Finally got a shiny piece of hardware that will make me a little happier with this power steering conversion. Should have done it this way from the beginning. Oh well.

If you recall, I originally did the FJ55 column, because at the time I wanted to try to do it with all Toyota parts. Well it’s been demonstrated that it can be done that way, but it is not optimal. The FJ55 column is 1 ½” longer than the FJ40 column, which puts it both closer to the driver, and high enough that on long drives it was uncomfortable to hold my arms up. FJ55 columns are also harder to find, I was just lucky to have found one at the moment I was working on that project. You also need FJ60 intermediate shaft components, which may or may not be easy to source depending on where you are at and the timing of your project.

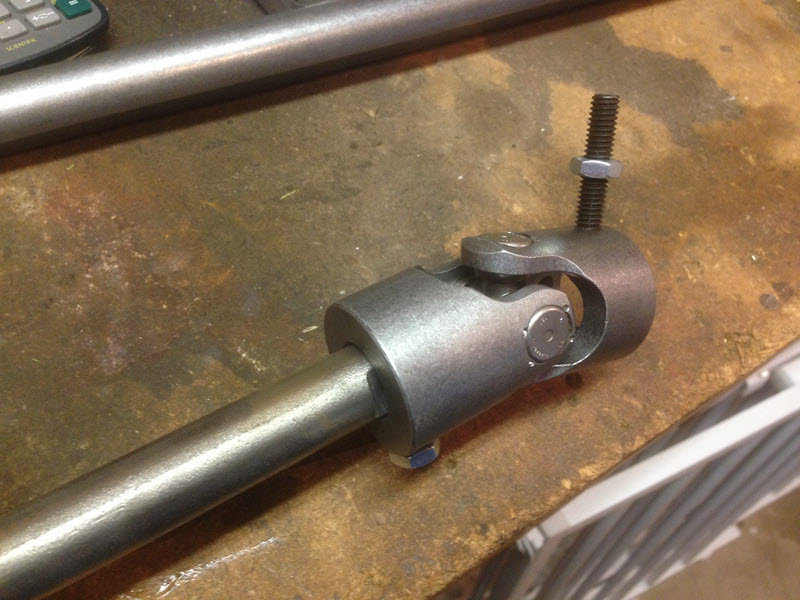

So for all these reasons I went back to the FJ40 column, and I’m going to use a Borgeson intermediate shaft on it. Borgeson shafts have nice tidy u-joints, have about 6” of slip joint, and are readily available. The FJ55/FJ60/Corolla u-joints on the Toyota intermediate shaft system are large and caused me to have to cut into my inner fender when I did the installation. If I had gone with a Borgeson shaft I wouldn’t have had to do this. Lesson learned.

I ordered a custom Borgeson shaft, after doing some searching around. The FJ60 steering box is a 36-spline, 17mm input. That’s REALLY close to the 11/16”, 36 spline available from Borgeson, and works perfect. On the firewall side, you cut the rag joint end off the FJ40 shaft and grind a “double D” onto the end of the shaft, which is basically two flats opposing each other. The shaft is 19mm, which is REALLY close to ¾”, so you can order a ¾” double D u-joint from Borgeson for that end. The length may vary, in my case the “c” dimension was 22” (see

http://www.borgeson.com/Designing/shaftlengths.html). That’s all you need and they will send you a shaft in a few days.

I cut the rag joint off close to the seam where it’s connected.

New shaft:

New shaft and old shaft compared:

Grinding the double D: the distance across the flats was 9/16” in my case:

Test fitting:

You also order the column support bearing from Kurt at Cruiser Outfitters (

http://www.cruiseroutfitters.com/powersteering.html), because the OEM bushing will disintegrate upon removal, and you smooth down the shaft just a tad so you can slide/tap the bearing in.

Steering column re-installed and ready to receive the intermediate shaft:

The Borgeson shaft will arrive a little long, and comes with instructions on how to shorten it up properly. Amount of material I removed:

One thing I did which is not mentioned in the instructions is I drilled small dimples for the set screws to seat in. I reasoned that this will help prevent the shaft from slipping out on a 4x4, whereas it may not be needed quite the same on a street rig. Can’t go too deep as the set screws don’t have much excess length to work with. Overall, nice, well-built, shiny hardware and good instructions, very happy with the product!

Painted and ready for install: