Shark Bait

Rising Sun Member

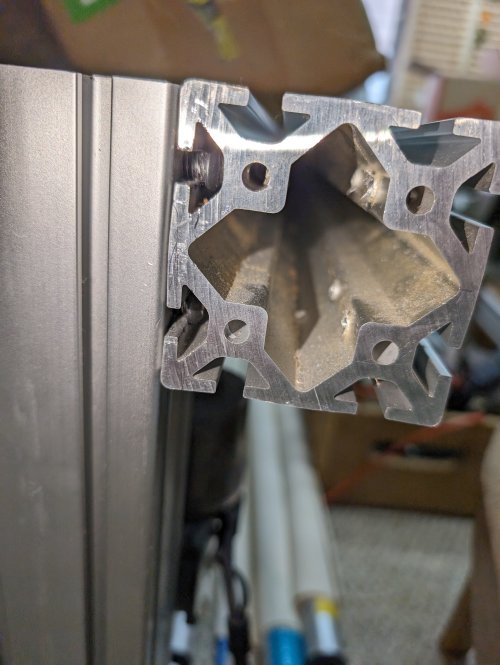

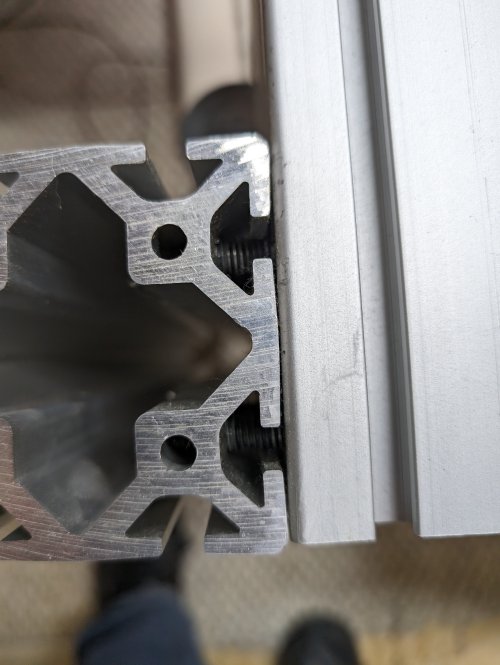

I have somewhat of a unique situation I need some help with. My (soon to be ex-) wife's longarm sewing table is aluminum beams and legs that are bolted together with steel Allen head bolts. We need to take it apart because, with the divorce, we are selling the house and moving. For lack of a better term, the bolts are "captured". They are inserted through the inner wall of the beam and bolt into threaded holes in the legs. The only way to tighten or loosen the bolts is to feed the Allen wrench through the hole in the outer wall of the beam. 4.5mm seems to be the right size for the Allen bolt heads. For the bolts we can get the wrench in to, we can loosen the bolts some, but then they bind like a rusty bolt. Sounds familiar? LOL. Some of the bolts we can't even get the wrench on the head. We think maybe the holes in the legs weren't quite true when they were drilled and tapped, just enough to prevent the wrench from inserting into the hole on the top of the bolts. They could be a different size hole in the head, but that's doubtful. There is at least 1 bolt like that on 3 of the legs. I put some PB Blaster on them, which didn't help right away. I'll be back over there in a couple of days to work on it again. We've sort of settled on drilling the heads off through the holes in the beams. We need to do this because the beams are 12 feet long and we need to take this thing apart to get it out of the basement. At some point in time she will want to re-assemble the table or sell it, So it would be nice to be able to remove all the bolts. Does anyone have any ideas? Or do any of you think you could fix this? I am hoping to avoid drilling them all the way out and re-tapping because there is only so much room in these beams. Might have to do some extra work to use different sized bolts. Maybe another piece of metal could be welded to the bolt heads. Then would heat work in this case to try and back them out? Any help would be appreciated.