mikedrom

Rising Sun Member

- Joined

- Jun 7, 2023

- Messages

- 96

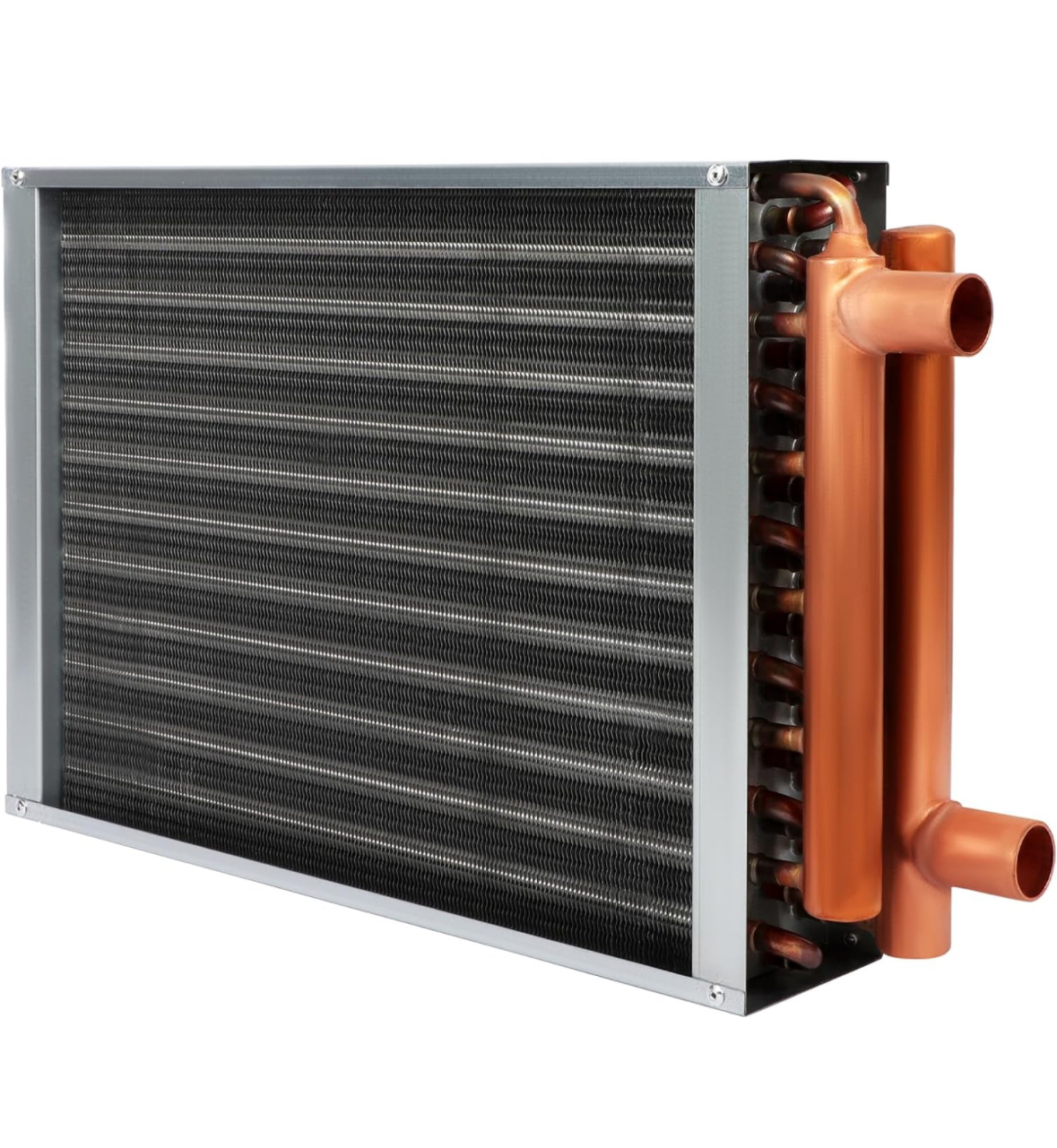

I’m working on a new air compressor build for my garage, and I want to add an after cooler between the pump and tank of my air compressor setup. Dozens of creative folks have uploaded pictures of their intricate coolers—pipes spanning entire walls, coils submerged in Home Depot buckets, etc.—but for my less-hardcore use, I’m thinking something much simpler could work: a furnace water-to-air heat exchanger with an electric fan strapped to it.

The temp, pressure, and CFM ratings for these all appear to meet what any shop compressor can muster up, but I’m assuming there HAS to be a reason I haven’t seen people using these. Dedicated aftercoolers for air compressors are also at least 10x the cost of these, so I’m guessing I’m missing something.

Someone want to talk me out of this idea before I accidentally blow myself up?

The temp, pressure, and CFM ratings for these all appear to meet what any shop compressor can muster up, but I’m assuming there HAS to be a reason I haven’t seen people using these. Dedicated aftercoolers for air compressors are also at least 10x the cost of these, so I’m guessing I’m missing something.

Someone want to talk me out of this idea before I accidentally blow myself up?