Very nice deep dive.

Often once people go to the prong and screw type ARB plug (or another type that is not cig lighter style with spring loaded tip) the ARB shutoff issue goes away. Can that voltage drop be tested?

It can. I know Romer and Corbet were just talking about that so it would be an interesting test. I don't know if I've ever seen a spec for what it's supposed to be, though. It would take very sensitive test equipment, a DMM probably would not read it. My current probes would not, although on mA a DMM shunt may get a rough value of it.

For comparison Anderson does give a spec for a standard PowerPole, which for the smallest terminals (15A for 16 to 20 AWG wire) is 875 μΩ. Note the prefix is micro-Ohm so it's 0.875 mΩ. The voltage drop at 15 amps for this would be 13.125 mV (it's small, 0.013125 V)

I wouldn't think a properly functioning cigarette plug is actually going to be all that much worse to be honest. They're rated for 10 amps in most cases and that would imply they'd expect tens of mΩ otherwise they'd be melting all the time.

So if I was to hazard a guess the main problem is one of two.

First is "properly functioning" is a

major assumption. Those things are prone to falling out from vibration and the springs losing their flex.

Second is corrosion. Legitimate PowerPoles are silver plated so fairly immune to most things. Cigarette plugs may be chrome, nickel (such as Blue Sea uses) or most anything shiny. Quality is going to vary I imagine.

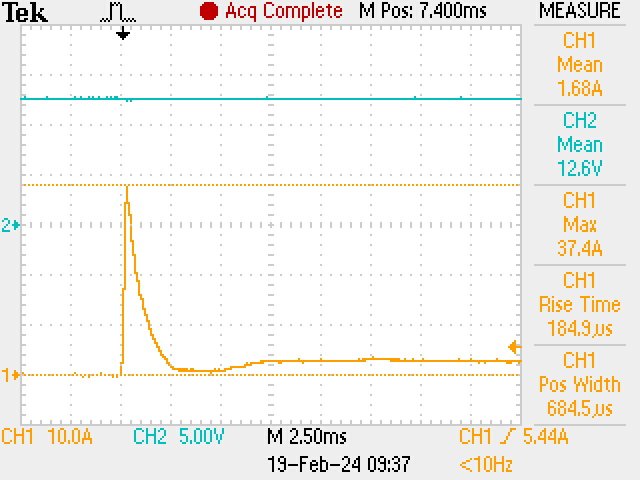

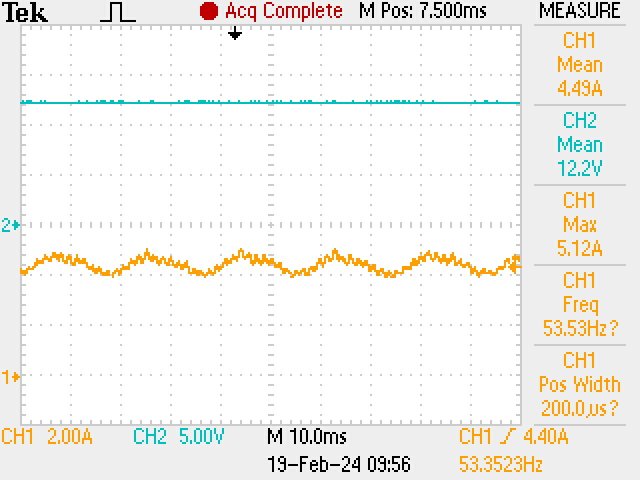

Overall, I am shocked by the 37.5 amp ARB 47qt inrush.

Don't read too much into that. Inrush is a matter of resistance (and impedance, strictly speaking), current and time.

More important, though, is impedance. Impedance is resistance of a device that operates on alternating current. The total current that flows is a function of

both DC and AC.

A motor winding (an inductor) has both resistance and impedance. So do electronic devices like capacitors and transistors. So the inrush on a circuit may have a very low initial DC resistance but once an electric or magnetic field builds up the impedance completely changes the amount of current flowing. Doesn't always mean the current goes down but usually that's the case.

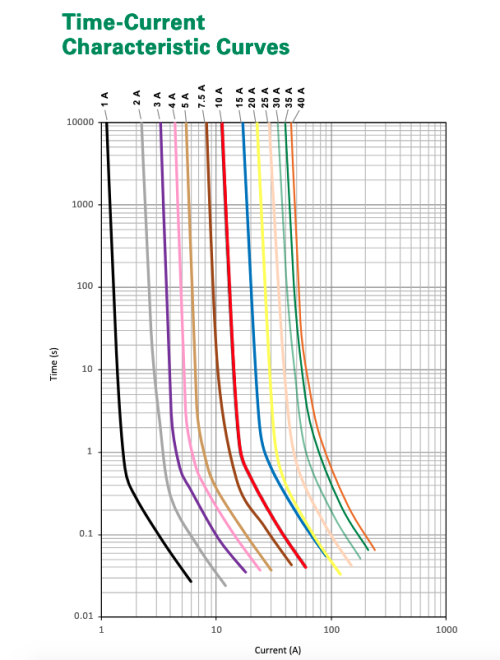

So look at the time for that inrush. It's

very short, 2/1000th of second. A fuse reacts in hundreds of milliseconds up to tens or hundreds of seconds, perhaps minutes or hours. For a fuse to trip in 2 millisecond would take probably thousands of amps. This is due to heating and heat is a function of current and time, exponentially.

