Long technical junk follows. You are warned, please no more PMs about it. If you don't want to hear it then please just stop reading and look at this relaxing mountain image for the next 5 minutes.

If you're still reading this time suck, here ya go.

Yes, mechanical relay contacts arc each time they are cycled. This is basically a mini spark ignition system. Relay manufacturers know this is potentially a problem, which is why the cases are sealed when they build them. Depending on how critical the application is determines how robust that seal is. Under the hood the fumes aren't super concentrated so it's not like underground mining or refinery. It's usually just glue or they melt the plastic around the edges. The flip side of this is debris and chemicals in the air can cause corrosion to the relay internals so the seals also prevents the relay from failing prematurely.

The concern I have with what you've done is the lifespan. Relays have what's known as normally open and normally closed contacts. This is the state of the switch when the relay is unpowered. When power is applied to the coil the contacts flip to their other state.

If a contact is normally open it's like a switch that is open so current cannot flow and the circuit is off. When the controlling circuit powers the relay it's actually energizing a coil to that a magnetic field can pull the normally open contacts to closed, completing the circuit and turning on the power. That's the click you hear, the magnet pulling the contacts.

When power is removed from the relay coil the magnetic field collapses and a spring mechancially pushes the contacts back to open. The coil creates a magnetic field that is strong enough to overcome the strength of that spring. It's a very old concept that hasn't changed in, I dunno, 150 years.

By jamming a piece of zip tie in their you force closed the contacts, which is fine. It makes the circuit electrically. But the spring is always pushing back against it. As you drive down the road heat and vibration and bumps are jostling the relay around. So the zip tie is slowly wearing down, which causes a tiny gap to start opening, like the relay is neither completely open or closed. Or it moves or falls out. It's a reliability question over time.

If you wanted to do it this way using a better material, like Delrin or something that won't slowly wear down is one improvement. Also gluing the jamming material in place might be a good idea. And then re-sealing the relay case, like maybe a line of super glue or something along the edge.

The jumper wire may look worse but it's better in terms of performance.

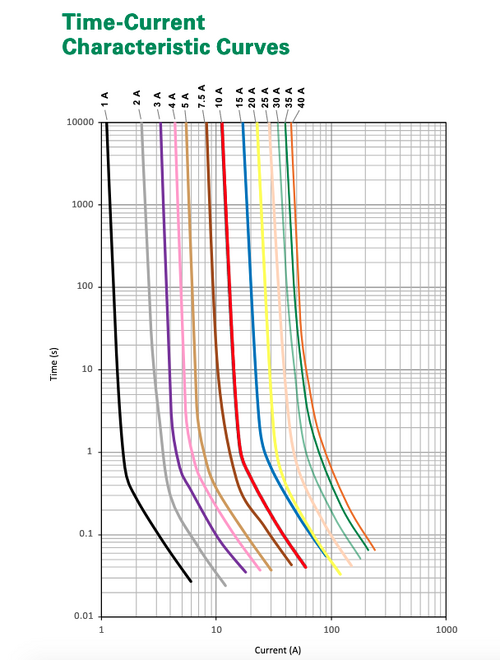

The factory outlets are rated pretty high, I think 20A and they are safe for that. The duration of in-rush when a compressor starts is short and the current is probably around 20A or so I'd guess. It's not a melt down issue for the most part, even with factory wiring left stock with the unmodified relay. The circuit is fused, too.

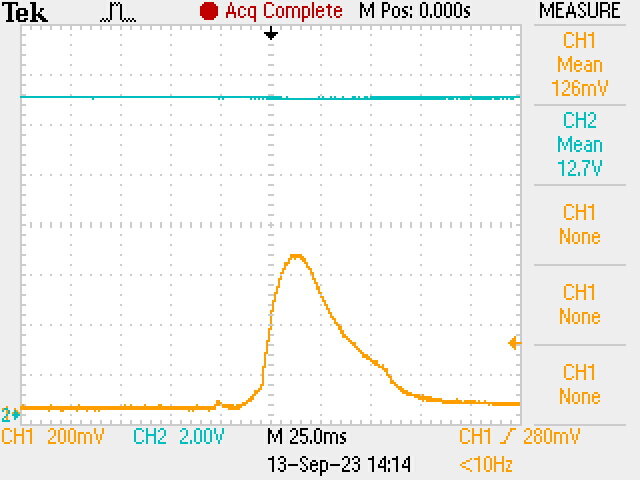

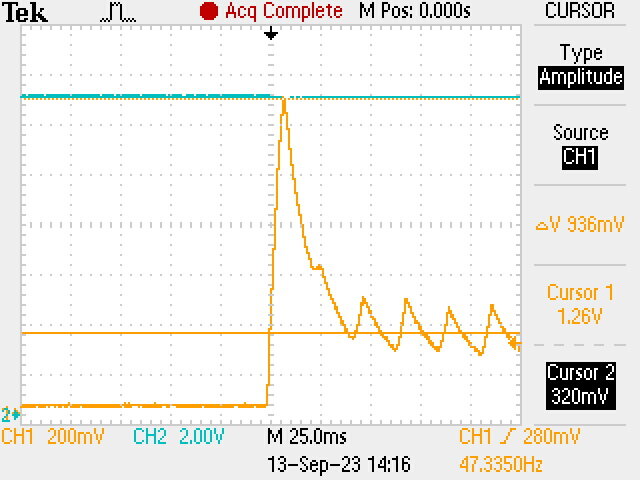

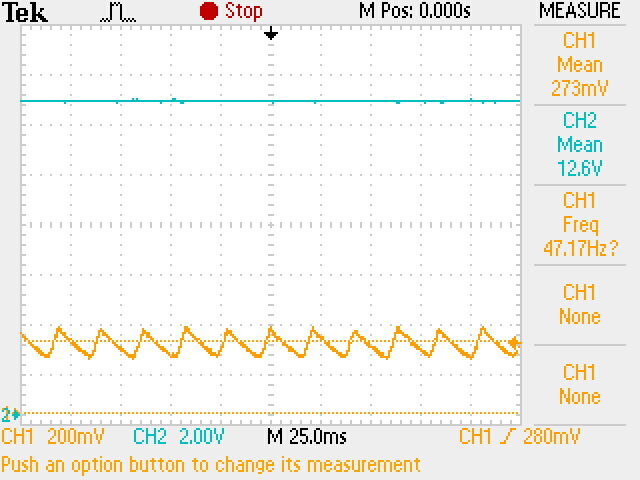

What I wrote was that if the voltage drop is excessive during start-up the fridge low voltage protection can kick in. Many fridges now have a battery protection that will turn them off if the battery gets low. Usually around 10.5V up to maybe something in the 11V range. If you have 20A of current through too small of a wire the instantaneous voltage drop could be a few volts and depending on how long the in-rush lasts and how sensitive the fridge protection is it might be enough to trick it. Then you get into a game where the fridge is constantly trying to turn on, the protection turns it off, the battery not really being dead has its voltage jump back up and the fridge tries again. On and on and on.