DanTheMan

Rising Sun Member

Hey Jeff, think you can make something like this?

https://www.ebay.com/p/Toyota-Fj40-Land-Cruiser-Cookie-Cutter-Landcruiser-Fj-40/2267234487

https://www.ebay.com/p/Toyota-Fj40-Land-Cruiser-Cookie-Cutter-Landcruiser-Fj-40/2267234487

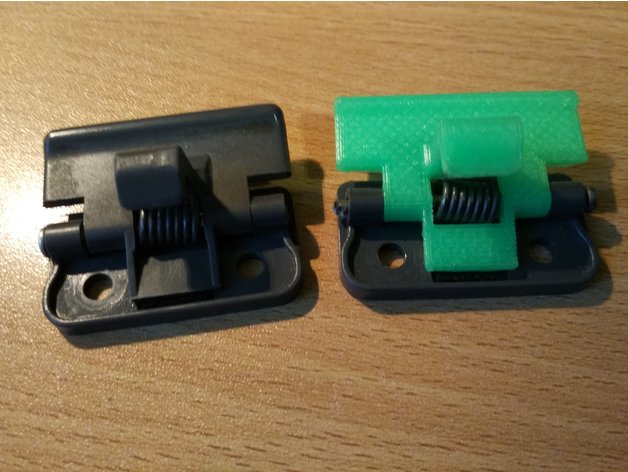

![IMG_0855[973].jpg](/xf/data/attachments/47/47884-b7edf6edcf102283c2599167ab639c74.jpg)