Just to belabor the point. Think about your laptop power supply. When you plug it in after it's been sitting for a while you may get a small arc on the plug. That's inrush to the big caps in it. That doesn't hurt anything for the most part. That's basically what is happening with that ~37 amps when I turned on the fridge. All the "stuff" inside getting it's first power.

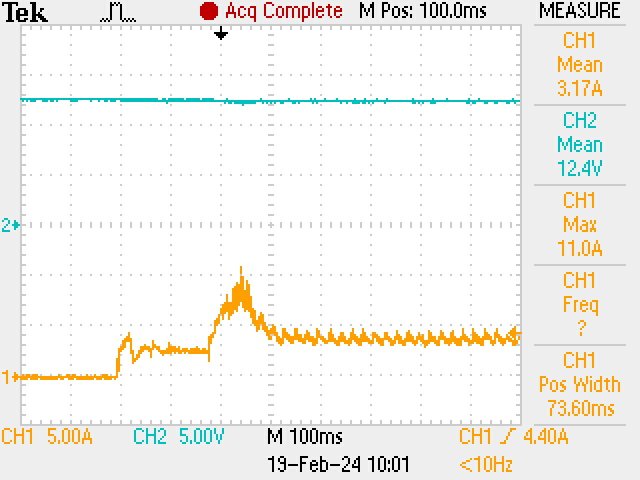

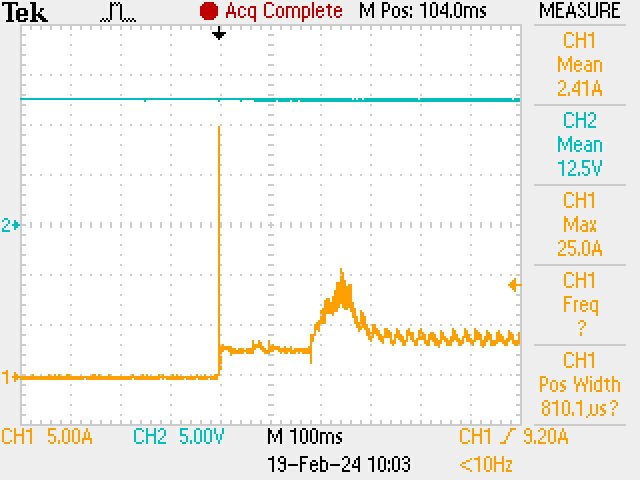

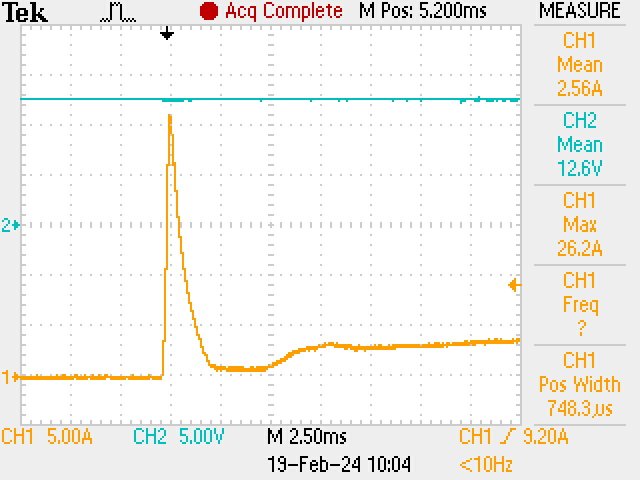

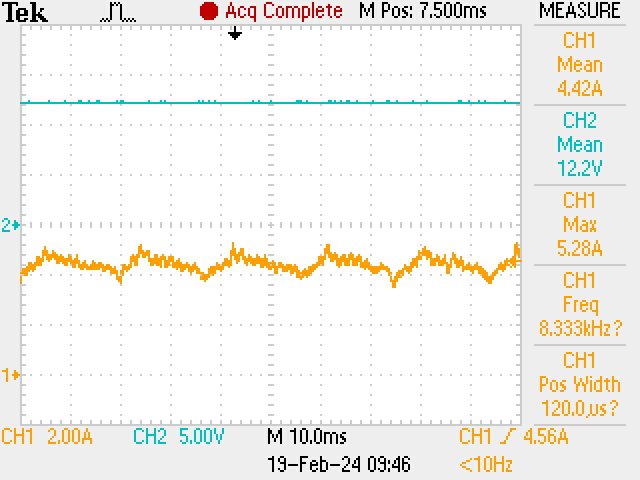

I was a little surprised by the ~26 amps when the compressor was going to turn on. The 11 amp surge when the motor starts I expected.

The Engel did that, too. It was lower but still significant. When you turn it on there's about 6 amps of inrush to the control circuit and each time the compressor starts it's about 12 amps of surge. If I was looking at this from my perspective as a designer I'd just say whomever did the Engel paid more attention to cap charging or perhaps mitigating FET inrush.

I don't want to suggest it's not important, cumulative or immediate damage can occur with any inrush. But it's also not surprising. Anecdotally, you know how some people say their whatever is left running forever while some people who turn them off seem to get less life? This is partially why. Turning on a TV or computer or fridge, or indeed starting your engine, is by far the most damaging time for it.