One would think. So yeah pretty far fetched.Would unmetered air cause mixture (I'd think a lean burn) issues or a detonation, which those should throw codes?

O2 sensors are in spec for resistance per the FSM.

One would think. So yeah pretty far fetched.Would unmetered air cause mixture (I'd think a lean burn) issues or a detonation, which those should throw codes?

I have read that 1qt/1000 miles is acceptable, so 1 qt/5000 miles seemed ok in my mind. I'll look into that some more.@subzali If you had a massive leak you would have codes and running problems. I’m going to go with your cats are clogged. I think in another post you’ve said that you’ve been burning oil, 1 qt/ 5000 miles, that’ll do it. Not building boost because it can’t exhale and let the turbine wind up the compressor. We’ve had this on a few of our own turbo installs. We disconnect our downpipe from the rest of the exhaust and find the lost boost every time.

If you don’t have any codes and all emissions monitors are in the “ready” state then borrow someone’s 35” tires and go test at a station that can’t run 35’s. They’ll pass you on the diagnostic plug in showing everything ready.

Doesn’t fix the issue but gets you time to figure it out before the next round.

1 qt/ 1000 miles is definitely not a healthy motor and would be in need of a rebuild. If you're sticking to 5000 mile oil change intervals that's replacing 62.5% of your oil before the oil change and even 1 qt per 5000 is 12.5% consumption which also isn't great. 1FZ in good shape should have zero consumption. 100K on a rebuilt 1FZ in my 80 and there is no visual change in level on the dipstick between 6-8K mile intervals. Healthy 80's don't burn oil and once a cat is compromised by oil it wont take long for it to not work properly. @MonPetiteShoe just recently did his valve stem seals at 260K and now doesn't burn a drop between changes and he passed emissions no problem.I have read that 1qt/1000 miles is acceptable, so 1 qt/5000 miles seemed ok in my mind. I'll look into that some more.

The best way to check O2 sensors is with a scan tool that can graph o2 voltage vs time. There are a bazillion videos explaining this, so I won’t bother here. Essentially you’re looking at peak voltages, and responsiveness.So with my recent emissions failure I checked some things out today. The EGR modulator is not behaving per the FSM. But if it has failed wouldn’t that throw a P0401?

View attachment 140249

Step 6 here.

Also step 2 here

1. Replaced spark plugs, cap and rotor.

2. Adjusted timing. It was slightly retarded, maybe 2.5 deg instead of 3. I almost left it but wanted that notch dead on the 3.

3. Checked the EGR modulator per above. Still head scratching that one. Might buy a new one just to try and have on hand.

4. Washed the air filter. I think I’m done with the washable air filter. I think it’s cool and all but I think I will just buy new regular ones when needed.

5. Checked the EGR valve. Works like a champ.

6. Checked the temperatures of the cats. Outlet is about 150 degrees higher than the inlet, so that seems good.

7. Put some Lucas fuel injector cleaner in and ran up 285 to Bailey and back.

8. Checked spark plugs wire resistance. Well within spec.

I dunno

I just re-loaded my test reports to my two previous posts, with graphs. Thanks Jackson!I was going to add that sharing the graph of the failures can help. The graphs aren’t incredibly helpful unless there is a really out of normal graph. If the mean numbers are being driven up by giant spikes, it can be helpful to diagnose different things.

There is no real smoking gun in my opinion, but some things maybe worth investigating further.I just re-loaded my test reports to my two previous posts, with graphs. Thanks Jackson!

I did notice that the high NOx spikes seemed to follow a period of acceleration. That's about all I could get out of the graphs and not sure exactly what that would mean?

@jps8460 , is this what I need to check? Its not in % so not sure how to convert to your languageThere is no real smoking gun in my opinion, but some things maybe worth investigating further.

