What is happening is the speed sensor is passive, just an AC waveform that more or less drives the speedometer, probably with just a linear amplifier to drive the motor (e.g. a voltage or current follower).

You could feed that AC sine wave into the ECU but the "error" they talk about is due to how a digital system sees signals. It wants to see voltages as either high or low. You can't hang out in the region between low and high without causing issues (called the switching or threshold region).

But if you impose a sine wave over a square wave you'll see that sine waves produce exactly the wrong type of signal for a system that wants to be either high or low. They actually spend almost no time as either zero or max and spend all the time slowly changing between them.

Without going into an even deeper tangent about digital design just realize that sine waves are terrible to feed into a digital input if you want to accurately represent it. Especially so when the signal you're reading is to measure frequency, e.g. counting the edges.

The basics here is if your signal is neither low (e.g. zero volts) or high (say 5V) and sits in between a digital input will randomly see it as low or high or might just oscillate between them until the right stable low or high is reached. The ECU might see a 15 Hz (just say it's on that order) speed sensor sine wave as going 500 MPH if it expects a 15 Hz square wave.

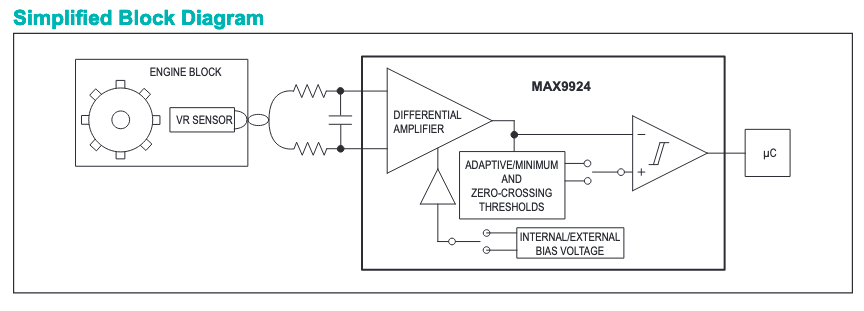

So you have to make the sine wave into a square wave. That's what the "conditioner" box is doing. It's making a slowly changing signal into one that changes very fast.

I'd probably shy away from modifying you gauge cluster unless you can figure out the circuit. It might still work fine or not. Potential problems is your speed stops working or begins to have errors or jumps around. It might also be unseen problems but is slowly ruining the speedometer motor. So I'd keep the VSS-to-gauge circuit as Toyota intended it personally.

I'd rather tap the VSS signal and use the conditioner. It wouldn't have to be on the gauge necessarily (like put a 'Y' in the harness at the VSS) and it wouldn't be difficult to hack something together if you can't find an OTS solution. At high level the circuit is very simple. The concept has been around since Moses was an EE undergrad.