rushthezeppelin

Rising Sun Member

- Joined

- Oct 14, 2022

- Messages

- 1,165

That's an idea!!Maybe put a bolt in it with a large washer to keep it flat, then try to bend the tab with pliers or similar?

Yup it worked!Maybe put a bolt in it with a large washer to keep it flat, then try to bend the tab with pliers or similar?

Well played good sir 😂. Not going to lie the thought crossed my mind.step by step instructions can be found here

I think your right. That one actually had two welds after looking closer but yeah it looks like a few of them have been replaced. Pretty sure I'm not the first one to wheel this truck and that's where the tabs usually get bent.A concern I'd have is the way yours are put together. There should be 3 spot welds holding the plate on from the factory and not a single weld at the top. If I was guessing someone before you broke it and the fix was less than ideal.

There's a gotcha with these kits. You lose the infinite cam and only get 3 positions for the lower arm. For a truck that's primarily for trails this is sufficient and no worse (maybe better) than a driveway alignment.i'm going this route eventfully on our 3rd gen

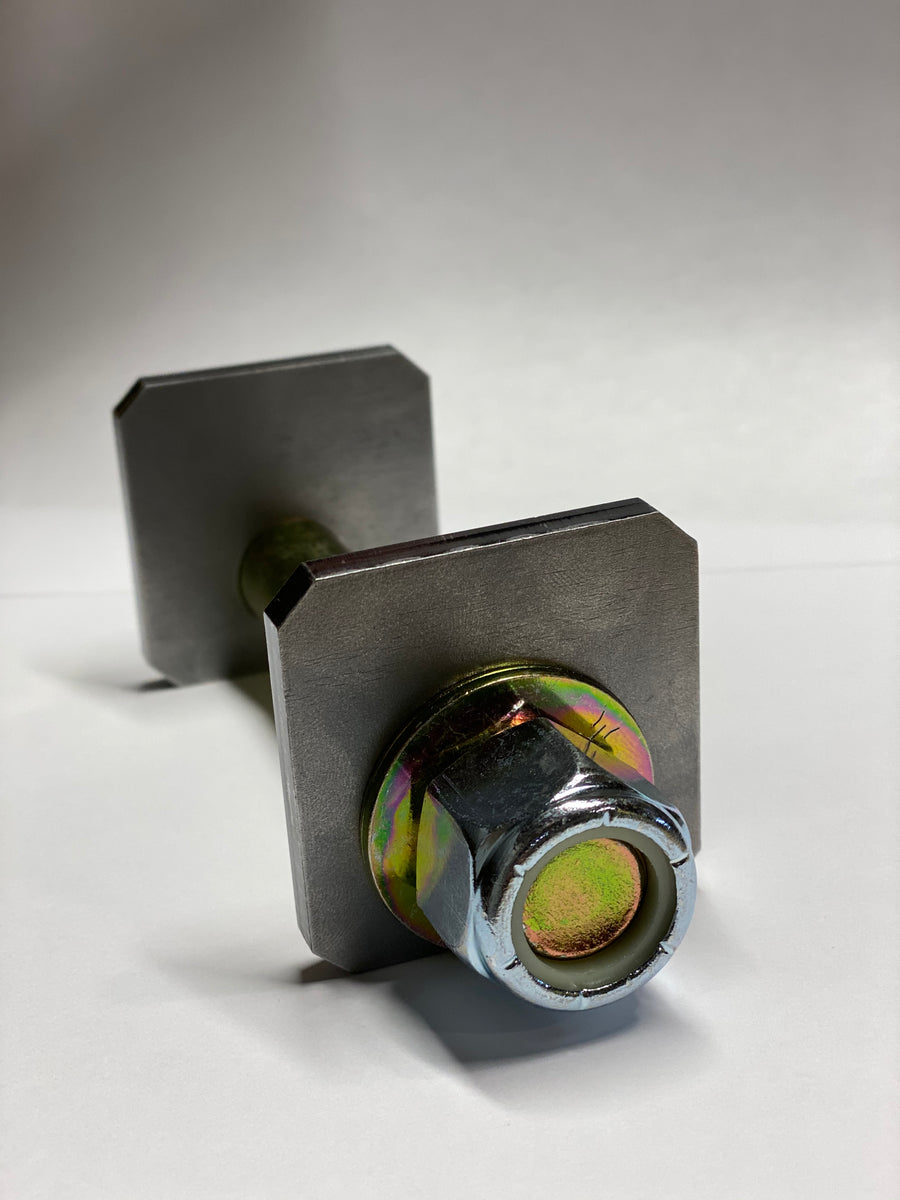

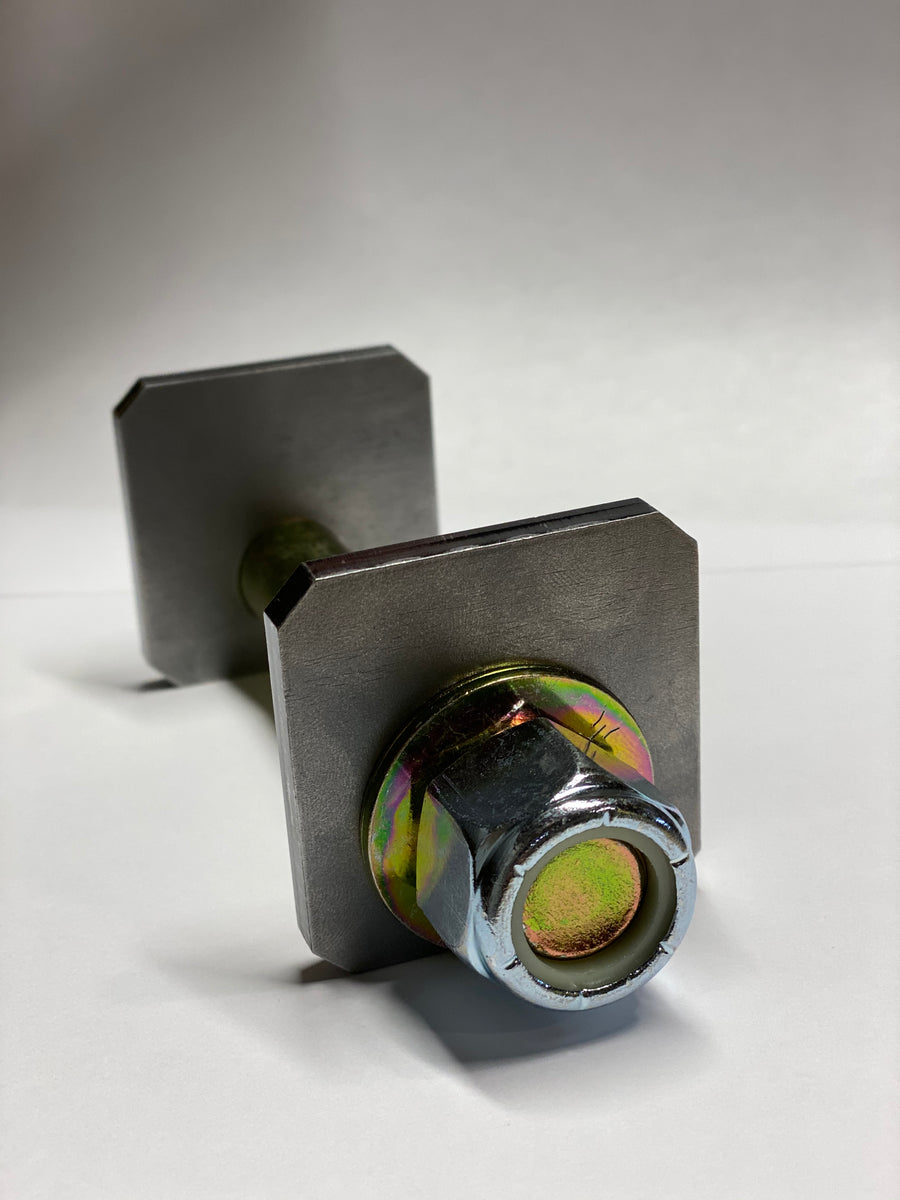

Cam Eliminator Kit

The Cam Eliminator Kit is your Toyota alignment fix! If you're tired of throwing off your alignment every time you go off-road, the Cam Eliminator Kit is your solution! See the difference for yourself and stop wasting time and money going to the alignment shop after each wheeling trip. Get...333fabrications.com

This, I think the octagonal cam eliminators are a better choice if you want to avoid losing alignment but have better adjustability. TBH though as long as your alignment tech gets the proper torque there should be enough clamping force to not lose alignment, I never lost alignment from offroading on my rig. It also doesn't eliminate the possibility of taking a hit like Adam or I did and flattening a cam tab. Only tab gussets or a fat weld bead will do that.There's a gotcha with these kits. You lose the infinite cam and only get 3 positions for the lower arm. For a truck that's primarily for trails this is sufficient and no worse (maybe better) than a driveway alignment.