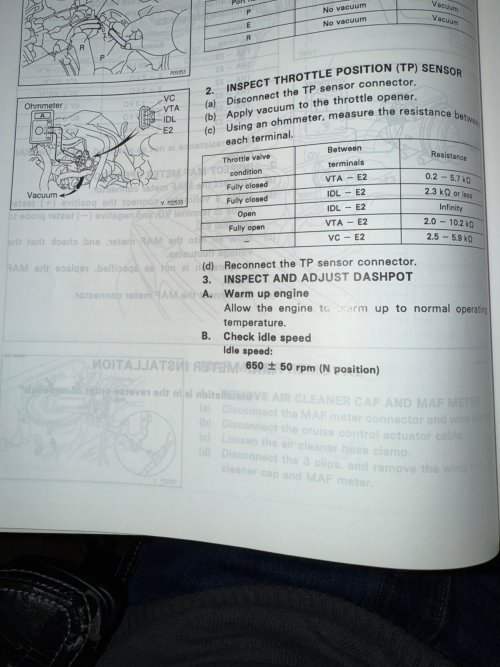

Sec 0092 is either idle in gear or coming off idle to accelerate. So thus is not necessarily a solid diagnostic indicator but…. A TPS of 14% at idle is high, this should be in the 8% range. A mis-adjustment is possible especially since STFT is neg 3%. So I'd double check that it’s set properly.

Generally when you see NOx, CO, and CH all spiking “abnormally” together It can be a sign of weak cat efficiency. If you look at your b1s2 sensor voltage matching your s1 voltage it could also indicate a cat efficiency issue. However, you’d really want to graph both of them side by side. The fact that it’s actually fluctuating is a good sign both for the sensor and the cat.

If all you had to go off of was that result and no other diagnostic equipment, I’d double check TPS, put premium in it, maybe pull some timing (this may cause your HC to go up boo hiss), drive it to the furthest away station from you and retest in hopes that the cats are a bit hotter and more efficient.

After that I’d replace a cat and see if it got better haha.

Yea, you’d need a scan tool to see %. But if you use that method it will net you the same results.

Yep it’s the same. EG-158 in mineThis should be just past that section. This is for an early truck. Double check your manual to make sure they are the same.

Well I hooked up a different vac/pressure test gauge and my turbo is making boost just fine. Around 5-6 psi like it should. So I think it’s just my in cab boost gauge that’s malfunctioning.@subzali If you had a massive leak you would have codes and running problems. I’m going to go with your cats are clogged. I think in another post you’ve said that you’ve been burning oil, 1 qt/ 5000 miles, that’ll do it. Not building boost because it can’t exhale and let the turbine wind up the compressor. We’ve had this on a few of our own turbo installs. We disconnect our downpipe from the rest of the exhaust and find the lost boost every time.

If you don’t have any codes and all emissions monitors are in the “ready” state then borrow someone’s 35” tires and go test at a station that can’t run 35’s. They’ll pass you on the diagnostic plug in showing everything ready.

Doesn’t fix the issue but gets you time to figure it out before the next round.

at idle, throttle position is 12.2%. FSM says 7-11%. I will adjust as soon as I can.There is no real smoking gun in my opinion, but some things maybe worth investigating further.

Sec 0092 is either idle in gear or coming off idle to accelerate. So thus is not necessarily a solid diagnostic indicator but…. A TPS of 14% at idle is high, this should be in the 8% range. A mis-adjustment is possible especially since STFT is neg 3%. So I'd double check that it’s set properly.

Generally when you see NOx, CO, and CH all spiking “abnormally” together It can be a sign of weak cat efficiency. If you look at your b1s2 sensor voltage matching your s1 voltage it could also indicate a cat efficiency issue. However, you’d really want to graph both of them side by side. The fact that it’s actually fluctuating is a good sign both for the sensor and the cat.

If all you had to go off of was that result and no other diagnostic equipment, I’d double check TPS, put premium in it, maybe pull some timing (this may cause your HC to go up boo hiss), drive it to the furthest away station from you and retest in hopes that the cats are a bit hotter and more efficient.

After that I’d replace a cat and see if it got better haha.

Are you able to graph the o2 voltages? This voltages are a good indication, but it’s helpful to see them oscillate. At idle B1S1 should be oscillating at around .5-1Hzat idle, throttle position is 12.2%. FSM says 7-11%. I will adjust as soon as I can.

STFT goes from -0.8% to -2.3% in cycles. Not sure how that is or is not impacting.

O2 bank 1 sensor 1 fluctuates between .04 and .75V. So seems ok?

Yeah it is oscillating at about that frequency. I will see if I can get a graph of it tomorrow.Are you able to graph the o2 voltages? This voltages are a good indication, but it’s helpful to see them oscillate. At idle B1S1 should be oscillating at around .5-1Hz

Cool. O2 sensors are probably doing their job then.Yeah it is oscillating at about that frequency. I will see if I can get a graph of it tomorrow.