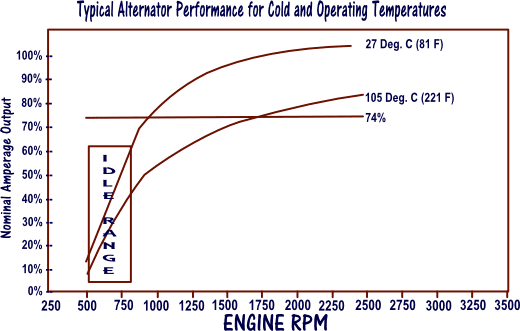

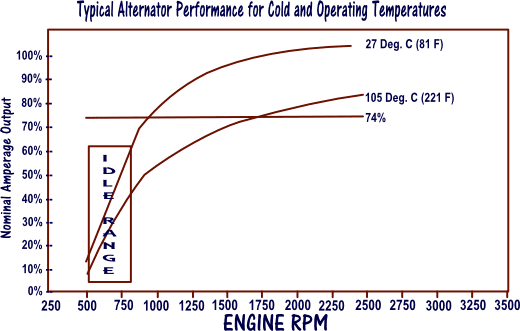

You are correct, an alternator follows a performance curve that results in increasing power as the RPM increases. You can wind them to work better at lower RPM but they will never be flat. You're also 100% on track to think about heat, which affects both reliability and output. Their output goes down as heat goes up.

And don't get into the bigger number game. Sometimes the alternator that is stock can do just fine over a wider range of RPM than a more specialized one. You can't really know without finding documentation, though.

Realize too that engine RPM does not equal alternator RPM. There's a pulley ratio that the OEM already thought of to spin it faster than the engine specifically to overcome this problem.

Why I mention this is Toyota also knows the max RPM the alternator can take without bearing failure. At redline the alternator will be spinning faster than the engine. A high output aftermarket alternator that increases low RPM ouput might not be intended to spin at the same max RPM as the stock one. Take for example big alternators are often used on diesel trucks, which might have an engine redline of 4k and you may inadvertently over spin it passing at the Tunnel if used on a higher revving gas engine. There again, need documents to know.

Your second issue is I think more important. One place where aftermarket alternators are usually better is duty cycle. Very rarely are original stock alternators expected to run at full load over extended time. The upside is at idle and lower power the alternator will make less heat, but at 100% duty cycle even lower power and almost certainly at running RPM heat high duty cycle could be a concern.

There's only so many ways to solve that. Ask for lower power, use better cooling. It might be enough to leave the hood up idling. Moving it's hard to say but air flow on the highway should help. I think ultimately it's just going to increase wear-and-tear as you use it more. All you can really do is see how it does and adapt. If it seems like it gets excessively you might have to figure out a way to use a true heavy duty alternator but I suspect that the stock one on a Cruiser is about as rugged as you can get without going to a dual alternator commercial truck approach.

That charger you're considering is 800 watts. That's a lot to ask over long periods. I went with a smaller Victron 18A, 220 watts DC-DC and even that's enough to slightly bog my Tacoma at idle (it's about 1/3 HP). You're considering 4 times that, which gets into about the same load as your A/C puts on the engine.

You know, honestly, look at what the car stereo guys do. A fair bit of it is sketchy but sometimes they find really novel solutions, particularly trying to get more power and better cooling at idle.