vent to the air cleaner that I end up with a puddle of oil in my air cleaner housing, but it doesn't foul plugs.

it will fire for a short period of time and then they are fouled again

distributor shaft was solid, new cap, new rotor, new wires and plugs

i am just curious about the pcv doing it so I think I will do the catch can and see if it affects it. it sucks very hard, I still think its possible its sucking oil out and causing the plugs to foul...I'm hoping so...

if it still fouls then I guess I know what's doing it...but I don't want to actually even think about the possibility of something wrong in the cylinder right now

kinda why I don't want to do the leak down...but I will if cleaning it all out, catch can, new plugs, don't work..at least prove what I'm up against

Rzeppa

Rising Sun Member

I assume the PCV valve itself is brand new, right?

simps80

Rising Sun Member

Yes its new.

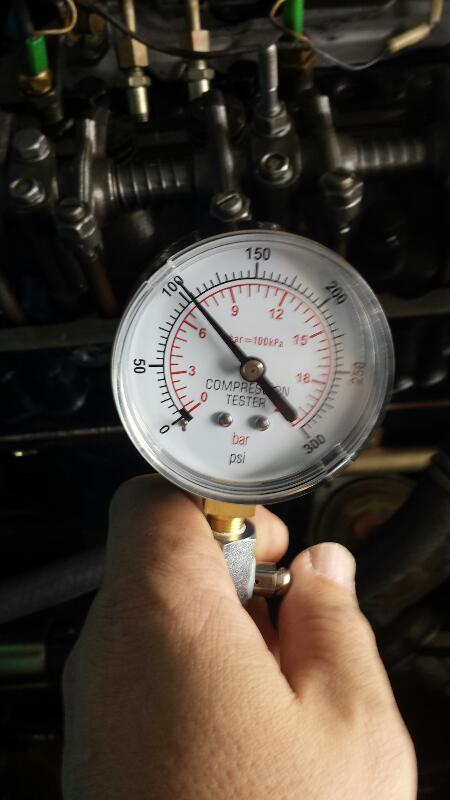

I did a compression test numbers were good 1 to 5 and zero on 6.

I can feel and hear compression but it must be real low.

Need to do some more work to determine if its head or cylinder.

A zero reading to me seems more likely to be valve related..I think rings would read low but not 0

Anyway kind of annoyed with the whole thing right now..so may be a while before I mess with it more..or I may just take iy to Robbie and ask him to make go fix

I did a compression test numbers were good 1 to 5 and zero on 6.

I can feel and hear compression but it must be real low.

Need to do some more work to determine if its head or cylinder.

A zero reading to me seems more likely to be valve related..I think rings would read low but not 0

Anyway kind of annoyed with the whole thing right now..so may be a while before I mess with it more..or I may just take iy to Robbie and ask him to make go fix

rover67

Rising Sun Member

do a quick leak down, throw air in that cyl. and figure out where it's going. could be a tight valve, if you had seats put in the head (not sure what they did when they rebuilt it) they can sink sometimes when it runs for a bit and leak. You can readjust and it will likely be fine if thats the case.

Dont freak out, you're almost there... zero means big leak which can be a good thing.... rings are probably fine as is head gasket.. probably nothing cracked.

Dont freak out, you're almost there... zero means big leak which can be a good thing.... rings are probably fine as is head gasket.. probably nothing cracked.

Rzeppa

Rising Sun Member

I agree with Marco. Probably nothing too serious. Probably a valve issue.

simps80

Rising Sun Member

sounds like its time for a leak-down test.

And that's what I did today.

Got some good advice via pm and text last week.

I couldn't get a quickie air into cylinder rig going cause my compression tester that i was going to use for the spark plug hole fitting is one way air (as expected) but its both a schrader valve and what appeared to be an internal check valve so i couldn't convert it...so I went and picked up this leak down tester at napa

Which btw while a higher quality tool than expected..it was kinda stupid how much it cost..sooo if any of you need to do a leakdown test in the future and dont have one...borrow this one and save the coin...it was kinda fun using it..tested all the cylinders a few times found same problem on 5 as 6 but intermittent which was strange....but that is too far ahead of the story....

I read a bit and watched a video on it then went to garage to determine if I screwed up the rebuild or if it was a valve or what.

The instructions were informative along with aforementioned electronic guidance from fellow rising sunners...

Gonna document the process and thought behind it for any future readers unfamiliar like I was

Basically..not tricky...

Fill cylinder at tdc compression with air and listen where it comes out thats the high level.

First though

-take dipstick out and pcv from side cover.

- Remove radiator cap.

- Open throttle up.

Once the tool is calibrated then put hose in head and hook ip to "air out" of tester.

-if there us signuficant leakage of air as heard or seen on gauge...

Start listening from where the air is escaping..

-if it comes back out intake (via carb) intake valve leaking is likely

-if air out exhaust pipe ..exhaust valve leaking

-if air through coolant (bubbles in radiator or overflow) then thats bad..possible head gasket or crack in coolant flow "circuit" (block/head etc).

-if air comes out adjacent cylinder spark plug hole then blown head gasket likely other cause invlude cracked cylinder wall or head I suppose.

-if air through pcv or dipstick then ring failure most likely

Soo..re-confirmed 0 compression on 6 was still the case..then hooked up leak down tester.

You have to "calibrate" it by hooking up air in then adjusting regulator until it zeroes out on the second "loss gauge" ..

My air pressure isn't high enough to get there but it was high enough for the test. .you can see it "calibrated" below with regulator full open.. now this is with nothing connected to the out (to cylinder) side.

So this is what I found

So if that video is weird...basically 6 at tdc puked air out carb

This was a win for me...I was actually excited.. cause it meant I didn't screw up on the rebuild with rings etc. And the worst case was head comes off back to gunn for a bad intake valve not sealing...

Last edited:

simps80

Rising Sun Member

But it gets better...

These valves have been adjusted probably at least 5 times

But because it was easy..I just backed the intake on 6 way off to see what would happen.

This is what happened:

Here ia compression gauge on 6 after backing off intake valve that was leaking..

105..that is in line with all the rest (cold and dry)

105 on 5

Lowest 100 on 4

104 on 3

102 on 2

105 on 1

These valves have been adjusted probably at least 5 times

But because it was easy..I just backed the intake on 6 way off to see what would happen.

This is what happened:

Here ia compression gauge on 6 after backing off intake valve that was leaking..

105..that is in line with all the rest (cold and dry)

105 on 5

Lowest 100 on 4

104 on 3

102 on 2

105 on 1