kurtnkegger

Rising Sun Member

Since it looks like Mike will be taking a bit of a break from his 40, and the thread on his build, I thought I might as well chime in with the work I'm doing on my Sisters 40.

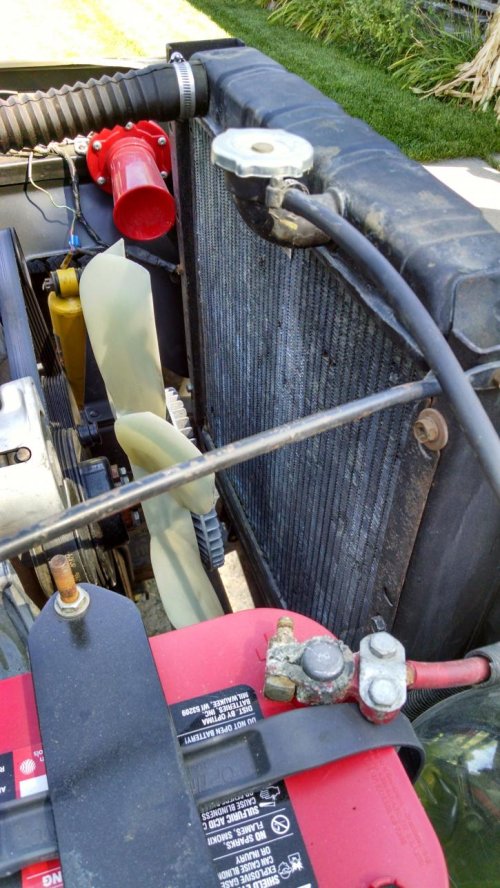

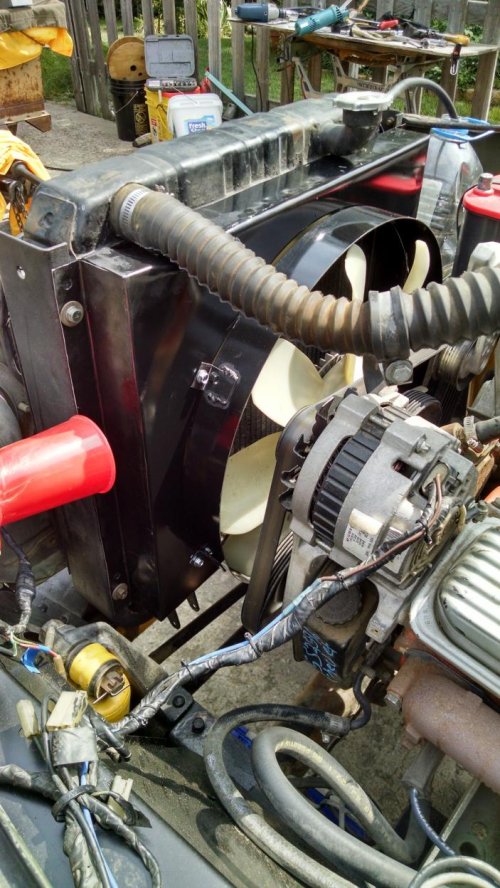

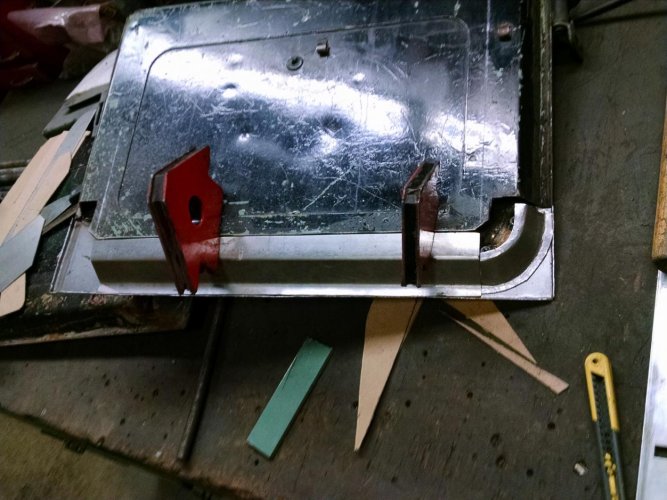

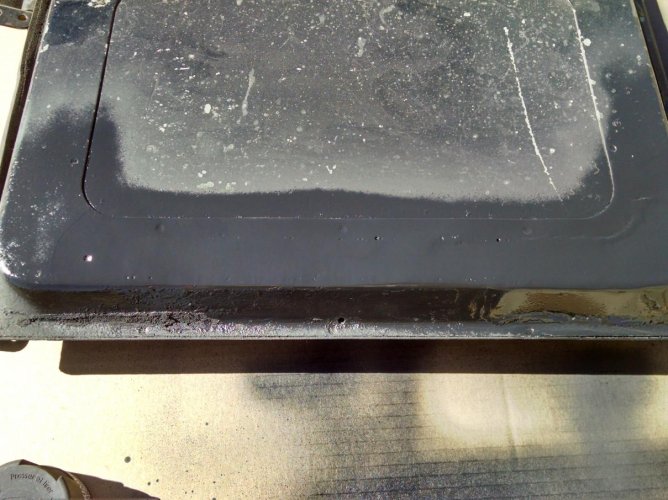

Here's a little back-ground...About 5 years ago, my sister bought her husband a '71 FJ40. He has always admired my '77, and liked the idea of having a classic trail rig. She had Merle trailer it down to his place in Salida for some restoration work. Her 40 had a 305 Camaro engine installed and mated to the original 3 speed transmission. With the sale came a SM465 transmission which she had Merles crew install, as well as newer axles for disc brakes in the front, a Toyota power steering set up, and an OME springs with a 2 1/2 inch lift. She had them install a roll-bar as this 40 will spend most of its life topless (which I'll post pictures later) with intent of them installing new fenders, rear quarters, and other parts...

This happened during the time when Merle's wife fell ill, and production started grinding to a halt in Salida...Then Merles horse apparently rolled over on him breaking bones, when everything stopped all together... Anyway, long story short, Merle had her Cruiser for a little over 3 years, and got a small amount of progress done on the 40. She had it towed back to my place, where I agreed to give it a little love.

on to a couple of pictures...we all love pictures...

Here's a little back-ground...About 5 years ago, my sister bought her husband a '71 FJ40. He has always admired my '77, and liked the idea of having a classic trail rig. She had Merle trailer it down to his place in Salida for some restoration work. Her 40 had a 305 Camaro engine installed and mated to the original 3 speed transmission. With the sale came a SM465 transmission which she had Merles crew install, as well as newer axles for disc brakes in the front, a Toyota power steering set up, and an OME springs with a 2 1/2 inch lift. She had them install a roll-bar as this 40 will spend most of its life topless (which I'll post pictures later) with intent of them installing new fenders, rear quarters, and other parts...

This happened during the time when Merle's wife fell ill, and production started grinding to a halt in Salida...Then Merles horse apparently rolled over on him breaking bones, when everything stopped all together... Anyway, long story short, Merle had her Cruiser for a little over 3 years, and got a small amount of progress done on the 40. She had it towed back to my place, where I agreed to give it a little love.

on to a couple of pictures...we all love pictures...