Stage 3 continued, baby steps:

Time has been scarce this winter as I've been busy with work, play and other projects (finally making some headway on the

Old Lady's 66' FJ45 build) but we had a few minutes of down time last week during the holidays and more importantly, the 200 wasn't buried in snow. This thing has needed brakes since day one, in fact I commented on the warped rotors to the seller (husband) and his reply was that his wife hadn't mentioned a thing about it. I laughed and said

"they never do". They were not horrible but when braking at 60+ mph hour speeds there was definite shimmy that needed to go away. I had conceded to using stock OEM rotors and our aftermarket AISIN pads (same as OEM other than box color and price) but I started investigating higher performance options even before I had ordered the first part for the build. Performance 360 kept popping up on my radar and we had been impressed by a set we recently installed a customers FZJ80, so why not give them a go?

I chatted with the gents at Performance 360 and things snowballed, the next thing I know we had a full stock order worked out, all of their front and rear LC applications. We ordered most in the native zinc/silver coloring but I did snag a front and rear set of drilled and slotted rotors with a black coating for the 200. While the front wheels were of off to swap rotors, it was also perfect time to install Spidertrax 1.25" wheel spacers. I hadn't included these in my original build parts list but following the suspension and wheel/tire install, I felt the front end needed a tad more width. Many have reservations about wheel spacers and a number of diatribes have been offered about them one way or the other. I've been running them for a long time on my 100 and other rigs previous to that, I've got customers who have been running them for 10+ years. My diatribe, a quality spacer, properly installed and periodically maintained is a non-issue. Your results may vary so take it for what it's worth. Rotor's on later model Land Cruisers are super cake to do, like 2 bolts on the caliper, slip the old rotor off, the new rotor on and you're done. We knocked out the fronts rotors and spacers and went back to work on paying projects.

Front Performance 360 drilled/slotted rotor & Spidertrax spacer

This afternoon offered a bit of shop time to finish up rotor upgrades, we swapped the rear, inspected and adjusted the park brake and snugged it all back together. The rear is also a slip-fit rotor but the caliper assembly has a couple of additional bolts you have to deal with but nothing major. The brakes weren't the only shudder I wanted to resolve, both side mirrors had an annoying shake at highway speeds. Toyota is well aware of this and offers a repair "kit" to fix the issue. The kit consists of 3 new screws that incorporate a lock-washer and flat washer rather than the original integrated flat washer. It's a 5 minute job to swap them out and as the bottom mirror trim is likely to break when you access the screws, they include that too. If your 200 Series mirrors are wiggly, check out the

Mud thread that includes a copy of Toyota's Technical Service Bulletin (TSB) and the needed part numbers for repair.

Rear Performance 360 drilled/slotted rotor

So, what next? Drawers would be nice to get tackled but I wasn't feeling that energetic, the rear bumper would have to wait until I had more time. Snorkel it was. The 200 Safari Snorkel is very straightforward, the instructions are complete and they've made some pretty nice changes to the kit comp. Now, allow me a minute to preach if you will. There are a bunch of knock-off snorkels hitting the market that are nothing short of a direct copy of the Safari Snorkel. We know them well, as we move a fair number of snorkels each year we get suited by companies trying to sell us kits and through that process we can learn a bit about their R&D (or lack thereof), their customer service, tech support, spare parts availability, etc. I fully know that Safari Snorkel's cost 2-3x that of a no-name Alibaba solution but I also know I can call them if something doesn't fit, I can get a spare part if something fails in the future and I know their plastic is going to last 20+ years in the sun, in the snow and even on the rocks. Rant off, picture time!

Before

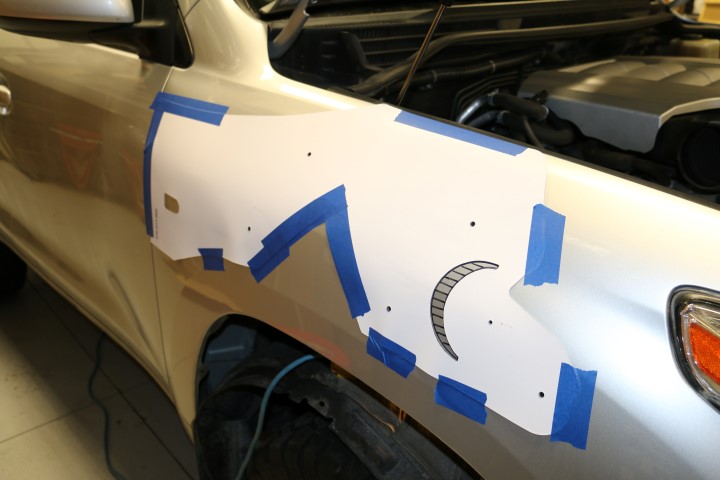

Template attached, holes marked

Holes

Bigger Holes

Finished!

Some detail shots of the process.

Closeup of the template and fender marking

A-Piller marking and drilling using a step-drill

The hose mounting between the factory airbox and snorkel body was giving us some fits so we ended up warming it up to make the rubber more pliable. That did the trick and it slipped tightly onto the factory airbox and did the needed contorting to adapt to the snorkel body.

The snorkel is just part one of the waterproofing process, I'll be using the ARB Differential Breather kit (part# 170112) to tie the gear boxes up to the breather manifold which will be mounted up high in the engine bay. Some other considerations on the snorkel install can be found in a

Tacoma Magazine article I wrote here.

One last pic to echo my earlier genuine Safari Snorkel comments. My buddy Greg laid his FJ40 on it's side in a Moab hot tub in the late 90's. He was sure the snorkel was going to be cracked. Nope, flexed right back into shape. 15 years later and that snorkel still looks and functions great on Greg's daily driver FJ40, Safari Snorkel for the win.