Rest the sharpie on a jackstand. There is usually a nice groove for a pen on the top of the cast ones.

I agree. I bet you are towed out too much.

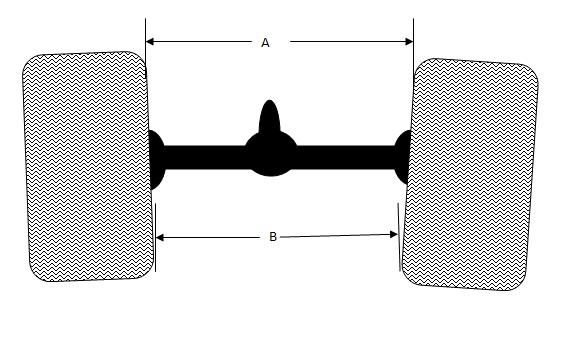

Me? I have a stick that is a little shorter than the width between my front rims. I put a deck screw in the end of the stick to make the length of the stick adjustable. Adjust screw to match width between rims in FRONT of the axle. Move behind the axle to measure the width between the rims on the BACK. Back should be about 1/16th wider than the front adjusted stick. Adjust tie-rod on truck if required. Roll truck out of and back into the garage. re-test.

We're talking about a TRUCK here, not the space shuttle.

I've tried other ways too. Like "stringing" the car NASCAR style. I was more accurate with the adjustable stick on the inside of the rims. My rims are pretty straight. I guess if you had wobbly, bent, deformed rims it wouldn't work unless you rolled the truck forward so you can measure in the same places with the stick behind the axle.

Caster and camber are tough to change on a solid axle. Adjust camber with a torch on the housing. Heat up the top or bottom of the tube, let it cool, repeat. You'll shrink the tube on either the top or the bottom to "adjust" the camber. On my Dad's solid rear axle mustang, this is how you "bend" the housing to get static negative camber on a solid axle. Tough on bearings and axleshafts? Sure but who cares?

Setting caster on the SAS is done by changing the length of the shackles. But there are limits to how long/short you can make those. Raise or lower the front leaf spring mount. Not easy. You can shim the spring perches or rotate the perches. All these are great, but it messes up your pinion angle! the only option that doesn't mess up your pinion angle is to cut the kunckles and rotate them.

Basically, no one adjusts caster/camber on these rigs.

I've also done the duct tape line, (actually, I just chalked the tire) but that involves jacking up the truck. Extra work for me!

TIP : Push a tack into a block of the tread to hold the far end of the tape measure since you'll probably be working alone after all, that is why they put that hole in the end of your tape!

On the racecars, we simply used "toe plates" just two flat rectangles of steel. Lean them against the tire with the tops touching the front and back of the tire around the centerline of the wheel. The distance the bottom of the plates are from the tires doesn't matter. Just lean them up there. Measure on the bottom of the toe plates on the ground. Race tires are pretty well built and uniform so it is actually pretty accurate. Being able to slide the tape under a very low car and hook the edge of the plate made it easy and fast to check total toe even when working alone.

After awhile, you'll be able to SEE correct toe just with your eyeballs.

My Dad simply uses toe plates on his Mustang racecar too.

(but let's face it the 1970 Mustang chassis is so "loose" that precise chassis setup isn't really going to buy you much!) "hang it out!"