Interesting though, if I go for a tank (from Kilby anyway), they have a MAWP of 150 psi. So the 185 psi relief valve is no bueno.

http://www.kilbyenterprises.com/tanks.htm

I have thought about how to tap the head for alternate threads. Haven't been able to figure out a good solution yet.

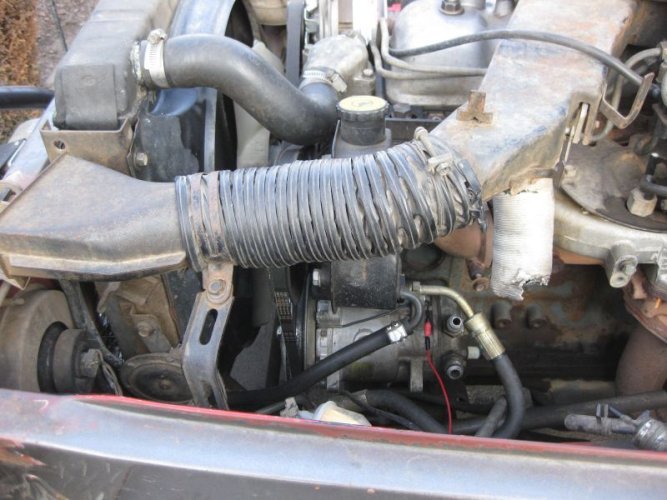

I still think I have the 45 degree flare (SAE) on this compressor. The -AN fittings are 37 degree flare. I don't know how to tell exactly what I have, some research I've done says that OEM applications didn't come with -AN, only SAE. You can go from SAE to NPT and back to -AN, but not directly from SAE to -AN. Most of the stuff you can buy from Jegs, Summit, etc. are -AN. Which makes me wonder why did Jegs, Summit, etc. settle on -AN if indeed OEM applications didn't use -AN? It doesn't make any sense.

Another thing, is that both SAE and -AN are tubing based, whereas NPT is obviously pipe based. And all this stuff is limited to about 5/8" or 3/4" sizes on the large end, you don't really see anything larger than that. So the options are somewhat limited depending on what you're trying to do.

sigh.

I'll just throw something together and if it leaks I'll know I made the wrong choice and I'll have to go back and fix it

In all reality, I think I do have a plan though