But for a truck that does a lot of highway you need adjustable upper ball joints and an alignment tech with some experience to maybe dial it in. With regular fixed UCA it's going to be tough to get neutral handling and minimize tire wear. Those cams are doing both camber and caster on our trucks.

Now based on my alignment record having just min/mid/max for the lower arms is probably not going to make alignment outcomes any more of a crap-shoot. So there's that.

I don't think my fsm marks them as not reusable. I think the issue is that most alignment techs aren't going to get them to the 96ftlbs torque spec because the rack is legit in the way of getting an actual torque wrench in there. The probably just hand ugga dugga it as much as they can with a crescent or a box wrench. I ended up checking checking torque on all 4 while I had the rack out of the way and the front two were fine but the back driver was actually a little under spec. That said it did survive a hard hit on Yankee 2 1/2 weeks ago on the ice shelf that took out Andy's ring and pinion Saturday. I think the only way to truly torque them properly is with (at least in the case of 3rd gen 4runners) use a 22mm crowsfoot and do the calculations for the increased length.True, those alignment tabs should not be holding anything and the clamping force should be sufficient under normal use. I think loosening the bolts too much, tweaked frames and rust result in having much more difficulty getting them to turn and a mechanic reaching for a longer bar is certainly the most likely reason they bend.

But we push trucks considerably harder than the factory assumed when we rock crawl, put on lifts, change bump stop (and travel) and larger tires. So having thick or reinforced tabs isn't wholly without merit. It's my experience that alignment does seem to drift over time even without obvious damage. But it's only really when you've put in a double case or lower gears, run >33", etc and routinely hammer it. I've had trips coming home that the truck got a new pull to the shoulder even with a IFS brace and Budbuilt skid.

IOW when you've pushed the IFS geometry to the design margin. You can only torque the bolts so much before they stretch (are these marked non-reusable in the FSM by chance, I don't remember) so there's a limit on clamping force. Toyota balanced this against the forces they expected to hold against. Eventually something can slip.